Abstract

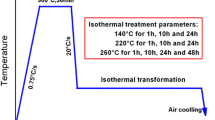

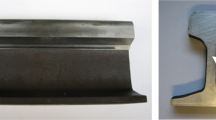

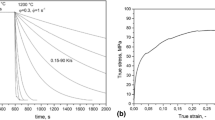

The effects of isothermal treatment on the microstructure and hardness of commercial super-bainitic steel were investigated. A series of isothermal treatments were carried out at temperatures of 210-250 °C for different time periods. The results indicate that the bainitic reaction and hardness were very sensitive to the isothermal transformation temperature. The fine super-bainitic microstructure, containing the carbide-free bainitic ferrite lath and the carbon-enriched retained austenite film, can be produced by heating to 210 °C for 30 h, resulting in a hardness of 662 HV. By increasing the isothermal transformation temperature, the bainitic transformation kinetic is accelerated; however, this is at the expense of coarsening bainitic ferrite laths and decreasing the bainitic ferrite quantity. The relationship between hardness and microstructures obtained under different isothermal treatments, which is correlated with the carbon concentration, dislocation density, bainitic amount and super-bainite size, is discussed in detail.

Similar content being viewed by others

References

H.K.D.H. Bhadeshia, Bainite in Steels, IOM Commercial Ltd., London, 2001

C. Garcia-Mateo, F.G. Caballero, and H.K.D.H. Bhadeshia, Development of Hard Bainite, ISIJ Int., 2003, 43, p 1238–1243

F.G. Caballero and H.K.D.H. Bhadeshia, Very Strong Bainite, Curr. Opin. Solid State Mater. Sci., 2004, 8, p 251–257

M.N. Yoozbashi, S. Yazdani, and T.S. Wang, Design of a New Nanostructured, High-Si Bainitic Steel with Lower Cost Production, Mater. Des., 2011, 32, p 3248–3253

F.G. Caballero, M.K. Miller, and C. Garcia-Mateo, Carbon Supersaturation of Ferrite in a Nanocrystalline Bainitic Steel, Acta Mater., 2010, 58, p 2338–2343

H. Huang, M.Y. Sherif, and P.E.J. Rivera-Diaz-Castillo, Combinatorial Optimization of Carbide-Free Bainitic Nanostructures, Acta Mater., 2013, 61, p 1639–1647

Y. Han, H. Wu, C. Liu, and Y.X. Liu, Microstructures and Mechanical Characteristics of a Medium Carbon Super-Bainitic Steel After Isothermal Transformation, JMEPEG, 2014, 23, p 4230–4236

L. Qian, Q. Zhou, F.C. Zhang, J.Y. Meng, M. Zhang, and Y. Tian, Microstructure and Mechanical Properties of a Low Carbon Carbide-Free Bainitic Steel Co-alloyed with Al and Si, Mater. Des., 2012, 39, p 264–268

X.Y. Long, F.C. Zhang, J. Kang, B. Lv, and B. Shi, Low-Temperature Bainite in Low-Carbon Steel, Mater. Sci. Eng. A, 2014, 594, p 344–351

J. Chakraborty, D. Bhattacharjee, and I. Manna, Austempering of Bearing Steel for Improved Mechanical Properties, Script Mater., 2008, 59, p 247–250

P. Pointner, High Strength Rail Steels—The Importance of Material Properties in Contact Mechanics Problems, Wear, 2008, 265, p 1373–1379

X.Y. Long, J. Kang, B. Lv, and F.C. Zhang, Carbide-Free Bainite in Medium Carbon Steel, Mater. Des., 2014, 64, p 237–245

B. Avishan, C. Garcia-Mateo, S. Yazdani, and F.G. Caballero, Retained Austenite Thermal Stability in a Nanostructured Bainitic Steel, Mater. Charat., 2013, 81, p 105–110

G. Xu, F. Liu, L. Wang, and H.J. Hu, A New Approach to Quantitative Analysis of Bainitic Transformation in a Superbainite Steel, Srcipta Mater., 2013, 68, p 833–836

F. Hu, P.D. Hodgson, and K.M. Wu, Acceleration of the Super Bainite Transformation Through a Coarse Austenite Grain Size, Mater. Let., 2014, 122, p 240–243

C. Garcia-Mateo, F.G. Caballero, and H.K.D.H. Bhadeshia, Mechanical Properties of Low-Temperature Bainite, Mater. Sci. Forum, 2005, 500-501, p 495–502

M.N. Yoozbashi and S. Yazdani, Mechanical Properties of Nanostructured, Low Temperature Bainitic Steel Designed Using a Thermodynamic Model, Mater. Sci. Eng. A, 2010, 527, p 3200–3205

F.G. Caballero, H.K.D.H. Bhadeshia, K.J.A. Mawella, D.G. Jones, and P. Brown, Design of Novel High Strength Bainitic Steel: Part 2, Mater. Sci. Technol., 2001, 17, p 517–522

C. Garcia-Mateo, F.G. Caballero, and H.K.D.H. Bhadeshia, Acceleration of Low-temperature Bainite, ISIJ Int., 2003, 43, p 1821–1825

H. Amel-Farzad, H.R. Faridi, F. Rajabpour, A. Abolhasani, S. Kazemi, and Y. Khaledzadeh, Developing Very Hard Nanostructured Bainitic Steel, Mater. Sci. Eng., A, 2013, 559, p 68–73

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 51171030 and 51604034), the Scientific and Technological Planning Project of Jilin Province (No. 20150520030JH) and the Scientific and Technological Research Fund of Jilin Provincial Education Department during the Twelfth Five-year Plan Period (No. 2015-95).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, Y., Xiu, W., Liu, C. et al. Isothermal Transformation of a Commercial Super-Bainitic Steel: Part I Microstructural Characterization and Hardness. J. of Materi Eng and Perform 26, 472–477 (2017). https://doi.org/10.1007/s11665-016-2473-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2473-x