Abstract

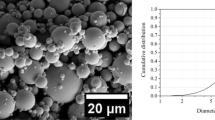

Typical metal 3D printing processes with powders require either a laser or electron beam as the heating source. In this work, an alternative non-expensive metal 3D printing process based on the fused deposition modeling process using metal filled filament is studied. Using bronze filament as a feedstock, the microstructures, phases, compositions of the filament, as-printed, and sintered specimens are analyzed. The 3D printing process basically does not modify the morphology and phases of the filament. Sintering temperature below 832 °C is recommended. Above 832 °C, there are substantial oxidation reactions leading to the formation of copper oxide and cassiterite shell structure around the bronze core. The mechanical properties of the 3D-printed sample are measured using the three-point bending test. The measured flexural strength is 27.9 MPa, and the modulus of elasticity is 1.2 GPa. This study provides important information for applying the bronze filament in future engineering applications.

Similar content being viewed by others

References

N. Hall, New filament means you can print metal on any 3D printer. 3D Printing Industry, 2019. https://3dprintingindustry.com/news/now-can-print-metal-3d-printer-85255/. Accessed 20 Oct 2019

O.I. Ayeni, Sintering and Characterizations of 3D Printed Bronze Metal Filament, M.S. thesis, Purdue University, 2018

VirtualFoundry, Bronze Filamet, 2018. https://www.thevirtualfoundry.com/bronze-filament. Accessed 20 Oct 2019

VirtualFoundry. Material Safety Datasheet Bronze Filament, 2019. https://static1.squarespace.com/static/575b8367b09f95c081a40151/t/5aa7e857f9619a457039385c/1520953431491/TVF+MSDS+Bronze+Filamet%E2%84%A2+18+03-13.pdf. Accessed 20 Oct 2019

ASTM, ASTM D790 03—Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

Phase Diagram of Copper (Cu) and Tin (Sn), 2019. https://www.tf.uni-kiel.de/matwis/amat/iss/kap_6/illustr/i6_2_1.html. Accessed 22 Oct 2019

A.R. TorradoPerez, D.A. Roberson, and R.B. Wicker, Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials, J. Fail. Anal. Prev., 2014, 14, p 343–353

Acknowledgments

This work is partially supported by “Human Resources Program in Energy Technology (No. 20194030202450)”, “Power Generation & Electricity Delivery grant (No. 20181110100310)” of the Korea Institute of Energy Technology Evaluation and Planning (KETEP), and the National Natural Science Foundation of China (No. 51702145).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, Z., Ayeni, O.I., Yang, X. et al. Microstructure and Phase Analysis of 3D-Printed Components Using Bronze Metal Filament. J. of Materi Eng and Perform 29, 1650–1656 (2020). https://doi.org/10.1007/s11665-020-04697-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04697-x