Abstract

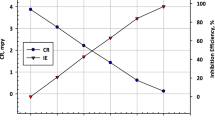

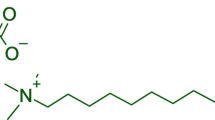

Microbiologically influenced corrosion (MIC) of carbon steel infrastructure is an emerging environmental and cost issue for the ethanol fuel industry, yet its examination lacks rigorous quantification of microbiological parameters that could reveal effective intervention strategies. To quantitatively characterize the effect of cell concentration on MIC of carbon steel, numbers of bacteria exposed to test coupons were systematically controlled to span four orders of magnitude throughout a seven-day test. The bacterium studied, Acetobacter aceti, has been found in ethanol fuel environments and can convert ethanol to the corrosive species acetic acid. A. aceti biofilms formed during the test were qualitatively evaluated with fluorescence microscopy, and steel surfaces were characterized by scanning electron microscopy. During exposure, biofilms developed more quickly, and test reactor pH decreased at a faster rate, when cell exposure was higher. Resulting corrosion rates, however, were inversely proportional to cell exposure, indicating that A. aceti biofilms are able to protect carbon steel surfaces from corrosion. This is a novel demonstration of corrosion inhibition by an acid-producing bacterium that occurs naturally in corrosive environments. Mitigation techniques for MIC that harness the power of microbial communities have the potential to be scalable, inexpensive, and green solutions to industrial problems.

Similar content being viewed by others

Notes

Commercial equipment, instruments, or materials are identified only in order to adequately specify certain procedures. In no case does such identification imply recommendation or endorsement by the National Institute of Standards and Technology, nor does, it imply that the products identified are necessarily the best available for the purpose.

References

R. Javaherdashti, Microbiologically Influenced Corrosion: An Engineering Insight, Springer, London, 2008

National Research Council, Committee for Assessment of Corrosion Education. The National Academies, Washington, DC, 2009, p. 12

G.H. Koch, M.P.H. Brongers, N.G. Thompson, and Y.P. Virmani, Corrosion Costs and Preventive Strategies in the United States, U.S. Department of Transportation, Washington DC, 2002

B. Little and J. Lee, Microbiologically Influenced Corrosion, Wiley, Hoboken, 2007

J. Lin and R. Ballim, Biocorrosion Control: Current Strategies and Promising Alternatives, Afr. J. Biotechnol., 2012, 11(91), p 15736–15747

L. Jain, C. Williamson, S.M. Bhola, R. Bhola, J.R. Spear, B. Mishra, D.L. Olson, and R.D. Kane, Microbiological and Electrochemical Evaluation of Corrosion and Microbiologically Influenced Corrosion of Steel in Ethanol Fuel Environments, CORROSION 2010, Paper No. 10070, NACE International, Houston, TX, 2010

R.D. Kane, J.G. Maldonado, and L.J. Klein, Stress Corrosion Cracking in Fuel Ethanol: A Newly Recognized Phenomenon, CORROSION 2004, Paper No. 04543, NACE International, Houston, TX, 2004

S. Jain, Ethanol-Water Phase Separation. What It is—And What You can Do. PEI J. (Fourth Quarter), 2010, p 48–54

S.M. Bhola, R. Bhola, L. Jain, B. Mishra, and D.L. Olson, Corrosion Behavior of Mild Carbon Steel in Ethanolic Solutions, JMEPEG, 2011, 20, p 409–416

Renewable.Fuels. Association, B.D. Falling Walls, and Rising. Tides, Ethanol Industry Outlook, Renewable Fuels Association, Washington, DC, 2014

C.-G. Peng and J.K. Park, Principal Factors Affecting Microbiologically Influenced Corrosion of Carbon Steel, Corros. Sci., 1994, 50(9), p 669–675

H.H. Almahamedh, J.R. Spear, D.L. Olson, C. Williamson, and B. Mishra, Identification of Microorganisms and Their Effects on Corrosion of Carbon Steel Pipelines, CORROSION 2011, Paper No. 11231, NACE International, Houston, TX, 2011

M. Morikawa, Beneficial Biofilm Formation by Industrial Bacteria Bacillus subtilis and Related Species, J. Biosci. Bioeng., 2006, 101(1), p 1–8

M.D. Ghafari, A. Bahrami, I. Rasooli, D. Arabian, and F. Ghafari, Bacterial Exopolymeric Inhibition of Carbon Steel Corrosion, Int. Biodeterior. Biodegrad., 2013, 80, p 29–33

B. Little, J. Lee, and R. Ray, A Review of ‘Green’ Strategies to Prevent or Mitigate Microbiologically Influenced Corrosion, Biofouling, 2007, 23(1-2), p 87–97

M. Dubiel, C.H. Hsu, C.C. Chien, F. Mansfeld, and D.K. Newman, Microbial Iron Respiration can Protect Steel from Corrosion, Appl. Environ. Microbiol., 2002, 68(3), p 1440–1445

A.K. Lee and D.K. Newman, Microbial Iron Respiration: Impacts on Corrosion Processes, Appl. Microbiol. Biotechnol., 2003, 62(2-3), p 134–139

A.K. Lee, M.G. Buehler, and D.K. Newman, Influence of a Dual-Species Biofilm on the Corrosion of Mild Steel, Corros. Sci., 2006, 48(1), p 165–178

F.M. AlAbbas, S.M. Bhola, J.R. Spear, D.L. Olson, and B. Mishra, The Shielding Effect of Wild Type Iron Reducing Bacterial Flora on the Corrosion of Linepipe Steel, Eng. Fail. Anal., 2013, 33, p 222–235

A. Jayaraman, E.T. Cheng, J.C. Earthman, and T.K. Wood, Importance of Biofilm Formation for Corrosion Inhibition of SAE 1018 Steel by Axenic Aerobic Biofilms, J. Ind. Microbiol. Biotechnol., 1997, 18, p 396–401

A. Jayaraman, J.C. Earthman, and T.K. Wood, Corrosion Inhibition by Aerobic Biofilms on SAE 1018 Steel, Appl. Microbiol. Biotechnol., 1997, 47, p 62–68

A. Jayaraman, A.K. Sun, and T.K. Wood, Characterization of Axenic Pseudomonas fragi and Escherichia coli Biofilms that Inhibit Corrosion of SAE 1018 Steel, J. Appl. Microbiol., 1998, 84, p 485–492

K.M. Ismail, T. Gehrig, A. Jayaraman, T.K. Wood, K. Trandem, P.J. Arps, and J.C. Earthman, Corrosion Control of Mild Steel by Aerobic Bacteria Under Continuous Flow Conditions, Corrosion, 2002, 58(5), p 417–423

B. Little and R. Ray, A Perspective on Corrosion Inhibition by Biofilms, Corrosion, 2002, 58(5), p 424–428

R. Zuo, Biofilms: Strategies for Metal Corrosion Inhibition Employing Microorganisms, Appl. Microbiol. Biotechnol., 2007, 76(6), p 1245–1253

H.A. Videla and L.K. Herrera, Understanding Microbial Inhibition of Corrosion. A Comprehensive Overview, Int. Biodeterior. Biodegrad., 2009, 63(7), p 896–900

A. Jayaraman, E.T. Cheng, J.C. Earthman, and T.K. Wood, Axenic Aerobic Biofilms Inhibit Corrosion of SAE 1018 Steel Through Oxygen Depletion, Appl. Microbiol. Biotechnol., 1997, 48, p 11–17

J.S. Potekhina, N.G. Sherisheva, L.P. Povetkina, A.P. Pospelov, T.A. Rakitina, F. Warnecke, and G. Gottschalk, Role of Microorganisms in Corrosion Inhibition of Metals in Aquatic Habitats, Appl. Microbiol. Biotechnol., 1999, 52, p 639–646

R. Zuo, E. Kus, F. Mansfeld, and T.K. Wood, The Importance of Live Biofilms in Corrosion Protection, Corros. Sci., 2005, 47(2), p 279–287

Z. Lewandowski and H. Beyenal, Mechanisms of Microbially Influenced Corrosion, Marine and Industrial Biofouling, Vol 4, H.-C. Flemming, P.S. Murthy, R. Venkatesan, and K.E. Cooksey, Ed., Springer, Berlin, 2008, p 35–64

R. Zuo and T.K. Wood, Inhibiting Mild Steel Corrosion from Sulfate-Reducing and Iron-Oxidizing Bacteria Using Gramicidin-S-Producing Biofilms, Appl. Microbiol. Biotechnol., 2004, 65(6), p 747–753

C. Williamson, An Investigation of Microbial Diversity and Microbiologically Influenced Corrosion in Automotive Fuel Environments, Colorado School of Mines, Golden, 2012

K. Matsushita, T. Inoue, O. Adachi, and H. Toyama, Acetobacter aceti Possesses a Proton Motive Force-Dependent Efflux System for Acetic Acid, J. Bacteriol., 2005, 187(13), p 4346–4352

K. Sakurai, H. Arai, M. Ishii, and Y. Igarashi, Transcriptome Response to Different Carbon Sources in Acetobacter aceti, Microbiology, 2011, 157, p 899–910

J.W. Sowards, T.D. Weeks, J.D. McColskey, J.R. Fekete, C. Williamson, and L. Jain, Effect of Ethanol Fuel and Microbiologically Influenced Corrosion on the Fatigue Crack Growth Behavior of Pipeline Steels, DoD Corrosion Conference 2011, NACE International, La Quinta, 2011.

J.W. Sowards and E. Mansfield, Corrosion of Copper and Steel Alloys in a Simulated Underground Storage-Tank Sump Environment Containing Acid-Producing Bacteria, Corros. Sci., 2014, 87, p 460–471

V. Reipa, J. Almeida, and K.D. Cole, Long-Term Monitoring of Biofilm Growth and Disinfection Using a Quartz Crystal Microbalance and Reflectance Measurements, J. Microbiol. Methods, 2006, 66(3), p 449–459

A.M. de Roda Husman, W.J. Lodder, S.A. Rutjes, J.F. Schijven, and P.F.M. Teunis, Long Term Inactivation Study of Three Enteroviruses in Artificial Surface and Groundwaters, Using PCR and Cell Culture, Appl. Environ. Microbiol., 2009, 75(4), p 1050–1057

W.S. Rasband, ImageJ, National Institutes of Health, Bethesda, 1997–2014

D.J. Lane, 16S/23S rRNA Sequencing, Nucleic Acid Techniques in Bacterial Systematics, E. Stackebrandt and M. Goodfellow, Ed., Wiley, New York, 1991, p 115–175

Y. Yu, C. Lee, J. Kim, and S. Hwang, Group-Specific Primer and Probe Sets to Detect Methanogenic Communities Using Quantitative Real-Time Polymerase Chain Reaction, Biotechnol. Bioeng., 2005, 89, p 670–679

J.R. Cole, Q. Wang, J.A. Fish, B. Chai, D.M. McGarrell, Y. Sun, C.T. Brown, A. Porras-Alfaro, C.R. Kuske, and J.M. Tiedje, Ribosomal Database Project: Data and Tools for High Throughput rRNA Analysis. Nucl. Acids Res., 41(Database issue), p D633–D642

ASTM International, ASTM Standard G31-72, 2004, Standard Practice for Laboratory Immersion Corrosion Testing of Metals, ASTM International, West Conshohocken, 2004

The Dow Chemical Company, Glutaraldehyde: An Effective Broad Spectrum Biocide, International Hatchery Practice Magazine, 2005, p 10

S.E. Walsh, J.-Y. Maillard, and A.D. Russell, Ortho-phthalaldehyde: A Possible Alternative to Glutaraldehyde for High-Level Disinfection, J. Appl. Microbiol., 1999, 86, p 1039–1046

X. Lou and P.M. Singh, Role of Water, Acetic acid and Chloride on Corrosion and Pitting Behaviour of Carbon Steel in Fuel-Grade Ethanol, Corros. Sci., 2010, 52, p 2303–2315

J.W. Costerton, Z. Lewandowski, D. DeBeer, D. Caldwell, D. Korber, and G. James, Biofilms, The Customized Microniche, J. Bacteriol., 1994, 176(8), p 2137–2142

G. Hidalgo, A. Burns, E. Herz, A.G. Hay, P.L. Houston, U. Wiesner, and L.W. Lion, Functional Tomographic Fluorescence Imaging of pH Microenvironments in Microbial Biofilms by Use of Silica Nanoparticle Sensors, Appl. Environ. Microbiol., 2009, 75(23), p 7426–7435

S. Schlafer, M.K. Raarup, R.L. Meyer, D.S. Sutherland, I. Dige, J.R. Nyengaard, and B. Nyvad, pH Landscapes in a Novel Five-Species Model of Early Dental Biofilm, PLoS ONE, 2011, 6(9), p 1–11

Acknowledgments

The author would like to thank Jeff Sowards and Elisabeth Mansfield for establishing support for this work at NIST, and for helpful planning discussions. In addition, Jeff Sowards, Teresa Kirschling, William Cordell, Emma Schwartz, and Jolene Splett provided assistance in the laboratory or with data analysis. John Spear and Chase Williamson of the Colorado School of Mines provided insights and the A. aceti environmental isolate. The author was funded by a National Research Council Research Associateship at NIST. The University of Colorado Cancer Center DNA Sequencing and Analysis Core is supported by a NIH/NCI Cancer Center Core Support Grant (P30 CA046934).

Conflict of Interest

No conflict of interest declared.

Author information

Authors and Affiliations

Corresponding author

Additional information

Contribution of NIST, an agency of the US government; not subject to copyright in the United States.

Rights and permissions

About this article

Cite this article

France, D.C. Anticorrosive Influence of Acetobacter aceti Biofilms on Carbon Steel. J. of Materi Eng and Perform 25, 3580–3589 (2016). https://doi.org/10.1007/s11665-016-2231-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2231-0