Abstract

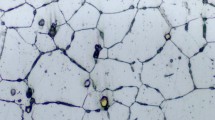

In the present study, corrosion behavior of microwave welded Inconel-718 at various conditions was investigated. Welding of Inconel-718 in 980 °C solution-treated condition was performed using microwave hybrid heating technique. The microwave welds were subjected to post-heat treatment for improving its microstructure and mechanical properties by solubilizing the Nb-enriched Laves phase. The microstructural features of the fabricated welds at various conditions were investigated through scanning electron microscopy. The electrochemical testing results revealed that Inconel-718 welds were galvanic corroded when they were anodically polarized in 3.5 wt.% NaCl solution at 28 °C. The difference in the corrosion potentials between the base metal (BM) and fusion zone (FZ) in an Inconel-718 weld was the main factor for galvanic corrosion. The highest corrosion was occurred in the as-welded/aged weldments, followed by 980 °C solution-treated and aged weldments, as-welded specimen, and 1080 °C solution-treated and aged (1080STA) weldments. The least galvanic corrosion was occurred in the 1080STA specimens due to almost uniform microstructure developed in the weldment after the treatment. Thus, it was possible to minimize the galvanic corrosion in the microwave welded Inconel-718 by 1080STA treatment which resulted in reducing the difference in corrosion potentials between the BM and the FZ.

Similar content being viewed by others

References

J. Prybylowski and R. Ballinger, Influence of Microstructure on the Environmentally Assisted Cracking of Inconel 718, NACE, 1987, 43, p 111–117

O. Ozgun, R. Yilmaz, H.O. Gulsoy, and F. Findik, The Effect of Aging Treatment on the Fracture Toughness and Impact Strength of Injection Moulded Ni-625 Superalloy Parts, Mater. Charact., 2015, 108, p 8–15

O. Ozgun, H.O. Gulsoy, R. Yilmaz, and F. Findik, Injection Molding of Nickel Based 625 Superalloy: Sintering, Heat Treatment, Microstructure and Mechanical Properties, J. Alloys Compd., 2013, 546, p 192–207

O. Ozgun, H.O. Gulsoy, F. Findik, and R. Yilmaz, Microstructure and Mechanical properties of Injection Moulded Nimonic-90 Superalloy parts, Powder Metall., 2012, 55, p 405–414

L. Nastac and D.M. Stefanescu, Macrotransport-Solidification Kinetics Modeling of Equiaxed Dendritic Growth: Part II. Computation Problems and Validation on Inconel 718 Superalloy Castings, Metall. Mater. Trans. A, 1996, 27, p 4075–4083

S. Srinivas and M.C. Pandey, Assessment of Microstructure in the Segregated Region of the Nickel-Base Superalloy 718 Using Various Etchants, Prakt Metallogr-Pr M, 1995, 32, p 143–152

S. Gobbi, L. Zhang, J. Norris, K.H. Richter, and J.H. Loreau, High Power Co2 and Nd-YAG Laser Welding of Wrought Inconel 718, J. Mater. Process. Technol., 1996, 56, p 333–345

X. Huang, M.C. Chaturvedi, N.L. Richards, and J. Jackman, The Effect of Grain Boundary Segregation of Boron in Cast Alloy 718 on HAZ Microfissuring—A Sims Analysis, Acta Metall., 1997, 45, p 3095–3107

C.A. Huang, T.H. Wang, C.H. Lee, and W.C. Han, A Study of the Heat-Affected Zone (HAZ) of an Inconel 718 Sheet Welded with Electron-Beam Welding (EBW), Mater. Sci. Eng. A, 2007, 398, p 275–281

C.A. Huang, Y.C. Chen, and J.H. Chang, The Electrochemical Polishing Behavior of the Inconel 718 alloy in Perchloric–Acetic Mixed Acids, Corros. Sci., 2007, 50, p 480–489

C.A. Huang, T.H. Wang, W.C. Han, and C.H. Lee, A Study of the Galvanic Corrosion Behaviour of Inconel 718 After Electron Beam Welding, Mater. Chem. Phys., 2007, 104, p 293–300

A. Bansal, A.K. Sharma, P. Kumar, and S. Das, On Microstructural and Strength Characterisation of Microwave Welded Inconel 718 Joints at 2.45 GHz Frequency, Kov. Mater., 2015, 53, p 1–9

A. Bansal, A.K. Sharma, P. Kumar, and S. Das, Characterization of Bulk Stainless Steel Joints Developed through Microwave Hybrid Heating, Mater. Charact., 2014, 91, p 34–41

X. Cao, B. Rivaux, M. Jahazi, J. Cuddy, and A. Birur, Effect of Pre and Post-weld Heat Treatment on Metallurgical and Tensile Properties of Inconel 718 Alloy Butt Joints Welded Using 4 kW Nd:YAG Laser, J. Mater. Sci., 2009, 44, p 4557–4571

G.D.J. Ram, A.V. Reddy, K.P. Rao, G.M. Reddy, and J.K.S. Sundar, Microstructure and Tensile Properties of Inconel 718 Pulsed Nd-YAG Laser Welds, J. Mater. Process. Technol., 2005, 167, p 73–82

C. Radhakrishna and K.P. Rao, Effect of Heat Input on Microstructural Changes in Superalloy 718 Welds, Prakt Metallogr-Pr M, 1995, 32, p 506–512

O. Ozgun, H.O. Gulsoy, R. Yilmaz, and F. Findik, Microstructural and Mechanical Characterization of Injection Molded 718 Superalloy Powders, J. Alloys Compd., 2013, 576, p 140–153

C.H. Radhakrishna and K.P. Rao, The Formation and Control of Laves Phase in Superalloy 718 Welds, J. Mater. Sci., 1997, 32, p 1977–1984

T. Hemmingsen, H. Hovdan, P. Sanni, and N.O. Aagotnes, The Influence of Electrolyte Reduction Potential on Weld Corrosion, Electrochim. Acta, 2002, 47, p 3949–3955

L. Tan, X. Ren, K. Sridharan, and T.R. Allen, Corrosion Behavior of Ni-Base Alloys for Advanced High Temperature Water-Cooled Nuclear Plants, Corros. Sci., 2008, 50, p 3056–3062

Acknowledgment

The authors would like to express gratefulness to the Board of Research of Nuclear Sciences (BRNS), India, for financing this work with Project No. 2010/36/60-BRNS/2048.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bansal, A., Sharma, A.K. & Kumar, P. Galvanic Corrosion Behavior of Microwave Welded and Post-weld Heat-Treated Inconel-718 Joints. J. of Materi Eng and Perform 26, 2322–2330 (2017). https://doi.org/10.1007/s11665-017-2665-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2665-z