Abstract

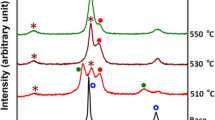

The low-alloy steel was nitrided in a pure NH3 gas atmosphere at 640 ~ 660 °C for 2 h, i.e., high-temperature gas nitriding (HTGN), followed by tempering at 225 °C, which can produce a high property surface coating without brittle compound (white) layer. The steel was also plasma nitriding for comparison. The composition, microstructure and microhardness of the nitrided and tempered specimens were examined, and their tribological behavior investigated. The results showed that the as-gas-nitrided layer consisted of a white layer composed of FeN0.095 phase (nitrided austenite) and a diffusional zone underneath the white layer. After tempering, the white layer was decomposed to a nano-sized (α-Fe + γ′-Fe4N + retained austenite) bainitic microstructure with a high hardness of 1150HV/25 g. Wear test results showed that the wear resistance and wear coefficient yielded by the complex HTGN plus tempering were considerably higher and lower, respectively, than those produced by the conventional plasma nitriding.

Similar content being viewed by others

References

W.P. Tong, C.Z. Liu, W. Wang, N.R. Tao, Z.B. Wang, L. Zuo, and J.C. He, Gaseous Nitriding of Iron with a Nanostructured Surface Layer, Scr. Mater., 2007, 57, p 533–536

J. Mongis, J.P. Peyre, and C. Tournier, Nitriding of Microalloyed Steels, Heat Treat. Met., 1984, 3, p 71–75

T. Steiner and E.J. Mittemeijer, Alloy Element Nitride Development in Ferritic Fe-Based Materials Upon Nitriding: A Review, J. Mater. Eng. Perform., 2016, 25, p 2091–2102

J.A. Kirk, G.W. Egerton, and B.D. Sartwell, Wear and Friction of Nitrogen Ion Implanted Steel, J. Lubr. Technol., 1983, 105(2), p 239–244

A. Cohen and A. Rosen, The Influence of the Nitriding Process on the Dry Wear Resistance of 15-5PH Stainless Steel, Wear, 1986, 108, p 157–168

A. Celik and S. Karadeniz, Investigation of Compound Layer Formed During Ion Nitriding of AISI, 4140 Steel, Surf. Coat. Technol., 1996, 80, p 283–286

C. Kwietniewski, W. Fontana, C. Moraes, A.D.S. Rocha, T. Hirsch, and A. Regaly, Nitrided Layer Embrittlement Due to Edge Effect on Duplex Treated AISI, M2 High-Speed Steel, Surf. Coat. Technol., 2004, 179, p 27–32

D. Nolan, V. Leskovsek, and M. Jenko, Estimation of Fracture Toughness of Nitride Compound Layers on Tool Steel by Application of the Vickers Indentation Method, Surf. Coat. Technol., 2006, 201, p 182–188

T. Doggart and H. Gupta, An Investigation of Case-Hardened Nitralloy, J. Mater. Sci., 1997, 32, p 2059–2062

M. Keddam, B. Bouarour, R. Kouba, and R. Chegroune, Growth Kinetics of the Compound Layers: Effect of the Nitriding Potential, Phys. Proc., 2009, 2, p 1399–1403

S. Srikanth, P. Saravanan, A. Joseph, K. Ravl, Surface Modification of Commercial Low-Carbon Steel using Glow Discharge Nitrogen Plasma and its Characterization, J. Mater. Eng. Perform. 2013, 22, p 2610–2622

M.J. Hu, J.S. Pan, Z.C. Zhu, and C.C. Qiu, A Special Phase Transformation Phenomenon in High-Nitrogen Austenite, Mater. Lett., 2001, 50, p 225–229

D.L. Jiao, C.P. Luo, and J.W. Liu, Isothermal Transformation of High-Nitrogen Austenite, Scr. Mater., 2007, 56, p 613–616

D.L. Jiao, C.P. Luo, and J.W. Liu, Grain Boundary Transformation Character in Fe-N Austenite, Mater. Lett., 2012, 66, p 147–149

D.L. Jiao, C.P. Luo, and J.W. Liu, Morphology and Crystallographic Orientation Relationship in Isothermally Transformed Fe-N Austenite, Mater. Char., 2014, 88, p 52–57

X.A. Wang, M.F. Yan, C.S. Zhang, and Y.X. Zhang, Microstructure and Mechanical Properties of Surface Layer of M50NiL Steel Plasma Nitride, Surf. Eng., 2014, 30(3), p 218–223

P. Jessner, R. Danoix, B. Hannoyer, and F. Danoix, Investigations of the Nitrided Subsurface Layers of an Fe-Cr Model Alloy, Ultramicroscopy, 2009, 109, p 530–534

T. Steiner, S.R. Meka, B. Rheingans, E. Bischoff, T. Waldenmaier, G. Yeli, T.L. Martin, Paul A.J. Bagot, M.P. Moody, and E.J. Mittemeijer, Continuous and Discontinuous Precipitation in Fe-1 at.%Cr-1 at.%Mo Alloy Upon Nitriding; Crystal Structure and Composition of Ternary Nitrides, Phil. Mag., 2016, 96, p 1509–1537

D.L. Jiao, C.L. Luo, and J.W. Liu, Intermediate Temperature Transformation of High Nitrogen Austenite, Acta. Metall. Sin., 2007, 3, p 337–343

H. Kato, T.S. Eyre, and B. Ralph, Sliding Wear Characteristics of Nitrided Steels, Surf. Eng., 1994, 10, p 65–74

B.Y. Wang, Z.B. Hou, W. Wang, and B. Zhao, Investigation of Gas Nitriding on Wear and Corrosion Behavior of 40 Cr Steel, Adv. Mater. Res., 2011, 2011(311–313), p 674–678

P. Zhang, F.C. Zhang, Z.G. Yan, and C.L. Zheng, N Rich Nanocrystalline Bainite in Surface Layer of Carbon Steel, Surf. Eng., 2013, 29(5), p 331–335

Acknowledgments

This project was financially supported by the National Natural Science Fund of China (51001049, 51271079), the Guangdong Natural Science Fund (2016A030313450, 2015A030313223) and the Fundamental Research Funds for the Central Universities (2013ZM033, 2015ZM065).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiao, D., Li, M., Ding, H. et al. Modification of Low-Alloy Steel Surface by High-Temperature Gas Nitriding Plus Tempering. J. of Materi Eng and Perform 27, 361–367 (2018). https://doi.org/10.1007/s11665-018-3141-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3141-0