Abstract

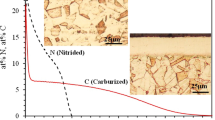

The dry sliding wear behavior of two sintered and carburized steels with different Ni amounts has been investigated. The microstructure of the two steels comprises martensite, bainite, and the Ni-rich austenite. Under the sliding conditions investigated, wear is either oxidative or adhesive. In both cases, the lower amount of the soft Ni-rich austenite results in a better wear resistance. A design procedure for parts subject to dry sliding wear applications is proposed, based on the maximum acceptable wear depth, in order to evaluate the practical significance of the differences between the two materials.

Similar content being viewed by others

References

A.I. Taskinen and M.H. Tikkanen, Wear Resistance of Sintered Steels, Mod. Dev. Powder Metall., 1984, 17, p 545–567

E.R. Leheup, D. Zhang, and J.R. Moon, The Effect of Density on Fretting Wear of Sintered Iron, Wear, 1994, 176, p 111–119

B. Dubrujeaud, M. Vardavoulias, and M. Jeandin, The Role of Porosity in the Dry Sliding Wear of a Sintered Ferrous Alloy, Wear, 1995, 174, p 155–161

G. Straffelini and A. Molinari, Dry Sliding Wear of Ferrous PM Materials, Powder Metall., 2001, 44(3), p 248–252

G. Straffelini and A. Molinari, Effect of Hardness on Rolling-Sliding Damage Mechanisms in PM Steels, Powder Metall., 2001, 44(4), p 344–350

A. Molinari, G. Straffelini, and P. Campestrini, Influence of Microstructure on Impact and Wear Behaviour of Sintered Cr and Mo Steel, Powder Metall., 1999, 42(3), p 235–241

G. Straffelini, T. Marcu Puscas, and A. Molinari, Identification of Rolling-Sliding Damage Mechanisms in Porous Alloys, Metall. Mater. Tran. A, 2000, 31(2), p 3091–3099

H. Khorsand, S.M. Habibi, H. Yoozbashizadea, K. Janghorban, S.M.S. Reihani, H. Rahmani Seraji, and M. Ashtari, The Role of Heat Treatment on Wear Behavior of Powder Metallurgy Low Alloy Steels, Mater. Des., 2002, 23(7), p 667–670

P. Vieira Muterlle, G. Straffelini, A. Molinari, and W. Pahl, Microstructural Effects in Wear of Hardened Sintered Steels Produced by Diffusion Bonded and Prealloyed Powders, Powder Metall., 2010, 53(3), p 201–207

I. Cristofolini, A. Molinari, and G. Straffelini, A Systematic Approach to Design Against Wear for Powder Metallurgy (PM) Steel Parts: The Case of Dry Rolling-Sliding Wear, Mater. Des., 2011, 32, p 2191–2198

I. Cristofolini, M. Pilla, and A. Molinari, Optimization of PM Parts for Wear Resistance Design Criteria for Dry Rolling-Sliding Wear, Adv. Powd. Metall. Part. Mater., 2011, 9, p 47–56

I. Metinoz, I. Cristofolini, and A. Molinari, Dry Sliding Wear of Powder Metallurgy Steels and Design Criteria, Int. J. Powder Metall. (in press)

K.L. Johnson, Ed., Contact Mechanics, Cambridge University Press, Cambridge, 1985

R. Haynes and J.T. Egediege, Effect of Porosity and Sinterìng Conditions on Elastic Constants of Sintered Irons, Powder Metall., 1989, 32(1), p 47–52

F.H. Stott, The Role of Oxidation in the Wear of Materials, Tribol. Int., 1998, 31, p 61–71

D.A. Rigney, L.H. Chen, M.G.S. Nayr, and A.R. Rosenfeld, Wear Processes in Sliding Systems, Wear, 1984, 100, p 195–219

ISO 286-1:2010, Geometrical Product Specifications (GPS)—ISO Code System for Tolerances on Linear Sizes—Part 1: Basis of Tolerances, Deviations and Fits.

ISO 286-2:2010, Geometrical Product Specifications (GPS)—ISO Code System for Tolerances on Linear Sizes—Part 2: Tables of Standard Tolerance Classes and Limit Deviations for Holes And Shafts.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988

Acknowledgments

Authors are grateful to Dr. Wolfgang Pahl and Dr. Alessandro De Nicolo from GKN SinterMetals (Brunico, Italy) for the production of the specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Metinoz, I., Cristofolini, I. & Molinari, A. Influence of Ni Content on Dry Sliding Wear Behavior of Sintered and Carburized Steels. J. of Materi Eng and Perform 23, 3630–3639 (2014). https://doi.org/10.1007/s11665-014-1135-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1135-0