Abstract

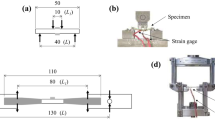

In this study, the axial compressive properties and fracture behavior of car-bon/glass thermoplastic epoxy hybrid composite rods were investigated. The hybrid composite rods are cut, then glass fabric/epoxy-composite wrapping is applied by the wet hand layup method at each end of the specimens. The results show that the induced strain is linearly proportional to the applied stress until failure. This test method is effective in evaluating the axial compressive properties of the hybrid composite rods. The test results reveal an increase in the axial compressive modulus and strength of the hybrid composite rods as the volume fraction of the carbon fiber increases. However, a decrease in the volume fraction of the voids resulted in an increase in the axial compressive strength and thereby an increase in the Weibull shape parameter. The observed fracture surfaces showed shear cracks of the matrix at the fiber bundle intersections due to the braiding structures. Observing the internal fractures also revealed the occurrence of the micro-buckling and fiber kinking of the carbon fiber bundles.

Similar content being viewed by others

References

S.C. Watson and D. Stafford, Cables in Trouble. Engineered Design and Construction, ASCE Civil Eng., 1998, 58(4), p 38–41

R.E. Hobbs and K. Ghavani, The Fatigue of Structural Wire Strands, Int. J. Fatigue, 1982, 4(2), p 69–72

P. Balaguru, A. Nanni, and J. Giancaspro, FRP Composites for Reinforced and Prestressed Concrete Structures: A Guide to Fundamentals and Design for Repair and Retrofit, Taylor, New York, 2009

U. Meier, Composite Materials in Bridge Repair, Appl. Compos. Mater., 2000, 7(2), p 75–94

A. Maissen, Concrete Beams Prestressed with CFRP Strands, Struct. Eng. Int., 1997, 7(4), p 284–287

U. Meier, Carbon Fiber Reinforced Polymer Cables: Why? Why Not? What If?, Arab. J. Sci. Eng., 2012, 37(2), p 399–411

B.M. Burks, D.L. Armentrout, M. Baldwin, J. Buckley, and M. Kumosa, Hybrid Composite Rods Subjected to Excessive Bending Loads, Compos. Sci. Technol., 2009, 69(15–16), p 2625–2632

E. Barjasteh, E.J. Bosze, Y.I. Tsai, and S.R. Nutt, Thermal Aging of Fiberglass/Carbon-Fiber Hybrid Composites, Compos. Part A-Appl. S., 2009, 40(12), p 2038–2045

B. Benmokrane, A.H. Ali, H.M. Mohamed, M. Robert, and A. Elsafty, Durability Performance and Service Life of CFCC Tendons Exposed to Elevated Temperature and Alkaline Environment, J. Compos. Constr., 2016, 20(1), p 04015043

E.L. d’Hooghe and C.M. Edwards, Thermoplastic Composite Technology, Tougher Than You Think. Adv. Mater., 2000, 12(23), p 1865–1868

Nagase ChemteX Corporation, Process for Production of Thermoplastic Cured Epoxy Resin with Transparency to Visible Light, and Thermoplastic Epoxy Resin Composition, United States Patent Application Publication, Pub. No. US 2014/0194590 A1, 2014

T. Imanishi, H. Nishida, N. Hirayama, and N. Tomomitsu, In-situ Polymerizable Thermoplastic Epoxy Resin and High Performance FRTP using It and Fiber Fabrics, In: New Resins and Their Composites, Proceedings of 16th International Conference on Composite Materials (ICCM-16), Kyoto, 2007, pp. 194–195

K. Naito and H. Oguma, Tensile Properties of Novel Carbon/Glass Hybrid Thermoplastic Composite Rods, Compos. Struct., 2017, 161(5), p 23–31

K. Naito, C. Nagai, and Y. Tanaka, Transverse Compressive Properties of Carbon/Glass Hybrid Thermoplastic Composite Rods, J. Phys. Sci. Appl., 2019, 9(1), p 25–33

H.M. Hawthorne, On Non-Hookean Behavior of Carbon Fibres in Bending, J. Mater. Sci., 1993, 28(9), p 2531–2535

W.S. Williams, D.A. Steffens, and R. Bacon, Bending Behavior and Tensile Strength of Carbon Fibers, J. Appl. Phys., 1970, 41(12), p 4893–4901

Z.P. Bazant, J.J.H. Kim, I.M. Daniel, and G. Zi, Size Effect on Compression Strength of Fiber Composites Failing by Kink Band Propagation, Int. J. Fract., 1999, 95, p 103–141

D.M. Montiel and C.J. Williams, A Method for Evaluating the High Strain Compressive Properties of Composite Materials, In: G.C. Grimes, editor, Composite Materials: Testing and Design (10th volume), ASTM STP1120, ASTM international, 1992, pp. 54–64

ASTM D695-15, Standard Test Method for Compressive Properties of Rigid Plastics, ASTM International, West Conshohocken, PA, 2015

K. Naito, H. Oguma, Y. Hayashi, T. Nakayama, and H. Noda, Fixing Structures of Fiber Reinforced Plastics Cables and its Fabrication, Strength Testing Methods, and Strength Testing Specimens, Patent, No. 2015-137928, 2015, (in Japanese)

W. Weibull, A Statistical Distribution Function of Wide Applicability, J. Appl. Mech., 1951, 18, p 293–297

B. Budiansky and N.A. Fleck, Compressive Failure of Fibre Composites, J. Mech. Phys. Solids, 1993, 41(1), p 183–211

J.K. Kim and Y.W. Mai, High Strength, High Fracture Toughness Fibre Composites with Interface Control-A Review, Compos. Sci. Technol., 1991, 41(4), p 333–378

Correlated Solutions Inc., VIC-2D, 952 Sunset Boulevard, West Columbia, SC 29252, USA

S. Dai, P.R. Cunningham, S. Marshall, and C. Silva, Influence of Fibre Architecture on the Tensile, Compressive and Flexural Behaviour of 3D Woven Composites, Compos. Part A-Appl. S., 2015, 69(2), p 195–207

V. Srinivasaa, V. Shivakumar, V. Nayakaa, S. Jagadeeshaiaiha, M. Seethrama, R. Shenoya, and A. Nafidie, Fractography of Compression Failed Carbon Fiber Reinforced Plastic Composite Laminates, Mater. Res., 2010, 13(3), p 417–424

K. Naito, Y. Tanaka, J.M. Yang, and Y. Kagawa, Flexural Properties of PAN- and Pitch-Based Carbon Fibers, J. Am. Ceram. Soc., 2009, 92(1), p 186–192

Acknowledgments

This research was promoted by COI program “Construction of next-generation infrastructure using innovative materials ~ Realization of safe and secure society that can coexist with the Earth for centuries ~ supported by Japan Science and Technology Agency (JST) Grant Number JPMJCE1315.

Author information

Authors and Affiliations

Contributions

KN performed experiments, wrote the manuscript and prepared the figures. CN prepared the manuscript. All the authors read and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The author(s) declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naito, K., Nagai, C. Axial Compressive Properties of Carbon/Glass Thermoplastic Epoxy Hybrid Composite Rods. J. of Materi Eng and Perform 29, 4804–4813 (2020). https://doi.org/10.1007/s11665-020-04981-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04981-w