Abstract

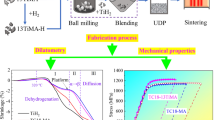

In this paper, the powder metallurgy method was employed to prepare titanium alloys with high-carbon ferrochrome (HCFeCr). With the HCFeCr addition, the size of the β grains decreased and the lamellae of the α phase became thinner. The TiC strengthening phase precipitated at the grain boundaries, resulting in the inhibition of the β grain growth and hardness enhancement. In addition, Fe and Cr as β-stabilizing elements existed in the enriched β-Ti phase, which increased the β phase amount. The strength improvement was attributed to grain size optimization and strengthening phase formation. With the 9 wt.% HCFeCr addition, the corresponding Vickers hardness increased to 480 HV, which is 60% higher than the Ti6Al4V alloy. The tensile and yield strength was 1228 and 1140 MPa, respectively. The addition of HCFeCr can effectively enhance the strength and hardness while reducing the cost. This is a promising additive to obtain low-cost Ti alloys with high mechanical properties.

Similar content being viewed by others

References

C. Leyens and M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-YCH, Hoboken, 2003

D. Banerjee and J.C. Williams, Perspectives on Titanium Science and Technology, Acta Mater., 2013, 61(3), p 844–879

F.H.S. Froes, M.N. Gungor, and M.A. Imam, Cost-Affordable Titanium: the Component Fabrication Perspective, JOM, 2007, 59(6), p 28–31

M.A. Imam, F.H. Froes, and R.G. Reddy, Research and Development of low-Cost Titanium Alloys for Biomedical Applications, Key Eng. Mater., 2013, 551, p 133–139

R. Zhang, D.J. Wang, S.Q. Liu, H.S. Ding, and S.J. Yuan, Hot Deformation Characterization of Lamellar Ti-43Al-2Si Alloy Fabricated By Cold Crucible Continuous Casting, J. Alloys Compd., 2016, 688, p 542–552

S. Schafföner, C.G. Aneziris, H. Berek, J. Hubálková, B. Rotmann, and B. Friedrich, Corrosion Behavior of Calcium Zirconate Refractories in Contact with Titanium Aluminide Melts, J. Eur. Ceram. Soc., 2015, 35(3), p 1097–1106

K. Gupta and R.F. Laubscher, Sustainable Machining of Titanium Alloys: A Critical Review, Proc. Inst. Mech. Eng., 2017, 231(14), p 2543–2560

T.D. Popovici and I. Ciocan, Experimental Study on Cutting Forces at Ti6Al4V Milling, Adv. Mater. Res., 2015, 1128, p 288–292

C.R.F. Azevedo, D. Rodrigues, and F.B. Neto, Ti-Al-V Powder Metallurgy (pm) via the Hydrogenation–Dehydrogenation (hdh) Process, J. Alloys Compd., 2003, 353(1), p 217–227

B. Sharma, S.K. Vajpai, and K. Ameyama, Microstructure and Properties of Beta Ti-Nb Alloy Prepared By Powder Metallurgy Route Using Titanium Hydride Powder, J. Alloys Compd., 2012, 656, p 978–986

A.T. Sidambea, I.A. Figueroaa, H.G.C. Hamiltonb, and I. Todda, Metal Injection Moulding of CP-Ti Components for Biomedical Applications, J. Mater. Process. Technol., 2012, 212(7), p 1591–1597

P. Perssona, A.E.W. Jarforsb, and S. Savagec, Self-Propagating High-Temperature Synthesis and Liquid-Phase Sintering of TiC/Fe Composites, J. Mater. Process. Technol., 2011, 127(2), p 131–139

X.X. Ye, B. Chen, J.H. Shen, J. Umeda, and K. Kondoh, Microstructure and Strengthening Mechanism of Ultrastrong and Ductile Ti-xSn Alloy Processed by Powder Metallurgy, J. Alloys Compd., 2017, 709(30), p 381–393

D.G. Savvakin, A. Carman, O.M. Ivasishin, M.V. Matviychuk, A.A. Gazder, and E.V. Pereloma, Effect of Iron Content on Sintering Behavior of Ti-V-Fe-Al near-β Titanium Alloy, Metall. Mater. Trans. A, 2012, 43(2), p 716–723

L. Bolzoni, E. Herraiz, E.M. Ruiz-Navas, and E. Gordo, Study of the Properties of Low-Cost Powder Metallurgy Titanium Alloys by 430 Stainless Steel Addition, Mater. Des., 2014, 60(8), p 628–636

C.J. Bettles, S. Tochon, M.A. Gibson, B.A. Welk, and H.L. Fraser, Microstructure and Mechanical Properties of Titanium Aluminide Compositions Containing Fe, Mater. Sci. Eng. A, 2013, 575(6A), p 152–159

L. Bolzonia, E.M. Ruiz-Navasb, and E. Gordob, Quantifying the Properties of Low-Cost Powder Metallurgy Titanium Alloys, Mater. Sci. Eng. A, 2017, 687, p 47–53

R. Licheri, R. Orrù, and G. Cao, Chemically-Activated Combustion Synthesis of TiC-Ti Composites, Mater. Sci. Eng. A, 2004, 367(1), p 185–197

V.A. Popov, M. Burghammer, M. Rosenthal, and A. Kotov, In Situ Synthesis of TiC Nano-Reinforcements in Aluminum Matrix Composites During Mechanical Alloying, Composites Part B, 2018, 145, p 57–61

B. AlMangour, D. Grzesiak, and J. Yang, In-situ Formation of Novel TiC-Particle-Reinforced 316L Stainless Steel Bulk-Form Composites By Selective Laser Melting, J. Alloys Compd., 2017, 706, p 409–418

X. Yuan, G. Liu, H. Jin, and K. Chen, In Situ Synthesis of TiC Reinforced Metal Matrix Composite (MMC) Coating By Self-Propagating High Temperature Synthesis (SHS), J. Alloys Compd., 2011, 509(30), p 301–303

Standard E8, Standard test methods for tension testing of metallic materials, 2004

G.A. Salishchev, S.V. Zerebtsov, S.Y. Mironov, and S.L. Semiatin, Formation of Grain Boundary Misorientation Spectrum in Alpha-Beta Titanium Alloys with Lamellar Structure Under Warm and Hot Working, Mater. Sci. Forum, 2004, 467–470, p 501–506

J.L. Murray, Phase Diagrams of Binary Titanium Alloys, ASM International, Metals Park, Ohio, 1987

H. Nakajima, K. Ogasawara, S. Yamaguchi, and M. Koiwa, Diffusion of Chromium in α-Titanium and its Alloys, Mater. Trans. JIM, 1990, 1(4), p 249–254

D.B. Lee, K.B. Park, H.W. Jeong, and S.E. Kim, Mechanical and Oxidation Properties of Ti-xFe-ySi Alloys, Mater. Sci. Eng. A, 2002, 328(1), p 161–168

J. Jiang, S. Li, W. Zhang, W. Yu, and Y. Zhou, In Situ Formed TiCx in High Chromium White Iron Composites: Formation Mechanism and Influencing Factors, J. Alloys Compd., 2019, 788, p 873–880

B. AlMangour, D. Grzesiak, and J. Yang, In situ Formation of TiC-Particle-Reinforced Stainless Steel Matrix Nanocomposites During Ball Milling: Feedstock Powder Preparation for Selective Laser Melting at Various Energy Densities, Powder Technol, 2018, 326, p 467–478

ASTM standard B367, Specification for titanium and titanium alloy castings, 2013.

Acknowledgments

This work was supported by the State Key Lab of Advanced Metals and Materials (No. 2018-Z06). AV acknowledges support from the National Science Foundation (IRES 1358088).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, B., Zhang, C., Guo, Z. et al. High-Carbon Ferrochrome Effects on Microstructure and Mechanical Properties of Powder Metallurgy Titanium Alloys. J. of Materi Eng and Perform 28, 5361–5368 (2019). https://doi.org/10.1007/s11665-019-04282-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04282-x