Abstract

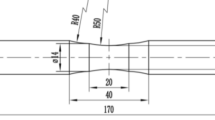

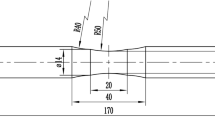

In the present investigation, surface nanostructure was developed on the alloy Ti-6Al-4V using ultrasonic shot peening (USP) and its effect was studied on tensile strength and low-cycle fatigue (LCF) behavior. The gage section of tensile and LCF samples was ultrasonic-shot-peened (USPed) for durations of 2.5, 5.0 and 7.5 min with hard steel shots of 3 mm diameter at constant frequency of 20 kHz using StressVoyager to modify the surface. The yield and tensile strength increased; however, ductility was marginally reduced due to USP. Some of the ultrasonic-shot-peened samples were stress-relieved (SR) at 400 °C for 1 h. LCF tests were conducted on the non-ultrasonic-shot-peened (non-USPed), USPed and USPed + SR samples at different total strain amplitudes (± Δεt/2) of 0.95, 0.85, 0.75 and 0.65% at constant strain rate of 1 × 10−3 s−1. LCF life of the USPed samples was found to be higher than that of the non-USPed sample. LCF life of the USPed specimen at Δεt/2 = ± 0.65% was enhanced by ~ 4 times that of the non-USPed sample. However, the enhanced LCF life of the USPed samples was reduced following stress relieving treatment at 400 °C due to relaxation of the associated compressive stress, though it was still higher than that of the non-USPed sample.

Similar content being viewed by others

References

G.Q. Chen, J. Yan, T.Y. Tian, X.H. Zhang, Z.Q. Li, and W.L. Zhou, Effect of Wet Shot Peening on Ti-6Al-4V Alloy Treated by Ceramic Beads, Trans. Nonferrous Met. Soc. China, 2014, 24, p 690–696

R.R. Boyer, An Overview on the Use of Titanium in the Aerospace Industry, Mater. Sci. Eng. A, 1996, 213, p 103–114

C. Liu, D. Liu, X. Zhang, D. Liu, A. Ma, N. Ao, and X. Xu, Improving Fatigue Performance of Ti-6Al-4V Alloy via Ultrasonic Surface Rolling Process, J Mater Sci. Technol., 2019, 35, p 1555–1562

T. Akahori, M. Niinomi, K. Fukunaga, and I. Inagaki, Effects of Microstructure on the Short Fatigue Crack Initiation and Propagation Characteristics of Biomedical α/β Titanium Alloys, Metal Mater. Trans A, 2000, 31, p 1949–1958

S.R. Thompson, J.J. Ruschau, and T. Nicholas, Influence of Residual Stresses on High Cycle Fatigue Strength of Ti-6Al-4V Subjected to Foreign Object Damage, Int. J Fatigue, 2001, 23, p 405–412

H. Yu, F. Li, Z. Wang, and X. Zeng, Fatigue Performances of Selective Laser Melted Ti-6Al-4V Alloy: Influence of Surface Finishing, Hot Isostatic Pressing and Heat Treatments, Int. J. Fatigue, 2019, 120, p 175–183

J. Li, Y. Yang, Y. Ren, J. Dong, and K. Yang, Effect of Cold Deformation on Corrosion Fatigue Behavior of Nickel-Free High Nitrogen Austenitic Stainless Steel for Coronary Stent Application, J. Mater. Sci. Technol., 2018, 34, p 660–665

Y.G. Liu, M.Q. Li, and H.J. Liu, Nanostructure and Surface Roughness in the Processed Surface Layer of Ti-6Al-4V via Shot Peening, Mater. Character, 2017, 123, p 83–90

M. Thomas and M. Jackson, The Role of Temperature and Alloy Chemistry on Subsurface Deformation Mechanisms During Shot Peening of Titanium Alloys, Scr. Mater., 2012, 66, p 1065–1068

H. Mughrabi, H.W. Hoppel, and M. Kautz, Fatigue and Microstructure of Ultrafine-Grained Metals Produced by Severe Plastic Deformation, Scr. Mater., 2004, 51, p 807–812

X. Li, T.F. Jing, M.M. Lu, R. Xu, B.Y. Liang, and J.W. Zhang, Fatigue Property of Nano-grained Delaminated Low-Carbon Steel Sheet, J. Mater. Sci. Technol., 2011, 27, p 364–368

O. Hatamleh, The Effects of Laser Peening and Shot Peening on Mechanical Properties in Friction Stir Welded 7075-T7351 Aluminum, J. Mater. Eng. Perform., 2008, 17, p 688–694

K. Wu, X. Yuan, Z. Hu, H. Wang, T. Li, Z. Yu, and J. Luo, Improvement of Al/Steel Tungsten Inert Gas Welding-Brazing Joint by High-Energy Shot Peening, J. Mater. Eng. Perform., 2019, 28, p 2937–2945

B.N. Mordyuk and G.I. Prokopenko, Fatigue Life Improvement of Alpha-Titanium by Novel Ultrasonically Assisted Technique, Mater. Sci. Eng. A, 2006, 437, p 396–405

A. Amanov, I.S. Cho, D.E. Kim, and Y.S. Pyun, Fretting Wear and Friction Reduction of CP Titanium and Ti-6Al-4V Alloy by Ultrasonic Nanocrystalline Surface Modification, Surf. Coat. Technol., 2012, 207, p 135–142

L. Xie, Y. Wen, K. Zhan, L. Wang, C. Jiang, and V. Ji, Characterization on Surface Mechanical Properties of Ti-6Al-4V After Shot Peening, J. Alloys Compd., 2016, 666, p 65–70

D. Gallitelli, D. Retraint, and E. Rouhaud, Comparison Between Conventional Shot Peening (SP) and Surface Mechanical Attrition Treatment (SMAT) on a Titanium Alloy, Adv. Mater. Res., 2014, 996, p 964–968

T. Roland, D. Retraint, K. Lu, and J. Lu, Fatigue Life Improvement Through Surface Nanostructuring of Stainless Steel by Means of Surface Mechanical Attrition Treatment, Scr. Mater., 2006, 54, p 1949–1954

Y.K. Gao and X.R. Wu, Experimental Investigation and Fatigue Life Prediction for 7475-T7351 Aluminum Alloy With and Without Shot Peening-Induced Residual Stresses, Acta Mater., 2011, 59, p 3737–3747

F.J. Gil, J.A. Planell, A. Padros, and C. Aparicio, The Effect of Shot Blasting and Heat Treatment on the Fatigue Behavior of Titanium for Dental Implant Applications, Dental Mater., 2007, 23, p 486–491

Y.G. Liu, M.Q. Li, and H.J. Liu, Surface Nanocrystallization and Gradient Structure Developed in the Bulk TC4 Alloy Processed by Shot Peening, J. Alloys Compd., 2016, 685, p 186–193

T. Wang, J. Yu, and B. Dong, Surface Nanocrystallization Induced by Shot Peening and Its Effect on Corrosion Resistance of 1Cr18Ni9Ti Stainless Steel, Surf. Coat. Technol., 2006, 200, p 4777–4781

J.H. Hollomon, Tensile Deformation, Trans. AIME, 1945, 162, p 268–290

G.E. Dieter, Mechanical Metallurgy, McGraw-Hill book Company, Singapore, 1988, p 390–391

G. Liu, J. Lu, and K. Lu, Surface Nanocrystallization of 316L Stainless Steel Induced by Ultrasonic Shot Peening, Mater. Sci. Eng. A, 2000, 286, p 91–95

K.Y. Zhu, A. Vassel, F. Brisset, K. Lu, and J. Lu, Nanostructure Formation Mechanism of α-Titanium Using SMAT, Acta Mater., 2004, 52, p 4101–4110

S. Kumar, K. Chattopadhyay, S.R. Singh, and V. Singh, Surface Nanostructuring of Ti-6Al-4V Alloy Through Ultrasonic Shot Peening, Int. J. Surf. Sci. Eng., 2017, 11, p 23–35

T. Balusamy, T.S.N.S. Narayanan, and K. Ravichandran, Influence of Surface Mechanical Attrition Treatment (SMAT) on the Corrosion Behaviour of AISI, 304 Stainless Steel, Corr. Sci., 2013, 74, p 332–344

Y.W. Zhu, G. Zhang, W.S. Feng, L. Jun, and Y.Z. Feng, Effect of Surface Roughness on Evolution of Residual Stress Field Induced by Shot Peening, Mater. Sci. Technol., 2010, 18, p 523–527

B.X. Feng, X.N. Mao, G.J. Yang, L.L. Yu, and X.D. Wu, Residual Stress field and Thermal Relaxation Behavior of Shot-Peened TC4-DT Titanium Alloy, Mater. Sci. Eng. A, 2009, 512, p 105–108

X.H. Chen, J. Lu, L. Lu, and K. Lu, Tensile Properties of a Nanocrystalline 316L Austenitic Stainless Steel, Scr. Mater., 2005, 52, p 1039–1044

O. Hatamleh, Effects of Peening on Mechanical Properties in Friction Stir Welded 2195 Aluminum Alloy Joints, Mater. Sci. Eng. A, 2008, 492, p 168–176

S. Kumar, G.S. Rao, K. Chattopadhyay, G.S. Mahobia, N.C.S. Srinivas, and V. Singh, Effect of Surface Nanostructure on Tensile Behavior of Superalloy IN718, Mater. Des., 2014, 62, p 76–82

S. Bagherifard and M. Guagliano, Fatigue Behavior of a Low-Alloy Steel with Nanostructured Surface Obtained by Severe Shot Peening, Eng. Fract. Mech., 2012, 81, p 56–68

P.Q. Trung, N.W. Khun, and D.L. Butler, Effect of Shot Peening Process on the Fatigue Life of Shot Peened Low Alloy Steel, J. Eng. Mater. Technol., 2018, 140(208), p 011013

V. Pandey, K. Chattopadhyay, N.C.S. Srinivas, and V. Singh, Role of Ultrasonic Shot Peening on Low Cycle Fatigue Behavior of 7075 Aluminium Alloy, Int. J. Fatigue, 2017, 103, p 426–435

N. Singh and V. Singh, Low Cycle Fatigue Behavior of Ti Alloy IMI, 834 at Room Temperature, Mater. Sci. Eng. A, 2002, 325, p 324–332

Z.F. Zhang, H.C. Gu, and X.L. Tan, Low Cycle Fatigue Behaviors of Commercial-Purity Titanium, Mater. Sci. Eng. A, 1998, 252, p 85–92

J. Zhou, D. Retraint, Z. Sun, and P. Kanoute, Comparative Study of the Effects of Surface Mechanical Attrition Treatment and Conventional Shot Peening on Low Cycle Fatigue of a 316L Stainless Steel, Surf. Coat. Technol., 2018, 349, p 556–566

B. Sahoo, R.K. Satpathy, K. Prasad, S. Ahmed, and V. Kumar, Effect of Shot Peening on Low Cycle Fatigue Life of Compressor Disc of a Typical Fighter Class Aero-Engine, Procedia Eng., 2013, 55, p 144–148

T. Dorr and L. Wagner, Fatigue Response of Various Titanium Alloys to Shot Peening, Trans. Eng. Sci., 1999, 25, p 349–357

Acknowledgments

The authors are grateful to M/s Mishra Dhatu Nigam Limited, Hyderabad (India), for providing the Ti-6Al-4V alloy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Chattopadhyay, K. & Singh, V. Optimization of the Duration of Ultrasonic Shot Peening for Enhancement of Fatigue Life of the Alloy Ti-6Al-4V. J. of Materi Eng and Perform 29, 1214–1224 (2020). https://doi.org/10.1007/s11665-020-04661-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04661-9