Abstract

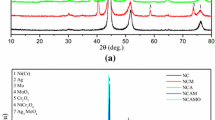

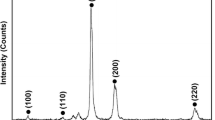

In order to analyze the effects of friction layer thickness on the tribological performance of Ni3Al matrix self-lubricating composites containing Ag and MoO3 tabular crystals (Ni3Al-Ag-MoO3), the dry sliding tribological tests of Ni3Al-Ag-MoO3 against Si3N4 ball are undertaken under 4-16 N and 20-800 °C at 0.2 m/s. The results show that the friction layer thickness of Ni3Al-Ag-MoO3 is obviously affected by the applied loads and ambient temperatures. At 12 N-400 °C-0.2 m/s, Ni3Al-Ag-MoO3 exhibits excellent tribological performance, and the friction layer thickness obtained the maximum value of about 5 µm. Moreover, the simulation results, which based on the building of finite element models with different thickness of the friction layer, indicate that the decreased degree of the maximum equivalent stress in the substrate of Ni3Al-Ag-MoO3 with maximum thickness of friction layer is the larger one (about 39%), if compared to other thickness. It could avoid the generation of cracks and the spalling of subsurface materials during the dry sliding process, resulting in the excellent tribological performance. The results could be used to guide the selection of suitable working conditions and study the self-lubricating mechanisms of Ni3Al-Ag-MoO3 for having stable friction layer structure and excellent antifriction and antiwear performance.

Similar content being viewed by others

References

W.Z. Zhai, X.L. Shi, Z.S. Xu, and Q.X. Zhang, Formation of Friction Layer of Ni3Al Matrix Composites with Micro- and Nano-structure During Sliding Friction Under Different Loads, Mater. Chem. Phys., 2014, 147(3), p 850–859

J. Yao, X.L. Shi, W.Z. Zhai, Z.S. Xu, A.M.M. Ibrahim, Q.S. Zhu, Y.C. Xiao, L. Chen, and Q.X. Zhang, Influence of Lubricants on Wear and Self-Lubricating Mechanisms of Ni3Al Matrix Self-Lubricating Composites, J. Mater. Eng. Perform., 2015, 24(1), p 280–295

H. Nakae, H. Fujii, K. Nakajima, and A. Goto, Infiltration and Combustion Synthesis of an Intermetallic Compound Ni3Al, Mater. Sci. Eng. A, 1997, 223(1), p 21–28

B. Huang, W.H. Xiong, Q.Q. Yang, Z.H. Yao, and G.P. Zhang, Preparation, Microstructure and Mechanical Properties of Multicomponent Ni3Al-Bonded Cermets, Ceram. Int., 2014, 40(9), p 14073–14081

W.Z. Zhai, X.L. Shi, S.Y. Song, J. Yao, A.M.M. Ibrahim, Z.S. Xu, A.Q. Din, L. Cheng, Q.S. Zhu, Y.C. Xiao, and Q.X. Zhang, Tribological Performance of Ni3Al Self-Lubricating Composites with Different Content of TiC at Elevated Temperature, Tribol. Trans., 2015, 58(2), p 365–373

W.Z. Zhai, X.L. Shi, J. Yao, Z.S. Xu, A.M.M. Ibrahim, Q.S. Zhu, L. Chen, and Y.C. Xiao, Synergetic Lubricating Effect of WS2 and Ti3SiC2 on Tribological Properties of Ni3Al Matrix Composites at Elevated Temperatures, Tribol. Trans., 2015, 58(3), p 454–466

Q.S. Zhu, X.L. Shi, W.Z. Zhai, K. Yang, A.M.M. Ibrahim, Z.S. Xu, L. Chen, Y.C. Xiao, A. Zhang, and Q.X. Zhang, Influence of Subsurface Micro/Nano-structural Evolution on Macroscopic Tribological Behavior of Ni3Al Matrix Composites, Tribol. Lett., 2015, 57(3), p 1–13

A. Zhang, X.L. Shi, W.Z. Zhai, K. Yang, and Z.H. Wang, Tribological Behavior of TiAl Matrix Composites with MoO3 Tabular Crystal, J. Mater. Eng. Perform., 2015, 24(11), p 4482–4487

R. Tyagi, D.S. Xiong, J.L. Li, and J.H. Dai, Elevated Temperature Tribological Behavior of Ni Based Composites Containing Nano-silver and hBN, Wear, 2010, 269(11–12), p 884–890

D.S. Xiong and J.L. Li, Friction Wear and Lubrication at High Temperature, Northwestern Polytechnical University Press, Xi’an, 2013

K. Yang, X.L. Shi, D. Zheng, W.Z. Zhai, A.M.M. Ibrahim, and Z.H. Wang, Tribological Behavior of a TiAl Matrix Composite Containing 10 wt% Ag Investigated at Four Wear Stages, RSC Adv., 2015, 5(95), p 77885–77896

L.Y. Yang, Y.J. Wang, and Z.M. Liu, Wear Model of Ti-Al Alloys as Self-lubricating Materials at High-Temperature, Chin. Mech. Eng., 2008, 19(5), p 602–605

F. Xie and Z.M. Liu, Study on Contact Strength of Thick-Walled Cellular Structures, Acta Mech. Solid Sin., 2010, 31(3), p 296–301

W.Z. Zhai, X.L. Shi, Z.S. Xu, and A. Zhang, Investigation of the Friction Layer of Ni3Al Matrix Composites, Wear, 2015, 328–329, p 39–49

F. Peter, Z. Weiss, and D. Rafaja, On Friction Layer Formation in Polymer Matrix Composite Materials for Brake Applications, Wear, 2002, 252(3), p 189–198

Y.C. Xiao, X.L. Shi, W.Z. Zhai, K. Yang, and J. Yao, Effect of Temperature on Tribological Properties and Wear Mechanisms of NiAl Matrix Self-Lubricating Composites Containing Graphene Nanoplatelets, Tribol. Trans., 2015, 58(4), p 729–735

M. Chhowalla and G.A. Maratunga, Thin Films of Fullerene-like MoS2 Nanoparticles with Ultra-Low Friction and Wear, Nature, 2000, 407(6801), p 164–167

Z.S. Xu, Q.X. Zhang, X.J. Huang, R. Liu, W.Z. Zhai, K. Yang, and Q.S. Zhu, An Approximate Model for the Migration of Solid Lubricant on Metal Matrix Self-Lubricating Composites, Tribol. Int., 2016, 93, p 104–114

Y.Z. Wang, P. Huang, and Z.L. Gong, Study on the Influence of Temperature on Interfacial Micro-friction, Acta. Phys. Sin., 2010, 11(10), p 794–803

Z.J. Zhou, Z.F. Yang, Z.G. Xiao, X.X. Luo, and L. Jin, Mechanical Properties and Reliability of Y-TZP/Platelet-Alumina Composites by Templated Grain Growth, Acta Mater. Compos. Sin., 2004, 21(1), p 28–32

J.H. Wang, J.P. Zheng, J.C. Liu, and D.H. Huang, Mechanical Properties of Materials, Tianjin University Press, Tianjin, 2006

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51275370); Self-determined and Innovative Research Funds of WUT (135204008); and the Fundamental Research Funds for the Central Universities (2017-YB-019 and 2016-zy-014); authors were grateful to Y.M. Li, X.L. Nie, M.J. Yang, S.L. Zhao and W.T. Zhu in Material Research and Test Center of WUT for their kind help with EPMA and FESEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, Y., Shi, X., Yang, K. et al. Effects of Friction Layer Thickness on the Tribological Performance of Ni3Al-Ag-MoO3 . J. of Materi Eng and Perform 26, 2313–2321 (2017). https://doi.org/10.1007/s11665-017-2661-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2661-3