Abstract

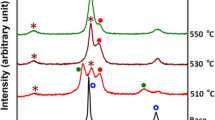

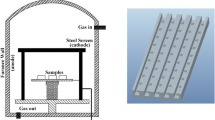

Plasma source nitriding is a relatively new nitriding technology which can overcome those inherent shortcomings associated with conventional direct current plasma nitriding technology such as the arcing surface damage, the edging effect and the hollow cathode effect. There is considerable study on the properties of nitrided samples for laboratorial scale plasma source nitriding system; however, little information has been reported on the industrial-scale plasma source nitriding system. In this work, AISI 316 austenitic stainless steel samples were nitrided by an industrial-scale plasma source nitriding system at various nitriding temperatures (350, 400, 450 and 500 °C) with a floating potential. A high-nitrogen face-centered-cubic phase (γN) formed on the surface of nitrided sample surface. As the nitriding temperature was increased, the γN phase layer thickness increased, varying from 1.5 μm for the lowest nitriding temperature of 350 °C, to 30 μm for the highest nitriding temperature of 500 °C. The maximum Vickers microhardness of the γN phase layer with a peak nitrogen concentration of 20 at.% is about HV 0.1 N 15.1 GPa at the nitriding temperature of 450 °C. The wear and corrosion experimental results demonstrated that the γN phase was formed on the surface of AISI 316 austenitic stainless steel by plasma source nitriding, which exhibits not only high wear resistance, but also good pitting corrosion resistance.

Similar content being viewed by others

References

Z.L. Zhang and T. Bell, Structure and Corrosion Resistance of Plasma Nitrided Stainless Steel, Surf. Eng., 1985, 1, p 131–136

T. Bell, Y. Sun, and A. Suhadi, Environmental and Technical Aspects of Plasma Nitrocarburising, Vacuum, 2000, 59, p 14–23

M.K. Lei and Z.L. Zhang, Plasma Source Ion Nitriding: A New Low-Temperature, Low-Pressure Nitriding Approach, J. Vac. Sci. Technol., 1995, 13, p 2986–2990

V. Singh, K. Marchev, C.V. Cooper, and E.I. Meletis, Intensified Plasma-Assisted Nitriding of AISI, 316L Stainless Steel, Surf. Coat. Technol., 2002, 160, p 249–258

C.X. Li, T. Bell, and H. Dong, A Study of Active Screen Plasma Nitriding, Surf. Eng., 2002, 18, p 174–181

R. Hugon, G. Henrion, and M. Fabry, Diagnostics of a DC Pulsed-Plasma-Assisted Nitriding Process, Surf. Coat. Technol., 1993, 59, p 82–85

G.Y. Li, Z.Y. Wang, and M.K. Lei, Transition of Wear Mechanisms of Plasma Source Nitrided AISI, 316 Austenitic Stainless Steel Against Ceramic Counterface, ASME J. Tribol., 2012, 134, p 011601–011609

C. Alves, Jr., F.O. de Araujo, K.J.B. Ribeiro, J.A.P. da Costa, R.R.M. Sousa, and R.S. de Sousa, Use of Cathodic Cage in Plasma Nitriding, Surf. Coat. Technol., 2006, 201, p 2450–2454

C. Zhao, C.X. Li, H. Dong, and T. Bell, Study on the Active Screen Plasma Nitriding and Its Nitriding Mechanism, Surf. Coat. Technol., 2006, 201, p 2320–2325

A. Nishimoto, K. Nagatsuka, R. Narita, H. Nii, and K. Akamatsu, Effect of the Distance Between Screen and Sample on Active Screen Plasma Nitriding Properties, Surf. Coat. Technol., 2010, 205, p 365–368

J. Georges and D. Cleugh, Active Screen Plasma Nitriding, Stainless Steel 2000: Thermochemical Surface Engineering of Stainless Steel, T. Bell and K. Akamatsu, Ed., Maney Publishing, Leeds, 2001, p 377–387

Y. Sun, T. Bell, Z. Kolosvary, and J. Flis, The Response of Austenitic Stainless Steels to Low-Temperature Plasma Nitriding, Heat Treat. Met., 1999, 26, p 9–16

N. Yasumaru, Low-Temperature Ion Nitriding of Austenitic Stainless Steels, Mater. Trans., 1998, 39, p 1046–1052

M.K. Lei and Z.L. Zhang, Microstructure and Corrosion Resistance of Plasma Source Ion Nitrided Austenitic Stainless Steel, J. Vac. Sci. Technol. A, 1997, 15, p 421–427

Y. Sun, X.Y. Li, and T. Bell, X-ray Diffraction Characterisation of Low Temperature Plasma Nitrided Austenitic Stainless Steels, J. Mater. Sci., 1998, 34, p 4793–4802

M.K. Lei and J. Liang, X-ray Diffraction of High Nitrogen Face Centred Cubic Phase Formed on Nitrogen Modified Austenitic Stainless Steel, Surf. Eng., 2010, 26, p 305–311

J. Oddershede, T.L. Christiansen, and M.A.J. Somers, Extended X-ray Absorption Fine Structure Investigation of Nitrogen Stabilized Expanded Austenite, Scripta Mater., 2004, 62, p 290–293

M.K. Lei, Phase Transformations in Plasma Source Ion Nitrided Austenitic Stainless Steel at Low Temperature, J. Mater. Sci., 1999, 34, p 5975–5982

C.X. Li and T. Bell, Sliding Wear Properties of Active Screen Plasma Nitrided 316 Austenitic Stainless Steel, Wear, 2004, 256, p 1144–1152

M.K. Lei and X.M. Zhu, Plasma-Based Low-Energy Ion Implantation Of Austenitic Stainless Steel for Improvement in Wear and Corrosion Resistance, Surf. Coat. Technol., 2005, 193, p 22–28

M.K. Lei, Q. Zhou, Y.X. Ou, T.K. Song, and Y. Guo, Tribological Behaviour of Plasma Based Low Energy Nitrogen Ion Implanted AISI 316 Austenitic Stainless Steel Against Same Stainless Steel Counterface, Surf. Eng., 2010, 26, p 277–283

M.K. Lei and X.M. Zhu, Role of Nitrogen in Pitting Corrosion Resistance of a High-Nitrogen Face-Centered-Cubic Phase Formed on Austenitic Stainless Steel, J. Electrochem. Soc., 2005, 152, p B291–B295

M.K. Lei and X.M. Zhu, Comparative Corrosion Resistance of Plasma-Based Low-Energy Nitrogen Ion Implanted Austenitic Stainless Steel, Surf. Coat. Technol., 2007, 201, p 6865–6868

Acknowledgments

The authors are very grateful to Professor X.M. Zhu, Mrs. L.J. Yuan and Mr. F.Q. Liu for their contributory discussions and technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, G.Y., Lei, M.K. Microstructure and Properties of Plasma Source Nitrided AISI 316 Austenitic Stainless Steel. J. of Materi Eng and Perform 26, 418–423 (2017). https://doi.org/10.1007/s11665-016-2435-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2435-3