Abstract

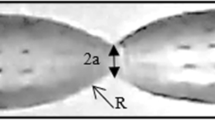

Triaxial state of stress is usually generated in the necked zone because of neck geometry, and as a consequence proper correction of true tensile stress–strain curve after necking is mandatory. Various correction factors like Bridgman, Davidenkov and Spiridonova, Siebel and Schwaigere are available in the published literature to calculate true stress from mean axial stress. Similarly true strains can be calculated from the minimum diameters of the round specimen in the necked region for various true stress levels. But experimental determination of correction factors and minimum diameters of the round specimen in the necked region is a cumbersome task. This investigation shows a simplified procedure to determine true strains and the correction factors from digital image correlation-based local strain measurement in the necked region. The present procedure is validated by experimental results of rail steel.

Similar content being viewed by others

References

M. Joun, I. Choi, J. Eom, and M. Lee, Finite Element Analysis of Tensile Testing with Emphasis on Necking, Comput. Mater. Sci., 2007, 41(1), p 63–69

P.W. Bridgman, Studies in Large Plastic Flow and Fracture, McGraw Hill, New York, 1952

P.W. Bridgman, The Stress Distribution at the Neck of a Tension Specimen, Trans. Am. Soc. Met., 1944, 32, p 553–574

F. Zhu, P. Bai, J. Zhang, D. Lei, and X. He, Measurement of True Stress–Strain Curves and Evolution of Plastic Zone of Low Carbon Steel Under Uniaxial Tension Using Digital Image Correlation, Opt. Lasers Eng., 2015, 65, p 81–88

M. Kamaya and M. Kawakubo, A Procedure for Determining the True Stress–Strain Curve Over a Large Range of Strains Using Digital Image Correlation and Finite Element Analysis, Mech. Mater., 2011, 43, p 243–253

M.S. Joun, J.G. Eom, and M.C. Lee, A New Method for Acquiring True Stress–Strain Curves Over a Large Range of Strains Using a Tensile Test and Finite Element Method, Mech. Mater., 2008, 40, p 586–593

G. Mirone, A New Model for the Elastoplastic Characterization and the Stress–Strain Determination on the Necking Section of a Tensile Specimen, Int. J. Solids Struct., 2004, 41(13), p 3545–3565

Z.L. Zhang, M. Hauge, J. Odegard, and C. Thaulow, Determining True Stress–Strain Curve from Tensile Specimens with Rectangular Cross-Section, Int. J. Solids Struct., 1999, 36, p 3497–3516

A. Nasser, A. Yadav, P. Pathak, and T. Altan, Determination of the Flow Stress of Five AHSS Sheet Materials (DP 600, DP 780, DP780-CR, DP 780-HY and TRIP 780) Using the Uniaxial Tensile and the Biaxial Viscous Pressure Bulge (VPB) Tests, J. Mater. Process. Technol., 2010, 210, p 429–436

N. Tardif and S. Kyriakides, Determination of Anisotropy and Material Hardening for Aluminum Sheet Metal, Int. J. Solids Struct., 2012, 49(25), p 3496–3506

J.-H. Kim, A. Serpantié, F. Barlat, F. Pierron, and M.-G. Lee, Characterization of the Post-necking Strain Hardening Behavior Using the Virtual Fields Method, Int. J. Solids Struct., 2013, 50, p 3829–3842

M.A. Iadicola, Validation of Uniaxial Data Beyond Uniform Elongation, in Proceedings of 8th the International Conference and Workshop on Numerical Simulation of 3DSheet Metal Forming Processes, AIP Conf. Proc., 2011, 1383, pp 742–749.

K. Zhao, L. Wang, Y. Chang, and J. Yan, Identification of Post-necking Stress–Strain Curve for Sheet Metals by Inverse Method, Mech. Mater., 2016, 92, p 107–118

X. Zhuang, Z. Zhao, H. Li, and H. Xiang, Experimental Methodology for Obtaining the Flow Curve of Sheet Materials in a Wide Range of Strains, Steel Res. Int., 2013, 84(2), p 146–154

L. Wang and W. Tong, Identification of Post-necking Strain Hardening Behavior of Thin Sheet Metals from Image-Based Surface Strain Data in Uniaxial Tension Tests, Int. J. Solids Struct., 2015, 75-76, p 12–31

S.K. Paul, S. Roy, S. Sivaprasad, H.N. Bar, and S. Tarafder, Local Ratcheting Response in Dissimilar Metal Weld Joint: Characterization Through Digital Image Correlation Technique, J. Mater. Eng. Perform., 2017, 26(10), p 4953–4963

H. Ghadbeigi, C. Pinna, S. Celotto, and J.R. Yates, Local Plastic Strain Evolution in a High Strength Dual-Phase Steel, Mater. Sci. Eng. A, 2010, 527(18–19), p 5026–5032

H. Ghadbeigi, C. Pinna, and S. Celotto, Failure Mechanisms in DP600 Steel: Initiation, Evolution and Fracture, Mater. Sci. Eng. A, 2013, 588, p 420–431

L. Dong, S. Li, and J. He, Ductile Fracture Initiation of Anisotropic Metal Sheets, J. Mater. Eng. Perform., 2017, 26(7), p 3285–3298

Z. Chen, G. Fang, and J.-Q. Zhao, Formability Evaluation of Aluminum Alloy 6061-T6 Sheet at Room and Elevated Temperatures, J. Mater. Eng. Perform., 2017, 26(9), p 4626–4637

G. Leroy, J. Embury, G. Edwards et al., A Model of Ductile Fracture Based on the Nucleation and Growth of Voids, Acta Metall., 1981, 29, p 1509–1522

E. Siebel and S. Schwaigere, Mechanics of Tensile Test, Arch Eisenhuttenwes., 1948, 19, p 145–152 (in German)

N.N. Davidenkov and N.I. Spiridonova, Mechanical Method of Testing Analysis of the State of Stress in the Neck of a Tension Test Specimen, Proc. Am. Soc. Test. Mater., 1947, 46, p 1147–1158

Z. Ling, Uniaxial True Stress–Strain After Necking, AMP J. Technol., 1996, 5, p 37–48

R.B. Joshi, A.E. Bayoumi, and H.M. Zbib, The Use of Digital Processing in Studying Stretch-Forming Sheet Metal, Exp. Mech., 1992, 32(2), p 117–123

http://www.lavision.de/en/products/strainmaster/strainmaster-dic.php

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paul, S.K., Roy, S., Sivaprasad, S. et al. A Simplified Procedure to Determine Post-necking True Stress–Strain Curve from Uniaxial Tensile Test of Round Metallic Specimen Using DIC. J. of Materi Eng and Perform 27, 4893–4899 (2018). https://doi.org/10.1007/s11665-018-3566-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3566-5