Abstract

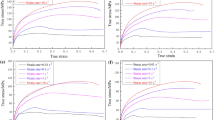

The tensile flow behavior of 17-4PH stainless steel sheet was investigated from 650 °C to 850 °C at strain rates of 10−4 to 10−1 s−1. The result indicates that work hardening and dynamic recovery are exhibited in the tensile test in the temperature lower than 750 °C, and a steady stage of stress occurs higher than 750 °C because of dynamic recrystallization. After a step-by-step procedure for data analysis in the hot tensile test, the original constitutive model was given. Considering the strain compensation, several revised constitutive models of Arrhenius-type were constructed with statistical optimization and multi-strain correction. The comparison shows perfect accurate flow predictions through multi-strain modified models. Meanwhile, the flow behavior of random conditions is predicted accurately by a single correction model with Tikhonov regularization.

Similar content being viewed by others

References

F. Fantechi and M. Innocenti, Chloride Stress Corrosion Cracking of Precipitation Hardening S.S. Impellers in Centrifugal Compressor. Laboratory Investigations and Corrective Actions, Eng. Fail. Anal., 2001, 8(5), p 477–492

M.R.T. Shoushtari, M.H. Moayed, and A. Davoodi, Post-weld Heat Treatment Influence on Galvanic Corrosion of GTAW, Corros. Eng. Sci. Technol., 2011, 46(4), p 415–424

C. Chung and Y. Tzeng, Effects of Aging Treatment on the Precipitation Behavior of ε-Cu Phase and Mechanical Properties of Metal Injection Molding 17-4PH Stainless Steel, Mater. Lett., 2019, 237, p 228–231

F. Stachowicz, T. Trzepiecinski, and T. Pieja, Warm Forming of Stainless Steel Sheet, Arch. Civ. Mech. Eng., 2010, 10(4), p 85–94

T. Trzepiecinski, T. Pieja, T. Malinowski et al., Investigation of 17-4PH Steel Microstructure and Conditions of Elevated Temperature Forming of Turbine Engine Strut, J. Mater. Process. Technol., 2018, 252, p 191–200

T. Trzepiecinski, T. Malinowski, and T. Pieja, Experimental and Numerical Analysis of Industrial Warm Forming of Stainless Steel Sheet, J. Manuf. Process., 2017, 30, p 532–540

M. Aghaie-Khafri, S.H.M. Anijdan, and M. Amirkamali, Microstructural Evolution Under Ausforming and Aging Conditions in 17-4 PH Stainless Steel, Mater. Res. Express, 2019, 6(10), p 10653210. https://doi.org/10.1088/2053-1591/ab37e1

S.A. Razavi, F. Ashrafizadeh, and S. Fooladi, Prediction of Age Hardening Parameters for 17-4PH Stainless Steel by Artificial Neural Network and Genetic Algorithm, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2016, 675, p 147–152

H. Mirzadeh and A. Najafizadeh, Aging Kinetics of 17-4 PH Stainless Steel, Mater. Chem. Phys., 2009, 116(1), p 119–124

J. Wang, H. Zou, C. Li et al., The Effect of Microstructural Evolution on Hardening Behavior of Type 17-4PH Stainless Steel in Long-Term Aging at 350 °C, Mater. Charact., 2006, 57(4–5), p 274–280

H.J. Mcqueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2002, 322(1), p 43–63

W. Lee and C. Liu, The Effects of Temperature and Strain Rate on the Dynamic Flow Behaviour of Different Steels, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2006, 426(1–2), p 101–113

M. Zhou, Y.C. Lin, J. Deng et al., Hot Tensile Deformation Behaviors and Constitutive Model of an Al–Zn–Mg–Cu Alloy, Mater. Des., 2014, 59, p 141–150

D. Samantaray, S. Mandal, A.K. Bhaduri et al., Analysis and Mathematical Modelling of Elevated Temperature Flow Behaviour of Austenitic Stainless Steels, Mater. Sci. Eng. A, 2011, 528(4), p 1937–1943

B. Mcdonald, H. Bornstein, A. Ameri et al., Plasticity and Ductile Fracture Behaviour of Four Armour Steels, Int. J. Solids Struct., 2019, 176–177, p 135–149

D.M. Umbrello, R. Saoubi, and J.C. Outeiro, The Influence of Johnson–Cook Material Constants on Finite Element Simulation of Machining of AISI, 316L Steel, Int. J. Mach. Tools Manuf., 2007, 47(3), p 462–470

N. Haghdadi, A. Zarei-Hanzaki, and H.R. Abedi, The Flow Behavior Modeling of Cast A356 Aluminum Alloy at Elevated Temperatures Considering the Effect of Strain, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2012, 535, p 252–257

N. Kotkunde, H.N. Krishnamurthy, P. Puranik et al., Microstructure Study and Constitutive Modeling of Ti–6Al–4V Alloy at Elevated Temperatures, Mater. Des. (1980–2015), 2014, 54, p 96–103

D. Samantaray, S. Mandal, and A.K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli–Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr-1Mo Steel, Comput. Mater. Sci., 2009, 47(2), p 568–576

H. Li, Y. Li, X. Wang et al., A Comparative Study on Modified Johnson Cook, Modified Zerilli–Armstrong and Arrhenius-Type Constitutive Models to Predict the Hot Deformation Behavior in 28CrMnMoV Steel, Mater. Des., 2013, 49, p 493–501

Y.C. Lin and X. Chen, A Combined Johnson-Cook and Zerilli-Armstrong Model for Hot Compressed Typical High-Strength Alloy Steel, Comput. Mater. Sci., 2010, 49(3), p 628–633

A.S. Khan and R.Q. Liang, Behaviors of Three BCC Metal Over a Wide Range of Strain Rates and Temperatures: Experiments and Modeling, Int. J. Plast., 1999, 15(10), p 1089–1109

S. Dey, T. Borvik, O.S. Hopperstad et al., On the Influence of Constitutive Relation in Projectile Impact of Steel Plates, Int. J. Impact Eng., 2007, 34(3), p 464–486

A.M. Lennon and K.T. Ramesh, The Influence of Crystal Structure on the Dynamic Behavior of Materials at High Temperatures, Int. J. Plast., 2004, 20(2), p 269–290

A.K. Gupta, V.K. Anirudh, and S.K. Singh, Constitutive Models to Predict Flow Stress in Austenitic Stainless Steel 316 at Elevated Temperatures, Mater. Des., 2013, 43, p 410–418

W. Wang, J. Zhao, R.X. Zhai, R. Ma, Arrhenius-Type Constitutive Model and Dynamic Recrystallization Behavior of 20Cr2Ni4A Alloy Carburizing Steel, Steel Res. Int., 2017, 88(3), p 1600196. https://doi.org/10.1002/srin.201600196

L. Wang, F. Liu, J.J. Cheng et al., Arrhenius-Type Constitutive Model for High Temperature Flow Stress in a Nickel-Based Corrosion-Resistant Alloy, J. Mater. Eng. Perform., 2016, 25(4), p 1394–1406

A. Cingara and H.J. Mcqueen, New Formula for Calculating Flow Curves from High Temperature Constitutive Data for 300 Austenitic Steels, J. Mater. Process. Technol., 1992, 36(1), p 31–42

H. Li, L. He, G. Zhao et al., Constitutive Relationships of Hot Stamping Boron Steel B1500HS Based on the Modified Arrhenius and Johnson–Cook Model, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2013, 580, p 330–348

X. Guo, X. Weng, Y. Jiang et al., Effects of Temperature and Strain Rate on Tensile Deformation Behavior of 9Cr-0.5Mo-1.8W-VNb Ferritic Heat-Resistant Steel, High Temp. Mater. Process., 2017, 36(9), p 913–920

S.A. Krishnan, C. Phaniraj, C. Ravishankar et al., Prediction of High Temperature Flow Stress in 9Cr-1Mo Ferritic Steel During Hot Compression, Int. J. Press. Vessels Pip., 2011, 88(11–12), p 501–506

Y.C. Lin, M. Chen, and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comput. Mater. Sci., 2008, 42(3), p 470–477

S. Mandal, V. Rakesh, P.V. Sivaprasad et al., Constitutive Equations to Predict High Temperature Flow Stress in a Ti-Modified Austenitic Stainless Steel, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2009, 500(1–2), p 114–121

H. Mirzadeh, A. Najafizadeh, and M. Moazeny, Flow Curve Analysis of 17-4PH Stainless Steel under Hot Compression Test, Metall. Mater. Trans. A, 2009, 40(12), p 2950–2958

H. Mirzadeh, A Simplified Approach for Developing Constitutive Equations for Modeling and Prediction of Hot Deformation Flow Stress, Metall. Mater. Trans. A, 2015, 46(9), p 4027–4037

C.M. Sellars and W.J. Mctegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14(9), p 1136–1138

Y. Cao, H. Di, R.D.K. Misra et al., On the Hot Deformation Behavior of AISI, 420 Stainless Steel Based on Constitutive Analysis and CSL Model, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2014, 593, p 111–119

A. Mirzaei, A. Zarei-Hanzaki, N. Haghdadi et al., Constitutive Description of High Temperature Flow Behavior of Sanicro-28 Super-Austenitic Stainless Steel, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2014, 589, p 76–82

E. Pu, H. Feng, M. Liu et al., Constitutive Modeling for Flow Behaviors of Superaustenitic Stainless Steel 532654 during Hot Deformation, J. Iron Steel Res. Int., 2016, 23(2), p 178–184

Y.Q. Jiang, Y.C. Lin, X.-Y. Zhang et al., Isothermal Tensile Deformation Behaviors and Fracture Mechanism of Ti-5Al-5Mo-5V-1Cr-1Fe Alloy in β Phase Field, Vacuum, 2018, 156, p 187–197

Y.C. Lin, H. Yang, Y. Xin et al., Effects of Initial Microstructures on Serrated Flow Features and Fracture Mechanisms of a Nickel-Based Superalloy, Mater. Charact., 2018, 144, p 9–21

Y. Wang, K. Song, Y. Zhang et al., Microstructure Evolution and Fracture Mechanism of H13 Steel During High Temperature Tensile Deformation, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2019, 746, p 127–133

F.A. Slooff, J. Zhou, J. Duszczyk et al., Constitutive Analysis of Wrought Magnesium Alloy Mg–Al4–Zn1, Scr. Mater., 2007, 57(8), p 759–762

P.C. Hansen, Regularization Tools: A Matlab Package for Analysis and Solution of Discrete Ill-Posed Problems, Numer. Algorithms, 1994, 6(1), p 1–35

Acknowledgments

The authors gratefully acknowledge the support from Aeronautical Science Foundation of China (20153021001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Su, N., Chen, M., Zhang, W. et al. Constitutive Modeling of 17-4PH Stainless Steel Sheet at Elevated Temperature and Statistical Optimization. J. of Materi Eng and Perform 29, 1194–1205 (2020). https://doi.org/10.1007/s11665-020-04648-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04648-6