Abstract

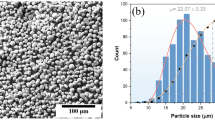

The structure and mechanical properties of steel AISI 1045 subjected to three passes of the combined process “helical rolling–pressing” at a temperature of 500 °C were investigated. During the helical rolling–pressing process, the structure was substantially crushed to ultrafine-grained state, as the structure of steel AISI 1045 with an average grain size of 25 µm after deformation was decreased by 25 times, the average grain size was 1 µm. The values of tensile strength and yield strength increase in three passes from 619 to 925 MPa and from 545 to 867 MPa, respectively. The relative contraction after rupture varies from 42 to 35%; but the change is not as significant as in usual helical rolling. The combined helical rolling–pressing process is an effective way to form an ultrafine-grained structure and improve the mechanical properties of AISI 1045 steel.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater Sci., 2000, 45, p 103–189

G.I. Raab, A.G. Raab, R.N. Asfandiyarov, E.I. Fakhretdinova, Combined and Consecutive SPD Processing Techniques, Machines. Technologies. Materials. Proceedings, Volume III « MATERIALS » , pp. 187–188 (2017)

X. Zhao, N. Chen, and N. Zhao, Numerical Simulation of Equal Channel Angular Pressing for Multi-Pass in Different Routes, Appl. Mech. Mater., 2012, 268–270, p 373–377

I.E. Volokitina and G.G. Kurapov, Effect of Initial Structural State on Formation of Structure and Mechanical Properties of Steels Under ECAP, Met. Sci. Heat Treat., 2018, 59, p 786–792

S. Wang, W. Liang, Yu Wang, L. Bian, and K. Chen, A Modified Die for Equal Channel Angular Pressing, J. Mater. Process. Technol., 2009, 209, p 3182–3186

A.B. Nayzabekov and I.E. Volokitina, Effect of the Initial Structural State of Cr–Mo High-Temperature Steel on Mechanical Properties after Equal-Channel Angular Pressing, Phys. Met. Metall., 2019, 120(2), p 177–183

G. Raab, R. Valiev, T. Lowe, and Y. Zhu, Continuous Processing of Ultrafine Grained A1 by ECAP-Conform, Mater. Sci. Eng., 2004, 382, p 30–34

G.I. Raab, E.I. Fakhretdinova, R.Z. Valiev, L.P. Trifonenkov, and V.F. Frolov, Computer Study of the Effect of Tooling Geometry on Deformation Parameters in the Plastic Shaping of Aluminum Wire Rod by Multi-ECAP-Conform, Metallurgist, 2016, 59(11–12), p 1007–1014

M. Vaseghi, H.S. Kim, A.K. Taheri, and A. Momeni, Inhomogeneity Through Warm Equal Channel Angular Pressing, J. Mater. Eng. Perform., 2013, 22(6), p 1666–1671

A. Naizabekov, A. Arbuz, S. Lezhnev, E. Panin, and I. Volokitina, The Development and Testing of a New Method of Qualitative Analysis of the Microstructure Quality, for Ex-ample of Steel AISI, 321 Subjected to Radial Shear Rolling, Physica Scripta, 2019, 1, p 94. https://doi.org/10.1088/1402-4896/ab1e6e

A. Korbel and W. Bochniak, Refinement and Control of the Metal Structure Elements by Plastic Deformation, Scripta Mater., 2004, 51, p 755

Y.G. Jin, I.H. Son, S.H. Kang, and Y.T. Im, Three-Dimensional Finite Element Analysis of Multi-Pass Equal-Channel Angular Extrusion of Aluminum AA1050 with Split Dies, Mater. Sci. Eng., 2009, 503, p 152

A. Naizabekov, I. Volokitina, A. Volokitin, and E. Panin, Structure and Mechanical Properties of Steel in the Process “Pressing–Drawing”, J. Mater. Eng. Perform., 2019, 28(3), p 1762–1771

S.K. Hwanga, H.M. Baeka, I.H. Sonb, Y.T. Ima, and C.M. Baeb, Mater. Sci. Eng. A, 2013, 579, p 118

J.W. Leea, H.M. Baeka, S.K. Hwanga, I.H. Sonb, C.I. Baeb, and Y.T. Ima, Mater. Des., 2014, 55, p 898

L.S. Derevyagina, A.I. Gordienko, YuI, Pochivalov, and A.S. Smirnova, Modification of the Structure of Low-Carbon Pipe Steel by Helical Rolling, and the Increase in Its Strength and Cold Resistance, Phys. Metals Metallogr., 2018, 119, p 83–91

K.V. Ivanov, E.V. Naydenkin, O.N. Lykova, I.V. Ratochka, I.P. Mishin, and V.A. Vinokurov, Structure Evolution and Mechanical Properties of a Ti-6Al-4 V Alloy During Helical Rolling and Subsequent Deformation and Heat Treatments, Russ. Phys. J., 2017, 60, p 1226–1232

Patent of the Republic Of Kazakhstan № 25863. Device for Continuous Metal Pressing/A.B. Naizabekov, S.N. Lezhnev, E.A. Panin;. – 2013. Bull. No. 7

S. Lezhnev, A.B. Naizabekov, E. Panin, I. Volokitina, and T. Koinov, The Effect of Preliminary and Final Heat Treatment in Course of the Combined “Rolling-Pressing” Process Realization on Microstructure Evolution of Copper, J. Chem. Technol. Metall., 2016, 51, p 315–321

A. Naizabekov, S. Lezhnev, E. Panin, I. Volokitina, A. Arbuz, T. Koinov, and I. Mazur, Effect of Combined Rolling–ECAP on Ultrafine-Grained Structure and Properties in 6063 Al Alloy, J. Mater. Eng. Perform., 2019, 28(1), p 200–210

Patent of Russian Federation № 2347631. Method of Producing Blanks with Fine-Grained Structure by Combined Helical and Longitudinal Rolling/R.Z. Valiev, H.S. Salimgareev, R.R. Valiev; 2009

A. Naizabekov, V. Talmazan, A. Arbuz, T. Koinov, and S. Lezhnev, Study of Axial Forces with the Purpose to Realize A Combined Process « Helical Rolling-Pressing», J. Chem. Technol. Metall., 2015, 50, p 217–222

A. Naizabekov, S. Lezhnev, A. Arbuz, and E. Panin, Combined Process “Helical Rolling-Pressing” and its Effect on the Microstructure of Ferrous and Non-Ferrous Materials, Metall. Res. Technol., 2018, 115, p 213

Patent of Russian Federation № 2293619. Method of Helical Rolling/Galkin S.P.; 2007. Bull. № 5

S. Lezhnev, A. Naizabekov, and I. Volokitina, Features of Change of the Structure and Mechanical Properties of Steel at Ecap Depending on the Initial State, J. Chem. Technol. Metall., 2017, 52(4), p 626–635

H. Yada, N. Matsuzu, K. Nakajima, K. Watanabe, and H. Tokita, Strength and Structural-Changes Under High Strain-Rate Hot Deformation of C-Steels, Trans. ISIJ, 1983, 23, p 100–109

Пaт. № 2293619 Poccийcкaя Фeдepaция, MПК B21B 19/00. Cпocoб винтoвoй пpoкaтки/Гaлкин C. П.; зaявитeль и пaтeнтooблaдaтeль HИTУ MИCиcyнoк – № 2006110612/02, зaявл. 04.04.2006; oпyбл. 20.02.2007. Бюл. изoбp., 2007, № 5

E.A. Panin, A.B. Naizabekov, S.N. Lezhnev, Simulation of the Joint ‘Rolling-Pressing’ Process Using Equal-Channel Step Die. in 17-th International Conference on Metallurgy and Materials METAL-2008, Ostrava, Czech Republic, 2008.

L.S. Derevyagina, A.I. Gordienko, YuI, Pochivalov, and A.S. Smirnova, Modification of the Structure of Low-Carbon Pipe Steel by Helical Rolling, and the Increase in Its Strength and Cold Resistance, Phys. Met. Metall., 2018, 119(1), p 83–91

A.A. Bogatov and E.I. Panov, Effect of Stress-Strain State During Helical Rolling on Metal and Alloy Structure and Ductility, Metallurgist, 2013, 57(5–6), p 434–441

M. Samaee, S. Najafi, A.R. Eivani, and H.R.J. Jafarian, Zhou Simultaneous Improvements of the Strength and Ductility of Fine-Grained AA6063 Alloy with Increasing Number of ECAP Passes, Mater. Sci. Eng. A, 2016, 669, p 350–357

M. Kawasaki, Z. Horita, and T.G. Langdon, Microstructural Evolution in High Purity Aluminum Processed by ECAP, Mater. Sci. Eng. A, 2009, 524(1–2), p 143–150

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Naizabekov, A., Volokitina, I., Lezhnev, S. et al. Structure and Mechanical Properties of AISI1045 in the Helical Rolling–Pressing Process. J. of Materi Eng and Perform 29, 315–329 (2020). https://doi.org/10.1007/s11665-019-04536-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04536-8