Abstract

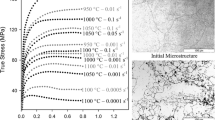

In this study, using a nonlinear estimation of strain hardening rate versus strain, a new phenomenological constitutive equation is developed. Utilizing the presented model, three new equations were presented to determine the peak strain, critical strain for initiation of dynamic recrystallization (DRX), and transition strain associated with the maximum softening rate of DRX. Also, two temperature and strain rate-sensitive parameters were introduced to generate flow stress curve at any desired deformation conditions. The predicted results were found to be in a good agreement with the ones measured experimentally. Maximum errors in prediction of peak strain, critical strain, and transition strain were about 8, 11, and 4%, respectively. In addition, evaluation of maximum errors in prediction of flow stress indicates that the presented constitutive equation gives a more precise estimation of flow stress curves in comparison with the previous models pertaining modeling of single-peak flow stress curves.

Similar content being viewed by others

References

H. Mirzadeh, Constitutive Modeling and Prediction of Hot Deformation Flow Stress Under Dynamic Recrystallization Conditions, Mech. Mater., 2015, 85, p 66–79

E. Shafiei and R. Ebrahimi, A New Constitutive Equation to Predict Single Peak Flow Stress Curves, J. Eng. Mater. Tech., 2013, 135, p 011006-4

G.R. Johnson and W.H. Cook, Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21, p 31–48

A.S. Khan and S. Huang, Experimental and Theoretical Study of Mechanical Behavior of 1100 Aluminum in the Strain Rate Range 105 to 104 S−1, Int. J. Plast., 1992, 8, p 397–424

E. Shafiei and R. Ebrahimi, A Modified Model to Estimate Single Peak Flow Stress Curves of Ti-IF Steel, ISIJ Int., 2012, 52, p 569–573

B. Farrokh and A.S. Khan, Grain Size, Strain Rate, and Temperature Dependence of Flow Stress in Ultra-Fine Grained and Nanocrystalline Cu and Al: Synthesis, Experiment, and Constitutive Modeling, Int. J. Plast., 2009, 22, p 715–732

S. Solhjoo, Determination of Flow Stress Under Hot Deformation Conditions, Mater. Sci. Eng. A, 2012, 552, p 566–568

S. Solhjoo, Determination of Flow Stress and the Critical Strain for the Onset of Dynamic Recrystallization Using a Hyperbolic Tangent Function, Mater. Des., 2014, 54, p 390–393

Y.C. Lin and X.-Y. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

R. Ebrahimi, E. Shafiei, Mathematical Modeling of Single Peak Dynamic Recrystallization Flow Stress Curves in Metallic Alloys, K. Sztwiertnia (Ed.), Book chapter, Recrystallization, Intech, 2013.

Online Wolfram Alpha Knowledge Engine, www.wolframalpha.com.

H.J. McQueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng. A., 2002, 322, p 43–63

E.I. Poliak and J.J. Jonas, A One-parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44, p 127–136

A. Najafizadeh, J.J. Jonas, G.R. Stewart, and E.I. Poliak, The Strain Dependence of Postdynamic Recrystallization in 304 H Stainless Steel, Met. Mater. Trans. A, 2006, 37, p 1899

P. Uranga, A.I. Fernandez, B. Lopez, and J.M. Rodriquez, Transition Between Static and Metadynamic Recrystallization Kinetics in Coarse Nb Microalloyed Austenite, Mater. Sci. Eng. A, 2003, 345, p 319

A. Sarkar and J.K. Chakravartty, Investigation of Progress in Dynamic Recrystallization in Two Austenitic Stainless Steels Exhibiting Flow Softening, Int. J. Met. Eng., 2013, 2, p 130–136

A. Ataati and K. Dehghani, A Study on Hot Deformation Behavior of Ni-42.5Ti-7.5Cu Alloy, Mater. Chem. Phys., 2013, 140, p 208–215

Z. Akbari, H. Mirzadeh, and J.M. Cabrera, A Simple Constitutive Model for Predicting Flow Stress of Medium Carbon Microalloyed Steel During Hot Deformation, Mater. Des., 2015, 77, p 126–131

H. Mirzadeh and A. Najafizadeh, The Rate of Dynamic Recrystallization in 17-4 PH Stainless Steel, Mater. Des., 2010, 31, p 4577–4583

R. Ebrahimi, S.H. Zahiri, and A. Najafizadeh, Mathematical Modelling of the Stress-Strain Curves of Ti-IF Steel at High Temperature, J. Mater. Process. Technol., 2006, 171, p 301–305

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shafiei, E., Dehghani, K. Prediction of Single-Peak Flow Stress Curves at High Temperatures Using a New Logarithmic-Power Function. J. of Materi Eng and Perform 25, 4024–4035 (2016). https://doi.org/10.1007/s11665-016-2228-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2228-8