Abstract

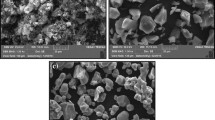

In the present work, wear resistance of a homogeneous and functionally graded Al/SiC nanocomposite produced by friction stir processing was studied. According to the wear test results, the friction coefficient of the functionally graded nanocomposite was slightly less than that of the homogeneous nanocomposite (i.e., 0.7 compared to 0.8); this may be due to higher surface hardness of the functionally graded composite. In both cases, the weight loss increased with increasing applied loads; however, weight loss for the functionally graded nanocomposite was lesser under each applied load. Regarding surface studies by Scanning Electron Microscope (SEM) and Optical Microscope (OM), the functionally graded nanocomposite showed less micro-galling and other surface damages; this can be attributed to its surface hardness and high work of fracture.

Similar content being viewed by others

References

S. Nai, M. G, and C. Lim, Synthesis and Wear Al Based Functionally Graded Composite, Mater. Sci. Technol., 2004, 20, p 57–67

Y. Sahin, Wear Behaviour of Aluminium Alloy and Its Composites Reinforced by SiC Particles Using Statistical Analysis, Mater. Des., 2003, 24, p 95–103

B. Dikici, M. G, and C. Tekmen, Corrosion Behavior of an Artificially Aged (T6) Al-Si-Mg-Based Metal Matrix Composite, J. Compos. Mater., 2006, 40, p 1259–1269

D.B. Miracle and S.L. Donaldson, ASM Handbook: Composites, Vol 21, ASM International, Material Park, 2001

N. Chawla and K.K. Chawla, Metal Matrix Composites, Springer, New York, 2006

B. Cantor, F. D, and I. Stone, Metal and Ceramic Matrix Composites: An Oxford-Kobe Materials Text, Institute of Physics Publishing, Bristol and Philadelphia, UK, 2004

R.S. Mishra, Low Temperature Superplasticity in a Friction-Stir-Processed Ultrafine Grained Al-Zn-Mg-Sc Alloy, Acta Mater., 2005, 53(15), p 4211–4223

C.J. Lee, H.J. C, and P.J. Hsieh, Mg Based Nano-Composites Fabricated by Friction Stir Processing, Scripta Mater., 2006, 54(7), p 1415–1420

D.K. Lim, S. T, and A.P. Gerlich, Synthesis of Multi-Walled CNT Reinforced Aluminium Alloy Composite Via Friction Stir Processing, Mater. Sci. Eng., A, 2009, 507, p 194–199

Y. Moruisad, F. H, T. Nagaoka, K. Nogi, and M. Fukusumi, Fullerene/A5083 Composites Fabricated by Material Flow During Friction Stir Processing, Composites A, 2007, 38, p 2097–2101

A. Shafiei-Zargani, K.-B.S. F, and A. Zareihanzaki, Microstructures and Mechanical Properties of Al/Al2O3 Surface Nano-Composite Layer Produced by Friction Stir Processing, Mater. Sci. Eng., A, 2009, 500, p 84–91

R.S. Mishra, M.M. W, S.X. Mcfadden, N.A. Mara, and A.K. Mukherjee, High Strain Rate Superplasticity in a Friction Stir Processed 7075 Al Alloy, Scripta Mater., 2000, 42(2), p 163–168

J.R. Gomes, A.R. R, A.C. Vieira, A.S. Miranda, and L.A. Rocha, Friction and Wear Properties of Functionally Graded Aluminium Matrix Composites, Mater. Sci. Forum, 2003, 425, p 91–96

C.S. Ramesh, A.R.A. K, N. Ravikumar, and P. Savanprabhu, Prediction of Wear Coefficient of Al6061-TiO2 Composites, Wear, 2005, 259, p 602–608

J. Hua, D.Y. L, and R. Llewellyn, Computational Investigation of Microstructural Effects on Abrasive Wear of Composite Materials, Wear, 2005, 259, p 6–17

J.K.M. Kwok and S.C. L, High-Speed Tribological Properties of Some Al/SiCp Composites: I. Frictional and Wear-Rate Characteristics, Compos. Sci. Technol., 1999, 59, p 55–63

M. Salehi, M. S, and J. Aghazadeh Mohandesi, Optimization of Process Parameters for Producing AA6061/SiC Nanocomposites by Friction Stir Processing, Trans. Nonferrous Met. Soc. China, 2012, 22, p 1055–1063

E. Hornbogen, The Role of Work of Fracture in the Wear of Metals, Wear, 1975, 33, p 251–259

I. Sevim, Effect of Work of Fracture on Abrasive Wear Resistance of Steels, Mater. Des., 2006, 27, p 911–919

R.L. Deuis, C. S, and J.M. Yellup, Abrasive Wear of Aluminium Composites—A Review, Wear, 1996, 201, p 132–144

S. Amada and S. Untao, Fracture Properties of Bamboo, Composites B, 2001, 32, p 451–459

L.L.M. Mishnaevsky, Jr., Functionally Gradient Metal Matrix Composites: Numerical Analysis Of The Microstructure-Strength Relationships, Compos. Sci. Technol., 2006, 66, p 1873–1887

C. Lin, Structure and Properties of Functionally Gradient Aluminium Alloy 2124/SiC Composites, Mater. Sci. Technol., 1994, 10, p 659–664

E. Rabinowicz, Friction and Wear of Materials, Wiley, New York, 1995

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saadatmand, M., Mohandesi, J.A. Comparison Between Wear Resistance of Functionally Graded And Homogenous Al-SiC Nanocomposite Produced by Friction Stir Processing (FSP). J. of Materi Eng and Perform 23, 736–742 (2014). https://doi.org/10.1007/s11665-013-0839-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0839-x