Abstract

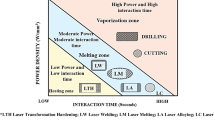

In this work, we describe a method to improve the bonding of an immiscible Mg/steel system using Ni as an interlayer by coating it on the steel surface. Laser welding-brazing of AZ31B Mg alloy to Ni-coated Q235 steel using Mg-based filler was performed in a lap configuration. The influence of laser power on the weld characteristics, including joint appearance, formation of interfacial reaction layers and mechanical properties was investigated. The results indicated that the presence of the Ni-coating promoted the wetting of the liquid filler metal on the steel surface. A thermal gradient along the interface led to the formation of heterogeneous interfacial reaction layers. When using a low laser power of 1600 W, the reaction products were an FeAl phase in the direct laser irradiation zone, an AlNi phase close to the intermediate zone and mixtures of AlNi phase and an (α-Mg + Mg2Ni) eutectic structure near the interface at the seam head zone. For high powers of more than 2000 W, the FeAl phase grew thicker in the direct laser irradiation zone and a new Fe(Ni) transition layer formed at the interface of the intermediate zone and the seam head zone. However, the AlNi phase and (α-Mg + Mg2Ni) eutectic structure were scattered at the Mg seam. All the joints fractured at the fusion zone, indicating that the improved interface was not the weakest joint region. The maximum tensile-shear strength of the Mg/Ni-coated steel joint reached 190 N/mm, and the joint efficiency was 70% with respect to the Mg alloy base metal.

Similar content being viewed by others

References

E. Ghali, W. Dietzel, and K. Kainer, General and Localized Corrosion of Magnesium Alloys: A Critical Review, J. Mater. Eng. Perform., 2013, 22, p 2875–2891

C.W. Tan, B. Chen, X.G. Song, L. Zhou, S.H. Meng, L.Q. Li, and J.C. Feng, Influence of Al Interlayer Thickness on Laser Welding of Mg/Steel, Weld. J., 2016, 95, p 384s–394s

Y. Wei, J. Li, J. Xiong, F. Huang, and F. Zhang, Microstructures and Mechanical Properties of Magnesium Alloy and Stainless Steel Weld-Joint Made by Friction Stir Lap Welding, Mater. Des., 2012, 33, p 111–114

L. Liu, L. Xiao, J.C. Feng, Y.H. Tian, S.Q. Zhou, and Y. Zhou, The Mechanisms of Resistance Spot Welding of Magnesium to Steel, Metall. Mater. Trans. A, 2010, 10, p 2651–2661

L. Liu, L. Xiao, J. Feng, L. Li, S. Esmaeili, and Y. Zhou, Bonding of Immiscible Mg and Fe Via a Nanoscale Fe2Al5 Transition Layer, Scr. Mater., 2011, 65, p 982–985

W. Elthalabawy and T. Khan, Liquid Phase Bonding of 316L Stainless Steel to AZ31 Magnesium Alloy, J. Mater. Sci. Technol., 2011, 27, p 22–28

W.M. Elthalabawy and T.I. Khan, Eutectic Bonding of Austenitic Stainless Steel 316L to Magnesium Alloy AZ31 Using Copper Interlayer, Int. J. Adv. Manuf. Tech., 2010, 55, p 235–241

W.M. Elthalabawy and T.I. Khan, Microstructural Development of Diffusion-Brazed Austenitic Stainless Steel to Magnesium Alloy Using a Nickel Interlayer, Mater. Charact., 2010, 61, p 703–712

R. Cao, J.Y. Yu, J.H. Chen, and P.C. Wang, Feasibility of Cold-Metal-Transfer Welding Magnesium AZ31 to Galvanized Mild Steel, Weld. J., 2013, 92, p 274s–282s

X.Y. Wang, D.Q. Sun, and Y. Sun, Influence of Cu-Interlayer Thickness on Microstructures and Mechanical Properties of MIG-Welded Mg-Steel Joints, J. Mater. Eng. Perform., 2016, 25, p 910–920

L. Liu and X. Qi, Effects of Copper Addition on Microstructure and Strength of the Hybrid Laser-TIG Welded Joints Between Magnesium Alloy and Mild Steel, J. Mater. Sci., 2009, 44, p 5725–5731

L. Liu, X. Qi, and Z. Wu, Microstructural Characteristics of Lap Joint Between Magnesium Alloy and Mild Steel with and Without the Addition of Sn Element, Mater. Lett., 2010, 64, p 89–92

X. Qi and G. Song, Interfacial Structure of the Joints Between Magnesium Alloy and Mild Steel with Nickel as Interlayer by Hybrid Laser-TIG Welding, Mater. Des., 2010, 31, p 605–609

A.M. Nasiri, L. Li, S.H. Kim, Y. Zhou, D.C. Weckman, and T.C. Nguyen, Microstructure and Properties of Laser Brazed Magnesium to Coated Steel, Weld. J., 2011, 90, p 211s–219s

A.M. Nasiri, P. Chartrand, D.C. Weckman, and N.Y. Zhou, Thermochemical Analysis of Phases Formed at the Interface of a Mg Alloy-Ni-Plated Steel Joint During Laser Brazing, Metall. Mater. Trans. A, 2013, 44, p 1937–1946

A.M. Nasiri, D.C. Weckman, and Y. Zhou, Interfacial Microstructure of Diode Laser Brazed AZ31B Magnesium to Steel Sheet Using a Nickel Interlayer, Weld. J., 2013, 92, p 1s–10s

S. Chen, J. Huang, K. Ma, X. Zhao, and A. Vivek, Microstructures and Mechanical Properties of Laser Penetration Welding Joint with/Without Ni-Foil in an Overlap Steel-on-Aluminum Configuration, Metall. Mater. Trans. A, 2014, 45, p 3064–3073

S. Chen, D. Yang, M. Zhang, J. Huang, and X. Zhao, Interaction Between the Growth and Dissolution of Intermetallic Compounds in the Interfacial Reaction Between Solid Iron and Liquid Aluminum, Metall. Mater. Trans. A, 2016, 47, p 5088–5100

S. Chen, Z. Zhai, J. Huang, X. Zhao, and J. Xiong, Interface Microstructure and Fracture Behavior of Single/Dual-Beam Laser Welded Steel-Al Dissimilar Joint Produced with Copper Interlayer, Int. J. Adv. Manuf. Technol., 2016, 82, p 631–643

L. Li, C. Tan, Y. Chen, W. Guo, and X. Hu, Influence of Zn Coating on Interfacial Reactions and Mechanical Properties During Laser Welding-Brazing of Mg to Steel, Metall. Mater. Trans. A, 2012, 43, p 4740–4754

L. Li, C. Tan, Y. Chen, W. Guo, and C. Mei, CO2 Laser Welding-Brazing Characteristics of Dissimilar Metals AZ31B Mg Alloy to Zn Coated Dual Phase Steel with Mg Based Filler, J. Mater. Process. Technol., 2013, 213, p 361–375

C.W. Tan, Y.B. Chen, L.Q. Li, and W. Guo, Comparative Study of Microstructure and Mechanical Properties of Laser Welded–Brazed Mg/Steel Joints with Four Different Coating Surfaces, Sci. Technol. Weld. Joi., 2013, 18, p 466–472

Y. Miao, D. Han, X. Xu, and B. Wu, Phase Constitution in the Interfacial Region of Laser Penetration Brazed Magnesium–Steel Joints, Mater. Charact., 2014, 93, p 87–93

M. Gao, S. Mei, Z. Wang, X. Li, and X. Zeng, Process and Joint Characterizations of Laser–MIG Hybrid Welding of AZ31 Magnesium Alloy, J. Mater. Process. Technol., 2012, 212, p 1338–1346

M.X. Zhang, P.M. Kelly, M. Qian, and J.A. Taylor, Crystallography of Grain Refinement in Mg-Al Based Alloys, Acta Mater., 2005, 53, p 3261–3270

Acknowledgments

The work was financially supported by National Natural Science Foundation of China (Grant No. 51504074), Shandong Provincial Young and Middle Aged Scientists Research Awards Fund (Grant Nos. BS2015ZZ008 and BS2014ZZ002) and China Postdoctoral Science Foundation (Grant Nos. 2015M571406 and 2016T90280).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, C., Xiao, L., Liu, F. et al. Influence of Laser Power on the Microstructure and Mechanical Properties of a Laser Welded-Brazed Mg Alloy/Ni-Coated Steel Dissimilar Joint. J. of Materi Eng and Perform 26, 2983–2997 (2017). https://doi.org/10.1007/s11665-017-2726-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2726-3