Abstract

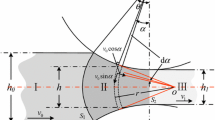

In this paper, an inverse analysis technique is used to obtain the flow curve of materials in a hot rolling finishing mill. This technique is based on minimization of the differences between the experimental and computed values. The flow curves and the friction coefficients at roll/work-piece interface are derived from two different models. Model I is based on simple slab method of analysis. Model II is based on a modified slab method in which the effect of shear stress in calculating the rolling force and torque is taken into account. It is shown that the developed inverse analysis technique is reliable and can simultaneously determine a more accurate flow stress for the material as well as a better estimation for the interface friction factors.

Similar content being viewed by others

References

J.J. Park, Prediction of the Flow Stress and Grain Size of Steel during Thick-Plate Rolling, J. Mater. Process. Technol., 2001, 113, p 581–586

G. Gutscher, H.C. Wu, G. Ngaile, and T. Altan, Determination of Flow Stress for Sheet Metal Forming Using the Viscous Pressure Bulge (VPB) Test, J. Mater. Process. Technol., 2004, 146, p 61–71

A.K. Maheshwari, A Computational Method to Crosscheck & Consistently Unifying the Deformation Test Experimental Results, Int. J. Comput. Sci. Eng. Technol., 2012, 01, p 18–25

C.M. Sellars, Modelling Microstructural Development during Hot Rolling, Mater. Sci. Technol., 1990, 6, p 1072–1081

C.M. Sellars, Recrystallization of Metals during Hot Deformation, Proceedings of the International Conference on Hot Working and Forming Processes, The Metals Society, London, 1980, p 3–15

S.B. Davenport, N.J. Silk, C.N. Sparks, and C.M. Sellars, Development of Constitutive Equations for Modeling of Hot Rolling, Mater. Sci. Technol., 2000, 16(5), p 539–546

S.R. Wang and A.A. Tseng, Macro- and Micro-modeling of Hot Rolling of Steel Coupled by a Micro-constitutive Relationship, J. Mater. Des., 1995, 16, p 315–336

C.H. Lee and T. Altan, Influence of Flow Stress and Friction upon Metal Flow in Upset Forging of Ring and Cylinders, ASME J. Eng. Ind., 1972, 94, p 775–782

M. Pietrzyk and J.G. Lenard, A Study of the Plane Strain Compression Test, Ann. CIRP, 1993, 42(1), p 331–334

J.B. Hawkyard and W Johnson, An Analysis of the Changes in Geometry of a Short Hollow Cylinder During Axial Compression, Int. J. Mech. Sci., 1967, p 799

A.T. Male and M.G. Cockcroft, Coefficient of Friction under Condition of Bulk Plastic Deformation, J. Inst. Met., 1964, 93, p 38

A. Laasraoui and J.J. Jonas, Prediction of Steel Flow Stresses at High Temperatures and Strain Rates, Metall. Trans. A, 1991, 22, p 1545–1558

S. Torizuka, T. Inoue, and K. Nagai, Uniform Formation of Fine Grained Ferrite Structure through Multi-directional Deformation, Tetsu-to-Hagane, 2000, 86(12), p 801–806

H.J. McQueen and J.J. Jonas, “Metal Forming: Interrelation between Theory and Practice” AIME Symposium, Plenum Press, New York, 1971, p 393–428

K. Osakada, T. Kawasaki, and K. Mori, A Method of Determining Flow Stress under Forming Conditions, Ann. CIRP, 1981, 30, p 135–138

E. Parteder and R. Bunten, Determination of Flow Curves by Means of a Compression Test under Sticking Friction Conditions Using an Iterative Finite-Element Procedure, J. Mater. Process. Technol., 1998, 74(1–3), p 227–233

R. Matsumoto, M. Yamasaki, M. Otsu, and Y. Kawamura, Forgeability and Flow Stress of Mg-Zn-Y Alloys with Long Period Stacking Ordered Structure at Elevated Temperatures, Jpn. Inst. Met. Mater. Trans., 2009, 50(4), p 841–846

H. Cho and T. Altan, Determination of Flow Stress and Interface Friction at Elevated Temperatures by Inverse Analysis Technique, J. Mater. Process. Technol., 2005, 170, p 64–70

A. Yanagida, J. Liu, and J. Yanagimoto, Flow Curve Determination for Metal under Dynamic Recrystallization Using Inverse Analysis, Jpn. Soc. Technol. Plast. Mater. Trans., 2003, 44(11), p 2303–2310

H. Ford and J.M. Alexander, Simplified Hot Rolling Calculations, J. Inst. Met., 1963–1964, 92, p 397–404.

R. Hill, Mathematical Theory of Plasticity, Oxford University Press, London, 1950, p 245

D.R. Bland and H. Ford, The Calculation of Roll Force and Torque in Cold Strip Rolling, Proc. Inst. Mech. Eng., 1948, 159, p 144

L.A. Lalli, An Analytical Rolling Model Including through Thickness Shear Stress Distribution, J. Eng. Mater. Technol. ASME, 1984, 106, p 1–8

V.I. Kaplanov, Contact Friction in the Hot Rolling of Steel, Steel Transl., 2008, 38(4), p 322–326

X. Tan, Comparison of Friction Models in Bulk Metal Forming, Tribol. Int., 2002, 35, p 385–393

F. Siciliano and E.I. Polak, Modelling of the Resistance to Hot Deformation and the Effect of Microalloying in High-Al Steels under Industrial Conditions, Mater. Sci. Forum, 2005, 500–501, p 195–202

S. Byon, D. Na, and Y. Lee, Flow Stress Equation in Range of Intermediate Strain Rates and High Temperatures to Predict Roll Force in Four-Pass Continuous Rod Rolling, Trans. Nonferr. Met. Soc. China, 2013, 23, p 742–748

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aghasafari, P., Salimi, M. & Daraei, A. Flow Stress Evaluation in Hot Rolling of Steel. J. of Materi Eng and Perform 23, 2819–2828 (2014). https://doi.org/10.1007/s11665-014-1049-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1049-x