Abstract

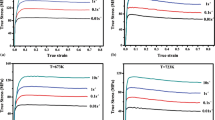

Isothermal uniaxial compression tests were conducted on aluminum alloy AA2219 to study the evolution of microstructure over a wide range of temperatures (300-500 °C) and strain rates (0.001-100 s−1) with a view to study the flow behavior and concurrent microstructural evolution. True stress-true strain curves showed only a gradual flow softening at all temperatures except at 300 °C where strain hardening was followed by severe flow softening. Processing map delineating the stable ‘safe’ and unstable ‘unsafe’ regions during hot working is developed and validated by comparing the microstructures observed in the deformed compression specimens. Optimum processing parameters (temperature 450 °C and strain rate 0.001 s−1) for hot deformation of AA2219 were proposed based on contour maps of efficiency of power dissipation and strain rate sensitivity parameter. The activation energy value (Q avg) of AA2219 for hot working was computed to be 169 kJ/mol. Finally, a constitutive equation for hot working of AA2219 was established as: \(\dot{\varepsilon } = 4.99 \times 10^{9} \cdot \exp (0.06149\sigma ) \cdot \exp \left( { - 168.958/RT} \right)\).

Similar content being viewed by others

References

J. Zhang, B. Chen, and B. Zhang, Effect of Initial Microstructure on the Hot Compression Deformation Behaviour of a 2219 Aluminium Alloy, Mater. Des., 2012, 34, p 15–21

S.G. Pantelakis and N.D. Alexopoulos, Assessment of the Ability of Conventional and Advanced Wrought Aluminium Alloys for Mechanical Performance in Light-Weight Applications, Mater. Des., 2008, 29, p 80–91

N. Nayan, N.P. Gurao, S.V.S. Narayana Murty, A.K. Jha, B. Pant, S.C. Sharma, and K.M. George, Microstructure and Micro-Texture Evolution During Large Strain Deformation of an Aluminium-Copper-Lithium Alloy AA2195, Mater. Des., 2015, 65, p 862–868

H.J. Frost and M.F. Ashby, Deformation Mechanism Maps, The Plasticity and Creep of Metals and Ceramics, Pergamon Press, London, 1982

R. Raj, Development of a Processing Map for Use in Warm Forming and Hot Forming Process, Metall. Trans. A, 1981, 12, p 1089–1097

S.L. Semiatin and G.D. Lahoti, The Occurrence of Shear Bands in Isothermal Hot Forging, Metall. Trans. A, 1992, 13, p 275–288

G.E. Dieter, Metals Hand Book, 9th ed., vol. 14, American Society for Metals, Metals Park, OH, 1988, p 363–372

S.L. Semiatin and J.J. Jonas, Formability and Workability of Metals: Plastic Instability and Flow Localization, American Society for Metals, Metals park, Ohio, 1984

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Material Behaviour in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15A, p 1883–1892

H.L. Gegel, J.C. Malas, S.M. Doraivelu, and V.A. Shende, Modeling Techniques Used In Forging Process Design, Metals Handbook, Forming and Forging, vol. 14, ASM International, Metals Park, OH, 1988, p 417–438

J.M. Alexander, Mapping Dynamic Material Behaviour in Modeling of Hot Deformation of Steels, J.G. Lenard, Ed., Springer, Berlin, 1989, p 101–115

H.J. McQueen, Elevated Temperature Deformation at Forming Rates of 10−2–102 s−1, Metall. Mater. Trans. A, 2002, 33A, p 345–362

R. Kaibyshev, O. Sitdikov, I. Mazurina, and D.R. Leuser, Deformation Behaviour of 2219 Al Alloy, Mater. Sci. Eng. A, 2002, 34, p 104–113

H. Ziegler, Progress in Solid Mechanics, I.N. Sneddon and R. Hill, Ed., Wiley, New York, NY, 1965, p 91–193

S.V.S. Narayana Murty, M.S. Sarma, and B. Nageswara Rao, On the Evaluation of Efficiency Parameter in Processing Maps, Metall. Mater. Trans. A, 1997, 28A, p 1581–1582

S.V.S. Narayana Murty, B. Nageswara Rao, and B.P. Kashyap, Instability Criteria for Hot Deformation of Materials, Int. Mater. Rev., 2000, 45, p 15–26

S.V.S. Narayana Murty and B. Nageswara Rao, Ziegler’s Criterion on the Instability Regions in Processing Maps, J. Mater. Sci. Lett., 1998, 17, p 1203–1205

S.V.S. Narayana Murty and B. Nageswara Rao, On the Dynamic Material Model for the Hot Deformation of Materials, J. Mater. Sci. Lett., 1999, 18, p 1757–1758

S.V.S. Narayana Murty and B. NageswaraRao, On the Development of Instability Criteria During Hot Working with Reference to IN 718, Mater. Sci. Eng. A, 1998, 254, p 76–82

S.V.S. Narayana Murty, B. Nageswara Rao, and B.P. Kashyap, Development and Validation of a Processing Map for AFNOR 7020 Aluminum Alloy, Mater. Sci. Technol., 2004, 20, p 772–782

C.M. Sellars and WJMcG Tegart, Hot Workability, Int. Metall. Rev., 1972, 17, p 1–24 ((Review 158)

J. Jonas, C.M. Sellars, and WJMcG Tegart, Strength and Structure Under Hot-Working Conditions, Metall. Rev., 1972, 14, p 1–24 ((Review 130))

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A, 2002, 322, p 43–63

C. Shi and X.-G. Chen, Evolution of Activation Energies for Hot Deformation of 7150 Aluminum Alloys with Various Zr and V Additions, Mater. Sci. Eng. A, 2016, 650, p 197–209

C. Shi, W. Mao, and X.-G. Chen, Evolution of Activation Energy During Hot Deformation of AA7150 Aluminum Alloy, Mater. Sci. Eng. A, 2013, 571, p 83–91

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater Sci., 2014, 60, p 130–207

R. Kaibyshev, I. Mazurina, and O. Sitdikov, Geometric Dynamic Recrystallization in an AA2219 Alloy Deformed to Large Strains at an Elevated Temperature, Mater. Sci. Forum, 2004, 467–470, p 1199–1204

N. Nayan, N.P. Gurao, S.V.S. Narayana Murty, A.K. Jha, B. Pant, and K.M. George, Microstructure and Micro-Texture Evolution During Large Strain Deformation of Inconel Alloy IN718, Mater. Charact., 2015, 110, p 236–241

E.T. George and D.S. MacKenzie, Ed., Handbook of Aluminium: Volume 2: Alloy Production and Materials Manufacturing, Marcel Dekker Inc., New York, 2003, p 213–214

R. Kaibyshev, I. Kazakulov, D. Gromov, F. Musin, D.R. Leuser, and T.G. Nieh, Superplasticity in a 2219 Alumnium Alloy, Scr. Mater., 2001, 44, p 2411–2417

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15, p 22

T. Sheppard, Ed., Extrusion of Aluminium Alloys, 1st ed., Springer Science+Business Media, Dordrecht, 1999, p 135

K.E. Tello, A.P. Gerlich, and P.F. Mendez, Constants for Hot Deformation Constitutive Models for Recent Experimental Data, Sci. Technol. Weld. Join., 2010, 15, p 260–266

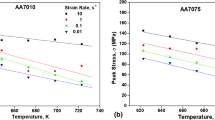

E. Cerri, E. Evangelista, A. Forcellese, and H.J. McQueen, Comparative Hot Workability of 7012 and 7075 Alloys After Different Pre-Treatments, Mater. Sci. Eng. A, 1995, 197, p 181–198

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Narayana Murty, S.V.S., Sarkar, A., Ramesh Narayanan, P. et al. Development of Processing Maps and Constitutive Relationship for Thermomechanical Processing of Aluminum Alloy AA2219. J. of Materi Eng and Perform 26, 2190–2203 (2017). https://doi.org/10.1007/s11665-017-2669-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2669-8