Abstract

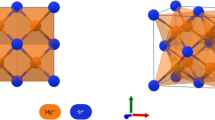

The microstructural evolution and impact wear behavior of Al-alloyed ultra-high-Mn austenitic cast steel were investigated after different heat treatments, including quenching (Q) and quenching + aging (Q + A). Another ultra-high-Mn austenitic cast steel without Al was compared under the same experimental condition. After Q + A, Al addition contributed to the precipitation of κ-carbides which improves the yield strength and wear resistance of the austenite matrix. However, the mechanical properties and wear resistance of the Al-free steel were strongly deteriorated due to the precipitation of plate-like M3C-type carbides, as well as the worn surface of the Al-free steel had the feature of micro-scratches. After Q + A (2 h), the Al-alloyed steel obtained optimal wear resistance and the main wear feature was strain fatigue. But, excessive aging time (4 h) would lead to a large fragile peeling from the worn surface and the wear resistance was decreased. Also, the worn subsurface microstructures with different heat treatments were observed by transmission electron microscopy (TEM). These results show that the deformation microstructures of the Al-free steel contained stacking faults, dislocation tangle and deformation twins. The deformation character of Al-alloyed steel is dominated by planar glide, and with increase in the aging time, planar dislocation substructures gradually evolved, relating to dislocation pileups, Taylor lattices and micro-bands.

Similar content being viewed by others

References

S. Bhattacharyya, A Friction and Wear Study of Hadfield Manganese Steel, Wear, 1966, 9(6), p 451–461. https://doi.org/10.1016/0043-1648(66)90136-0

A.K. Srivastava and K. Das, Microstructural Characterization of Hadfield Austenitic Manganese Steel, J. Mater. Sci., 2008, 43(16), p 5654–5658. https://doi.org/10.1007/s10853-008-2759-y

Y.H. Wen, H.B. Peng, H.T. Si, R.L. Xiong, and D. Raabe, A Novel High Manganese Austenitic Steel with Higher Work Hardening Capacity and Much Lower Impact Deformation Than Hadfield Manganese Steel, Mater. Des., 2014, 55, p 798–804. https://doi.org/10.1016/j.matdes.2013.09.057

R. Xiong, H. Peng, S. Wang, H. Si, and Y. Wen, Effect of Stacking Fault Energy on Work Hardening Behaviors in Fe-Mn-Si-C High Manganese Steels by Varying Silicon and Carbon Contents, Mater. Des., 2015, 85, p 707–714. https://doi.org/10.1016/j.matdes.2015.07.072

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot, and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C Alloys, Mater. Sci. Eng. A, 2004, 387, p 158–162. https://doi.org/10.1016/j.msea.2004.01.059

O.A. Zambrano, J. Valdés, Y. Aguilar, J.J. Coronado, S.A. Rodríguez, and R.E. Logé, Hot Deformation of a Fe-Mn-Al-C Steel Susceptible of κ-Carbide Precipitation, Mater. Sci. Eng. A, 2017, 689, p 269–285. https://doi.org/10.1016/j.msea.2017.02.060

D.T. Pierce, J.A. Jiménez, J. Bentley, D. Raabe, C. Oskay, and J.E. Wittig, The Influence of Manganese Content on the Stacking Fault and Austenite/ε-Martensite Interfacial Energies in Fe-Mn-(Al-Si) Steels Investigated by Experiment and Theory, Acta Mater., 2014, 68, p 238–253. https://doi.org/10.1016/j.actamat.2014.01.001

H. Idrissi, K. Renard, D. Schryvers, and P.J. Jacques, On the Relationship Between the Twin Internal Structure and the Work-Hardening Rate of TWIP Steels, Scr. Mater., 2010, 63(10), p 961–964. https://doi.org/10.1016/j.scriptamat.2010.07.016

R. Song, C. Cai, S. Liu, Y. Feng, and Z. Pei, Stacking Fault Energy and Compression Deformation Behavior of Ultra-High Manganese Steel, Procedia Eng., 2017, 207, p 1809–1814. https://doi.org/10.1016/j.proeng.2017.10.943

Y.N. Dastur and W.C. Leslie, Mechanism of Work Hardening in Hadfield Manganese Steel, Metall. Mater. Trans. A, 1981, 12(5), p 749–759. https://doi.org/10.1007/BF02648339

J.D. Yoo and K.-T. Park, Micro-Band-Induced Plasticity in a High Mn-Al-C Light Steel, Mater. Sci. Eng. A, 2008, 496, p 417–424. https://doi.org/10.1016/j.msea.2008.05.042

G. Frommeyer and U. Briix, Microstructures and Mechanical Properties of High-Strength Fe-Mn-Al-C Light-Weight TRIPLEX Steels, Steel Res. Int., 2006, 77, p 627–633. https://doi.org/10.1002/srin.200606440

J.D. Yoo, S.W. Hwang, and K.-T. Park, Origin of Extended Tensile Ductility of a Fe-28Mn-10Al-1C Steel, Metall. Mater. Trans. A, 2009, 40, p 1520–1523. https://doi.org/10.1007/s11661-009-9862-9

H. Ding, D. Han, J. Zhang, Z. Cai, Z. Wu, and M. Cai, Tensile Deformation Behavior Analysis of Low Density Fe-18Mn-10Al-xC Steels, Mater. Sci. Eng. A, 2016, 652, p 69–76. https://doi.org/10.1016/j.msea.2015.11.071

O.A. Zambrano, A General Perspective of Fe-Mn-Al-C Steels, J. Mater. Sci., 2018, 53(20), p 14003–14062. https://doi.org/10.1007/s10853-018-2551-6

D. Canadinc, H. Sehitoglu, H.J. Maier, and Y.I. Chumlyakov, Show More Strain Hardening Behavior of Aluminum Alloyed Hadfield Steel Single Crystals, Acta Mater., 2005, 53(6), p 1831–1842. https://doi.org/10.1016/j.actamat.2004.12.033

M. Abbasi, S. Kheirandish, Y. Kharrazi, and J. Hejazi, The Fracture and Plastic Deformation of Aluminum Alloyed Hadfield Steels, Mater. Sci. Eng. A, 2009, 513, p 72–76. https://doi.org/10.1016/j.msea.2009.02.023

O.A. Zambrano, Y. Aguilar, J. Valdés, S.A. Rodríguez, and J.J. Coronado, Effect of Normal Load on Abrasive Wear Resistance and Wear Micromechanisms in FeMnAlC Alloy and Other Austenitic Steels, Wear, 2016, 348, p 61–68. https://doi.org/10.1016/j.wear.2015.11.019

Y. Feng, R. Song, Z. Pei, R. Song, and G. Dou, Effect of Aging Isothermal Time on the Microstructure and Room-Temperature Impact Toughness of Fe-24.8 Mn-7.3 Al-1.2 C Austenitic Steel with κ-Carbides Precipitation, Met. Mater. Int., 2018, 2018, p 1–12. https://doi.org/10.1007/s12540-018-0112-9

E. Welsch, D. Ponge, S.M. Hafez-Haghighat, S. Sandlöbes, P. Choi, M. Herbig, S. Zaefferer, and D. Raabe, Strain Hardening by Dynamic Slip Band Refinement in a High-Mn Lightweight Steel, Acta Mater., 2016, 116, p 188–199. https://doi.org/10.1016/j.actamat.2016.06.037

D. Kuhlmann-Wilsdorf, Theory of Plastic Deformation: Properties of Low Energy Dislocation Structures, Mater. Sci. Eng. A, 1989, 113, p 1–41. https://doi.org/10.1016/0921-5093(89)90290-6

B. Bay, N. Hansen, and D. Khulmann-Wilsdorf, Deformation Structures in Lightly Rolled Pure Aluminium, Mater. Sci. Eng. A, 1989, 113, p 385–397. https://doi.org/10.1016/0921-5093(89)90325-0

I. Gutierrez-Urrutia and D. Raabe, Influence of Al Content and Precipitation State on the Mechanical Behavior of Austenitic High-Mn Low-Density Steels, Scr. Mater., 2013, 68(6), p 343–347. https://doi.org/10.1016/j.scriptamat.2012.08.038

O.A. Zambrano, J. Valdés, L.A. Rodriguez, D. Reyes, E. Snoeck, S.A. Rodríguez, and J.J. Coronado, Elucidating the Role of κ-Carbides in FeMnAlC Alloys on Abrasion Wear, Tribol. Int., 2019, 135, p 421–431. https://doi.org/10.1016/j.triboint.2019.03.002

K. Sato, M. Ichinose, Y. Hirotsu, and Y. Inoue, Effects of Deformation Induced Phase Transformation and Twinning on the Mechanical Properties of Austenitic Fe-Mn-Al Alloys, ISIJ Int., 1989, 29(10), p 868–877. https://doi.org/10.2355/isijinternational.29.868

J.P. Hirth, Thermodynamics of Stacking Faults, Metall. Mater. Trans. B, 1970, 1(9), p 2367. https://doi.org/10.1007/BF03038365

T.S. Byun, On the Stress Dependence of Partial Dislocation Separation and Deformation Microstructure in Austenitic Stainless Steels, Acta Mater., 2003, 51(11), p 3063–3071. https://doi.org/10.1016/S1359-6454(03)00117-4

S. Allain, J.-P. Chateau, and O. Bouaziz, A Physical Model of the Twinning-Induced Plasticity Effect in a High Manganese Austenitic Steel, Mater. Sci. Eng. A, 2004, 387, p 143–147. https://doi.org/10.1016/j.msea.2004.01.060

T. Steffens, C. Schwink, A. Korner, and H.P. Karnthaler, Transmission Electron Microscopy Study of the Stacking-Fault Energy and Dislocation Structure in CuMn Alloys, Philos. Mag. A, 1987, 56, p 161–173. https://doi.org/10.1080/01418618708205159

G. Saller, K. Spiradek-Hahn, C. Schen, and H. Clemens, Microstructural Evolution of Cr-Mn-N Austenitic Steels During Cold Work Hardening, Mater. Sci. Eng. A, 2006, 427, p 246–254. https://doi.org/10.1016/j.msea.2006.04.020

K.-T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, and C.S. Lee, Stacking Fault Energy and Plastic Deformation of Fully Austenitic High Manganese Steels: Effect of Al Addition, Mater. Sci. Eng. A, 2010, 527(16–17), p 3651–3661. https://doi.org/10.1016/j.msea.2010.02.058

J.D. Yoo, S.W. Hwang, and K.-T. Park, Factors Influencing the Tensile Behavior of a Fe-28Mn-9Al-0.8 C Steel, Mater. Sci. Eng. A, 2009, 508(1–2), p 234–240. https://doi.org/10.1016/j.msea.2008.12.055

M.J. Yao, E. Welsch, D. Ponge, S.M.H. Haghighat, S. Sandlöbes, P. Choi, M. Herbig, I. Bleskov, T. Hickel, M. Lipinska-Chwalek, P. Shanthraj, C. Scheu, S. Zaefferer, B. Gault, and D. Raabe, Strengthening and Strain Hardening Mechanisms in a Precipitation-Hardened High-Mn Lightweight Steel, Acta Mater., 2017, 140, p 258–273. https://doi.org/10.1016/j.actamat.2017.08.049

C. Haase, C. Zehnder, T. Ingendahl, A. Bikar, F. Tang, B. Hallstedt, W. Hu, W. Bleck, and D.A. Molodov, On the Deformation Behavior of κ-Carbide-Free and κ-Carbide-Containing High-Mn Light-Weight Steel, Acta Mater., 2017, 122, p 332–343. https://doi.org/10.1016/j.actamat.2016.10.006

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, Y., Song, R., Peng, S. et al. Microstructures and Impact Wear Behavior of Al-Alloyed High-Mn Austenitic Cast Steel After Aging Treatment. J. of Materi Eng and Perform 28, 4845–4855 (2019). https://doi.org/10.1007/s11665-019-04265-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04265-y