Abstract

55Ni-17Cr-12Fe-9Mo-2Nb-1.5Al alloy is a nickel-based superalloy (Russian designation is XH55MбЮ or KhN55MBYu, XH55) without any equivalent in American/European alloy designation. It is used in cryogenic engine of satellite launch vehicles application in two different heat-treated conditions: (1) standard aged (STA) at 730 °C/15 h + 650 °C/10 h and (2) STA + BC (brazing cycle) treatment carried out in vacuum at 1030 °C with holding time of 30 min. Due to the braze cycle adopted for manufacturing, it is essential to study the deterioration in mechanical properties, if any. Hence, the present work is carried out to understand the material behavior in tensile mode (25, 425, 575, 700 and 900 °C) for XH55 alloy in STA condition and STA + BC conditions, compared with corresponding microstructural analysis, morphology and composition using microscopy at various length scales. The tensile stress–strain curve shows characteristic sudden drops in stress with respect to strain, attributed to dynamic strain aging at different temperatures for both STA and STA + BC conditions. In STA condition, the yield strength of the material decreased with increase in temperature. In STA + BC condition, the yield strength decreased up to 425 °C, increased up to 700 °C as the material was subjected to artificial aging during testing and finally decreased at 900 °C. Marginal deterioration in mechanical properties have been observed due to the braze cycle adopted against STA condition.

Similar content being viewed by others

References

M. Pender, INCONEL Alloy 706, Electric Power Research Institute, Charlotte, NC, 2007. http://citeseerx.ist.psu.edu/viewdoc/download?rep=rep1&type=pdf&doi=10.1.1.205.6864

S.N. Rosenwasser, and W.R. Johnson, Gas-Turbine HTGR Materials Screening Test Program, General Atomic Project 3227, GA-A14122, UC-77, USA, Sept 30, 1976, p 15

J.R. Davis, Ed., ASM Specialty Handbook: Heat-Resistant Materials, ASM International, Cleveland, 1997

F.A.Harf, Properties and Microstructures for Dual Alloy Combinations of Three Superalloys with Alloy 901, NASA-TM-86987, 1985. https://www.osti.gov/biblio/5090312

R.E. Schafrik, D.D. Ward, and J.R. Groh, Application of Alloy 718 in GE Aircraft Engines: Past, Present and Next Five Years, Superalloys 718, 625, 706 and Various Derivatives, The Minerals, Metals & Materials Society, 2001, p 1–11. https://doi.org/10.7449/2001/superalloys_2001_1_11

Haynes 25 Alloy, Haynes International Brochure H-3057G, USA. http://haynesintl.com/docs/default-source/pdfs/new-alloy-brochures/high-temperature-alloys/brochures/25-brochure.pdf?sfvrsn=26

K.J. Ducki, Analysis of the Precipitation and Growth Processes of the Intermetallic Phases in an Fe-Ni Superalloy, InTech open science, 2015, p 111–137. https://doi.org/10.5772/61159

B. Max, B. Viguier, E. Andrieu, and J. Marc Cloue, A Re-examination of the Portevin-Le Chatelier Effect in Alloy 718 in Connection with Oxidation-Assisted Intergranular Cracking, Metall. Mater. Trans. A, 2014, 45, p 5431–5441. https://doi.org/10.1007/s11661-014-2508-6

G.M. Sayeed Ahmeda, M.V. Mohiuddin, H. Salma Sultana, V. Krishnamurthy Dora, and D. Singh, Microstructure Analysis and Evaluation of Mechanical Properties of Nickel Based Super Alloy CCA617, Mater. Today Proc., 2015, 2, p 1260–1269. https://doi.org/10.1016/j.matpr.2015.07.041

A.D. Ivanov, S.B. Nikitina, and A.G. Ukhlinov, Phase Transformations in Alloys of the Ni-Cr-Fe-Mo-Nb-Al-Ti System, Met. Sci. Heat Treat., 1993, 35(5), p 290–293. https://doi.org/10.1007/BF00780599

V.I. Tkachov, L.M. Ivas’kevych, and O.M. Voznychak, Effect of Hydrogen on the Mechanical Properties of Welded Joints of 03Kh12N10MT Steel and KhN55MBYu Alloy, Mater. Sci., 2004, 40(6), p 772–780. https://doi.org/10.1007/s11003-005-0114-x

K. Gopinath, A.K. Gogia, S.V. Kamat, and U. Ramamurty, Dynamic Strain Ageing in Ni-Base Superalloy 720Li, Acta Mater., 2009, 57, p 1243–1253. https://doi.org/10.1016/j.actamat.2008.11.005

C. Marsh and D. Kaoumi, Serrated Tensile Flow in Inconel X750 Sheets: Effect of Heat Treatment, Mater. Sci. & Eng. A., 2017, 707, p 136–147. https://doi.org/10.1016/j.msea.2017.08.093

Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials, ASTM E 21, Annual book of ASTM standards, part 3, ASTM 2009, www.astm.org

P. Rodriguez, Serrated Plastic Flow, Bull. Mater. Sci., 1984, 6(4), p 653–663. https://doi.org/10.1007/BF02743993

S. Nalawade, S. Mahadevan, J.B. Singh, K. Ramaswamy, and A. Verma, Serrated Yielding in Alloy 718, 7th International Symposium on Super alloy 718 and Derivatives, E.A. Ott, J.R. Groh, A. Banik, I. Dempster, T.P. Grabb, R. Helmix, X. Liu, A. Mitchell, G.P. Sjoberg, and A. Wusatowska-sarnek, Ed., The Minerals, Metals & Materials Society, 2010, p 809–823. https://doi.org/10.7449/2010/superalloys_2010_809_823

R.A. Mulford and U.F. Kocks, New Observations on the Mechanisms of Dynamic Strain Aging and of Jerky Flow, Acta Metall., 1979, 27, p 1125–1134. https://doi.org/10.1016/0001-6160(79)90130-5

A. Kimura and H.K. Birnbaum, Anomalous Strain Rate Dependence of the Serrated Flow in NiH and NiCH Alloys, Acta Metall. Mater., 1990, 38, p 1343–1348. https://doi.org/10.1016/0956-7151(90)90206-V

U.F. Kocks, R.E. Cook, and R.A. Mulford, Strain Aging and Strain Hardening in NiC Alloys, Acta Metall., 1985, 33, p 623–638. https://doi.org/10.1016/0001-6160(85)90026-4

Y. Nakada and A.S. Keh, Serrated Flow in Ni-C Alloys, Acta Metall., 1970, 18, p 437–443. https://doi.org/10.1016/0001-6160(70)90129-X

A. Portevin and F. Le Chatelier, Sur un phénomène observe lors de l’essai de traction d’alliages en corns de trans formation, Comptes Rendus Acad. Sci. Paris., 1923, 176, p 507–510

L.H. de Almeida, P.R.O. Emygdio, and I. Le May, Activation Energy Calculation and Dynamic Strain Aging in Austenitic Stainless Steel, Scr. Metall. Mater., 1994, 31(5), p 505–510. https://doi.org/10.1016/0956-716X(94)90134-1

L.H. de Almeida, I. Le May, and P.R.O. Emygdio, Mechanistic Modeling of Dynamic Strain Aging in Austenitic Stainless Steels, Mater. Charact., 1998, 41(4), p 137–150. https://doi.org/10.1016/S1044-5803(98)00031-X

L. Fournier, D. Delafosse, and T. Magnin, Oxidation Induced Intergranular Cracking and Portevin–Le Chatelier Effect in Nickel Base Superalloy 718, Mater. Sci. Eng. A, 2001, 316, p 166–173. https://doi.org/10.1016/S0921-5093(01)01224-2

C.L. Hale, W.S. Rollings, and M.L. Weaver, Activation Energy Calculations for Discontinuous Yielding in Inconel 718SPF, Mater. Sci. Eng., A, 2001, 300, p 153–164. https://doi.org/10.1016/S0921-5093(00)01470-2

S.A. Nalawade, M. Sundararaman, R. Kishore, and J.G. Shah, The Influence of Aging on the Serrated Yielding Phenomena in a Nickel-Base Superalloy, Scr. Mater., 2008, 59, p 991–994. https://doi.org/10.1016/j.scriptamat.2008.07.004

M.L. Weaver and C.S. Hale, Effects of Precipitation on Serrated Yielding in Inconel 718, Superalloys 718, 625, 706 and Various Derivatives.,E.A.Loria, Ed., The Minerals, Metals & Materials Society, 2001, p 421–432. https://doi.org/10.7449/2001/superalloys_2001_421_432

H. Hänninen, M. Ivanchenko, Y. Yagodzinskyy, V. Nevdacha, U. Ehrnstén, and P. Aaltonen, Dynamic strain aging of Ni-base alloys Inconel 600 and 690, Proc. 12th Int. Conf. Environ. Degrad. Mater. Nucl. Power Syst, (Water React)., T.R. Allen, P.J. King and L. Nelson, Ed., The Minerals, Metals & Materials Society, Salt Lake City, Utah, USA, 2005, p 1423–1430. http://lib.tkk.fi/Diss/2010/isbn9789526034454/article5.pdf.

R.B. Frank, C.G. Roberts, and J. Zhang, Effect of Nickel Content on Delta Solvus Temperature and Mechanical Properties of Alloy 718, 7th International Symposium on Super alloy 718 and Derivatives, E.A.Ott, J.R.Groh, A.Banik, I. Dempster, T.P. Grabb, R. Helmix, X. Liu, A. Mitchell, G.P. Sjoberg, and A. Wusatowska-sarnek, Ed., The Minerals, Metals & Materials Society, 2010, p 725–736. https://doi.org/10.1002/9781118495223.ch56.

Acknowledgments

The authors are great full to Dr. Sivakumar, Head, HWMD for extending heat treatment facility to carry out this work. The authors also acknowledge the support of Mr. Chenna Krishna S, MPD toward DSC experiments and Dr. Jalaja K, MCD for XRD data analysis. Authors wish to thank GD, MMG and DD, MME for encouragement and support provided and also thank Director, VSSC for his continuous support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Fig. S1

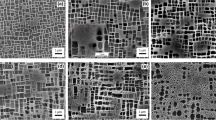

Microstructure of specimen prepared from gauge portions near the fractured edge of sample in STA + BC condition tested at 700 °C showing (a) STEM image showing fine precipitates within the grains (b) and (c) STEM image and BFTEM image showing grain boundary triple junction and precipitates distributed along the grain boundaries, respectively (TIFF 493 kb)

Rights and permissions

About this article

Cite this article

Manikandan, P., Sudarshan Rao, G., Saravanan, K. et al. High Temperature Tensile Behavior of a Nickel-Based Superalloy 55Ni-17Cr-12Fe-9Mo-2Nb-1.5Al Used in Launch Vehicle Applications. J. of Materi Eng and Perform 29, 377–390 (2020). https://doi.org/10.1007/s11665-019-04525-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04525-x