Abstract

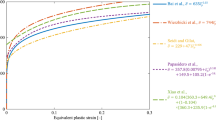

Two mainstreams of transformation methods from isotropic fracture criteria to anisotropic ones are to replace the Von Mises yield function with other yield function and linear transformation of strain or stress tensor. Several typical anisotropic criteria such as the transformation methods of Park, Luo, Lou and Yoon, Jia and Bai and a new transformation method are analyzed and discussed from the aspects of required experimental data, material constant amounts, stress state range, average predictive error (Erravg), etc. The fitting results demonstrate that the prediction accuracy of the methods of Luo, Lou and Yoon, Jia and Bai and the new method are better than that of the isotropic criteria from the Erravg aspect based on the experimental results of DP590. In addition, the new transformation method linearly transforms both stress and strain tensor without increasing too many parameters.

Similar content being viewed by others

References

A.L. Gurson, Continuum Theory of Ductile Rupture by Void Nucleation and Growth: Part I—Yield Criteria and Flow Rules for Porous Ductile Media, J. Eng. Mater. Technol., 1977, 99, p 2–15

V. Tvergaard, Influence of Void Nucleation on Ductile Shear Fracture at a Free Surface, J. Mech. Phys. Solids, 1982, 30, p 399–425

V. Tvergaard and A. Needleman, Analysis of the Cup-Cone Fracture in a Round Tensile Bar, Acta Metall., 1984, 32, p 157–169

K. Nahshon and J. Hutchinson, Modification of the Gurson Model for Shear Failure, Eur. J. Mech. A Solids, 2008, 27, p 1–17

K.L. Nielsen and V. Tvergaard, Ductile Shear Failure or Plug Failure of Spot Welds Modelled by Modified Gurson Model, Eng. Fract. Mech., 2010, 77, p 1031–1047

Z. Xue, J. Faleskog, and J.W. Hutchinson, Tension–Torsion Fracture Experiments–Part II: Simulations with the Extended Gurson Model and a Ductile Fracture Criterion Based on Plastic Strain, Int. J. Solids Struct., 2013, 50, p 4258–4269

J. Lemaitre, A Continuous Damage Mechanics Model for Ductile Fracture, J. Eng. Mater. Technol., 1985, 107, p 83–89

L.M. Kachanov, Time of the Rupture Process under Creep Conditions, Izy Akad, Nank SSR Otd Tech Nauk, 1958, 8, p 26–31

J.L. Chaboche, M. Boudifa, and K. Saanouni, A CDM Approach of Ductile Damage with Plastic Compressibility, Int. J. Fract., 2006, 137, p 51–75

L. Malcher and E. Mamiya, An Improved Damage Evolution Law Based on Continuum Damage Mechanics and Its Dependence on Both Stress Triaxiality and the Third Invariant, Int. J. Plast., 2014, 56, p 232–261

M. Cockcroft and D. Latham, Ductility and the Workability of Metals, J. Inst. Metals, 1968, 96, p 33–39

F.A. McClintock, A Criterion for Ductile Fracture by the Growth of Holes, J. Appl. Mech., 1968, 35, p 363–371

J.R. Rice and D.M. Tracey, On the Ductile Enlargement of Voids in Triaxial Stress Fields, J. Mech. Phys. Solids, 1969, 17, p 201–217

P. Brozzo, B. Deluca, and R. Rendina, A New Method for the Prediction of Formability in Metal Sheets, Sheet Material Forming and Formability. In: Proceedings of the Seventh Biennial Conference of the IDDRG (1972)

S. Oh, C. Chen, and S. Kobayashi, Ductile Fracture in Axisymmetric Extrusion and Drawing—Part 2: Workability in Extrusion and Drawing, J. Eng. Ind., 1979, 101, p 36–44

M. Oyane, T. Sato, K. Okimoto, and S. Shima, Criteria for Ductile Fracture and Their Applications, J. Mech. Working Technol., 1980, 4, p 65–81

S.E. Clift, P. Hartley, C. Sturgess, and G. Rowe, Fracture Prediction in Plastic Deformation Processes, Int. J. Mech. Sci., 1990, 32, p 1–17

Y.K. Ko, J.S. Lee, H. Huh, H.K. Kim, and S.H. Park, Prediction of Fracture in Hub-Hole Expanding Process Using a New Ductile Fracture Criterion, J. Mater. Process. Technol., 2007, 187, p 358–362

Y.L. Bai and T. Wierzbicki, Application of Extended Mohr–Coulomb Criterion to Ductile Fracture, Int. J. Fract., 2010, 161, p 1–20

Y. Lou, H. Huh, S. Lim, and K. Pack, New Ductile Fracture Criterion for Prediction of Fracture Forming Limit Diagrams of Sheet Metals, Int. J. Solids Struct., 2012, 49, p 3605–3615

Y.S. Lou, J.W. Yoon, and H. Huh, Modeling of Shear Ductile Fracture Considering a Changeable Cut-off Value for Stress Triaxiality, Int. J. Plast., 2014, 54, p 56–80

Y.S. Lou, L. Chen, T. Clausmeyer, A.E. Tekkaya, and J.W. Yoon, Modeling of Ductile Fracture From Shear to Balanced Biaxial Tension for Sheet Metals, Int. J. Solids Struct., 2017, 112, p 169–184

Y. Lou and H. Huh, Evaluation of Ductile Fracture Criteria in a General Three-Dimensional Stress State Considering the Stress Triaxiality and the Lode Parameter, Acta Mech. Solida Sin., 2013, 26, p 642–658

Q. Hu, F.F. Zhang, X.F. Li, and J. Chen, Overview on the Prediction Models for Sheet Metal Forming Failure: Necking and Ductile Fracture, Acta Mech. Solida Sin., 2018, 31, p 259–289

O.S. Es-Said, C.J. Parrish, C.A. Bradberry, J.Y. Hassoun, R.A. Parish, A. Nash, N.C. Smythe, K.N. Tran, T. Ruperto, E.W. Lee, D. Mitchell, and C. Vinquist, Effect of Stretch Orientation and Rolling Orientation on the Mechanical Properties of 2195 Al-Cu-Li Alloy, J. Mater. Eng. Perform., 2011, 20, p 1171–1179

M. Masoumi, M.A. Mohtadi-Bonab, and H.F.G. de Abreu, Effect of Microstructure and Texture on Anisotropy and Mechanical Properties of SAE 970X Steel Under Hot Rolling, J. Mater. Eng. Perform., 2016, 25, p 2847–2854

M. Grange, J. Besson, and E. Andrieu, An Anisotropic Gurson Type Model to Represent the Ductile Rupture of Hydrided Zircaloy-4 Sheets, Int. J. Fract., 2000, 105, p 273–293

Z. Chen and X. Dong, The GTN Damage Model based on Hill’48 Anisotropic Yield Criterion and Its Application in Sheet Metal Forming, Comput. Mater. Sci., 2009, 44, p 1013–1021

A.S. Khan and H.W. Liu, Strain Rate and Temperature Dependent Fracture Criteria for Isotropic and Anisotropic Metals, Int. J. Plast., 2012, 37, p 1–15

M. Luo, M. Dunand, and D. Mohr, Experiments and Modeling of Anisotropic Aluminum Extrusions Under Multi-axial Loading—Part II: Ductile Fracture, Int. J. Plast., 2012, 32–33, p 36–58

G.Y. Gu and D. Mohr, Anisotropic Hosford–Coulomb fracture Initiation Model: Theory and Application, Eng. Fract. Mech., 2015, 147, p 480–497

N. Park, H. Huh, and J.W. Yoon, Anisotropic Fracture Forming Limit Diagram Considering Non-directionality of the Equi-biaxial Fracture Strain, Int. J. Solids Struct., 2018, 151, p 181–194

L. Dong, S.H. Li, and J. He, Ductile Fracture Initiation of Anisotropic Metal Sheets, J. Mater. Eng. Perform., 2017, 26, p 3285–3298

Y.L. Bai and T. Wierzbicki, A Comparative Study of Three Groups of Ductile Fracture Loci in the 3D Space, Eng. Fract. Mech., 2015, 135, p 147–167

L. Xue, Damage Accumulation and Fracture Initiation in Uncracked Ductile Solids Subject to Triaxial Loading, Int. J. Solids Struct., 2007, 44, p 5163–5181

A.K. Ghosh, A Criterion for Ductile Fracture in Sheets Under Biaxial Loading, Metall. Trans. A, 1976, 7, p 523–533

Y. Lou and H. Huh, Extension of a Shear-Controlled Ductile Fracture Model Considering the Stress Triaxiality and the Lode Parameter, Int. J. Solids Struct., 2013, 50, p 447–455

Q. Hu, X.F. Li, X.H. Han, and J. Chen, A New Shear and Tension Based Ductile Fracture Criterion: Modeling and Validation, Eur. J. Mech. A-Solids, 2017, 66, p 370–386

Y. Bao and T. Wierzbicki, On the Cut-off Value of Negative Triaxiality for Fracture, Eng. Fract. Mech., 2005, 72, p 1049–1069

A.S. Khan and H.W. Liu, A New Approach for Ductile Fracture Prediction on Al 2024-T351 Alloy, Int. J. Plast., 2012, 35, p 1–12

N. Park, H. Huh, S.J. Lim, Y.S. Lou, Y.S. Kang, and M.H. Seo, Fracture-Based Forming Limit Criteria for Anisotropic Materials in Sheet Metal Forming, Int. J. Plast., 2017, 96, p 1–35

N. Park, H. Huh, J. Nam, and C. Jung, Anisotropy Effect On The Fracture Model of DP980 Sheets Considering the Loading Path, Int. J. Automot. Technol., 2015, 16, p 73–81

Y.S. Lou and J.W. Yoon, Alternative Approach to Model Ductile Fracture by Incorporating Anisotropic Yield Function, Int. J. Solids Struct., 2019, 164, p 12–24

A.M. Beese, M. Luo, Y.N. Li, Y.L. Bai, and T. Wierzbicki, Partially Coupled Anisotropic Fracture Model for Aluminum Sheets, Eng. Fract. Mech., 2010, 77, p 1128–1152

T. Kuwabara, A. Van Bael, and E. Iizuka, Measurement and Analysis of Yield Locus and Work Hardening Characteristics of Steel Sheets with Different r-Values, Acta Mater., 2002, 50, p 3717–3729

R. Pearce, Some Aspects of Anisotropic Plasticity in Sheet Metals, Int. J. Mech. Sci., 1968, 10, p 995–1004

Y.S. Lou and J.W. Yoon, Anisotropic Yield Function Based on Stress Invariants for BCC and FCC Metals and Its Extension to Ductile Fracture Criterion, Int. J. Plast., 2018, 101, p 125–155

S.H. Li, J. He, B. Gu, D. Zeng, Z.C. Xia, Y.X. Zhao, and Z.Q. Lin, Anisotropic Fracture of Advanced High Strength Steel Sheets: Experiment and Theory, Int. J. Plast., 2018, 103, p 95–118

Y.S. Lou and J.W. Yoon, Anisotropic Ductile Fracture Criterion Based on Linear Transformation, Int. J. Plast., 2017, 93, p 3–25

F. Barlat, K. Chung, and O. Richmond, Strain Rate Potential for Metals and Its Application to Minimum Plastic Work Path Calculations, Int. J. Plast., 1993, 9, p 51–63

F. Barlat, H. Aretz, J.W. Yoon, M.E. Karabin, J.C. Brem, and R.E. Dick, Linear Transformation-Based Anisotropic Yield Functions, Int. J. Plast., 2005, 21, p 1009–1039

Y.Q. Jia and Y.L. Bai, Ductile Fracture Prediction for Metal Sheets Using All-Strain-Based Anisotropic eMMC Model, Int. J. Mech. Sci., 2016, 115, p 516–531

Y.Q. Jia and Y.L. Bai, Experimental Study on the Mechanical Properties of AZ31B-H24 Magnesium Alloy Sheets Under Various Loading Conditions, Int. J. Fract., 2016, 197, p 25–48

W. Hosford, A Generalized Isotropic Yield Criterion, J. Appl. Mech., 1972, 39, p 607–609

A. Hershey, The Plasticity of an Isotropic Aggregate of Anisotropic Face-Centered Cubic Crystals, J. Appl. Mech. Trans. ASME, 1954, 21, p 241–249

F. Barlat, D.J. Lege, and J.C. Brem, A Six-Component Yield Function for Anisotropic Materials, Int. J. Plast., 1991, 7, p 693–712

Acknowledgments

The authors are grateful for the financial support from The Ministry of Science and Technology of China through the National Key Research and Development Project with Grant # 2017YFB0304403.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Rodrigues’ Rotation Formula

The strain tensor can be expressed by three principal strains according to the coordinate system along rolling direction, transverse direction and normal direction (RD, TD and ND) as shown in Eq 41.

where \(t = 1 - \cos \theta\), \(c = \cos \theta\), \(s = \sin \theta\), \(\hat{u} = x\hat{i} + y\hat{j} + z\hat{k}\). \(\hat{u}\) and θ denote a unit vector for a rotation axis and the rotation angle, respectively. For the application of the fracture surface to sheet metal forming, the unit vector of a rotation axis can be defined as \(\hat{u} = x\hat{i} + y\hat{j} + z\hat{k} = \hat{k}\). Therefore, Eq 41 can be simplified to Eq 42.

Appendix 2: A Definition of the Strain Rate Potential for Plastically Deforming Metals

Due to the incompressibility during the plastic deformation, Barlat et al. (Ref 50) redefined the strain rate potential ψ based on the work-equivalent effective strain obtained by the TBH model.

Accordingly, the equivalent plastic strain can be expressed as follows:

Based on the procedure of transforming the isotropic yield function (Ref 54, 55) into the anisotropic yield function (Ref 56), the anisotropic equivalent plastic strain rate with six plastic strain rate components in the axes of orthotropic symmetry x, y and z is shown as follows.

The six material constants of βi (i = 1,2,3,4,5,6) indicate the anisotropy of alloys. The eigenvalues of \(\dot{\varvec{\varepsilon }}_{\varvec{d}}\) including \(\varepsilon_{1}^{d}\), \(\varepsilon_{2}^{d}\) and \(\varepsilon_{3}^{d}\) can be obtained by solving the eigenfunction.

where

The expressions of eigenvalues of \(\dot{\varvec{\varepsilon }}_{\varvec{d}}\) are shown as follows:

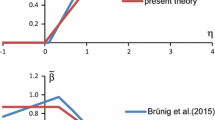

\(\dot{\varvec{\varepsilon }}_{\varvec{d}}\) is reduced to \(\dot{\varvec{\varepsilon }}_{\varvec{p}}\) if all the material constants are equal to 1. Therefore, above method induces a new method for explicitly expressing the principal strain by strain components. Moreover, the expression of \(\dot{\varvec{\varepsilon }}_{\varvec{d}}\) meets the constant-volume principle in the metal forming processes regardless of the anisotropic constant values. The transformation method of Lou and Yoon involves the anisotropy. However, it is not based on the constant-volume principle in the process of introducing anisotropic parameters.

Appendix 3: Explicit Function of the Principal Strain Through Strain Components

The process of calculating the principal strain according to strain components is similar to that of getting eigenvalues of the third-order square matrix. Next, the general process of obtaining them is introduced.

The corresponding eigenfunction is shown in Eq 51.

where the coefficients are listed as follows:

Let

Equation 51 is simplified to Eq 54 as follows:

where the coefficients are listed as follows:

The calculating results are shown as follows:

where ω1 and ω2 are expressed in Eq 57.

Eigenvalues of the third-order square matrix are revealed as below:

According to the above method of the strain, the principal strain is shown as follows.

The corresponding eigenfunction is shown in Eq 60:

where the coefficients are listed as follows:

Because εp is a symmetric matrix and εyz = εzx = 0 under plane stress conditions, Eq 61 can be simplified to Eq 62.

Let

The three principal strains are expressed as follows:

The above method is used to the transformation method of Lou and Yoon. According to Eq 25, the equations of M and N are shown as follows.

Rights and permissions

About this article

Cite this article

Ju, K., Zhu, F., Li, X. et al. Development of Uncoupled Anisotropic Ductile Fracture Criteria. J. of Materi Eng and Perform 29, 1282–1295 (2020). https://doi.org/10.1007/s11665-020-04592-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04592-5