Abstract

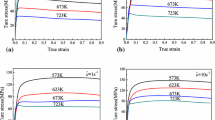

A model is developed to predict the constitutive flow behavior of cadmium during compression test using artificial neural network (ANN). The inputs of the neural network are strain, strain rate, and temperature, whereas flow stress is the output. Experimental data obtained from compression tests in the temperature range −30 to 70 °C, strain range 0.1 to 0.6, and strain rate range 10−3 to 1 s−1 are employed to develop the model. A three-layer feed-forward ANN is trained with Levenberg-Marquardt training algorithm. It has been shown that the developed ANN model can efficiently and accurately predict the deformation behavior of cadmium. This trained network could predict the flow stress better than a constitutive equation of the type \( \dot{\upvarepsilon } = A\sinh (\upalpha /\upsigma )^{n} \exp ( - Q/RT) \).

Similar content being viewed by others

References

W. Hosford, Mechanical Behavior of Materials, Cambridge University Press, Cambridge, 2005

S. Mandal, P.V. Sivaprasad, S. Venugopal, and K.P.N. Murthy, Constitutive Flow Behaviour of Austenitic Stainless Steels Under Hot Deformation: Artificial Neural Network Modelling to Understand, Evaluate and Predict, Model. Simul. Mater. Sci. Eng., 2006, 14, p 1053–1070

H.-Y. Li, D.-D. Wei, Y.-H. Li, and X.-F. Wang, Application of Artificial Neural Network and Constitutive Equations to Describe the Hot Compressive Behavior of 28CrMnMoV Steel, Mater. Des., 2012, 35, p 557–562

H. Sheikh and S. Serajzadeh, Estimation of Flow Stress Behavior of AA5083 Using Artificial Neural Networks with Regard to Dynamic Strain Ageing Effect, J. Mater. Process. Technol., 2008, 196, p 115–119

R. Kapoor, D. Pal, and J.K. Chakravartty, Use of Artificial Neural Networks to Predict the Deformation Behavior of Zr-2.5Nb-0.5Cu, J. Mater. Process. Technol., 2005, 169, p 199–205

D.H. Sastry, Y.V.R.K. Prasad, and K.I. Vasu, On the Stacking Fault Energies of some Close-Packed Hexagonal Metals, Scripta Metal., 1969, 3, p 927–929

T. Sakai and J.J. Jonas, Dynamic Recrystallization: Mechanical and Microstructural Considerations, Acta Metall., 1984, 32, p 189–209

A. Sarkar, J.K. Chakravartty, and I. Samajdar, The Avrami Kinetics of Dynamic Recrystallization in Cadmium, Metall. Mater. Trans. A, 2010, 41, p 2466–2470

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14, p 1136–1138

C. Zener and H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15, p 22–32

H.K.D.H. Bhadeshia, Neural Networks in Materials Science, ISIJ Int., 1999, 39(1999), p 966–979

Y.M. Zhang, S. Yang, and J.R.G. Evans, Revisiting Hume-Rothery’s Rules with Artificial Neural Networks, Acta Mater., 2008, 56, p 1094–1105

Z. Guo, S. Malinov, and W. Sha, Modelling Beta Transus Temperature of Titanium Alloys Using Artificial Neural Network, Comput. Mater. Sci., 2005, 32, p 1–12

K. Hornik, Some New Results on Neural Network Approximation, Neural Netw., 1993, 6, p 1069–1072

W. Sha, Comment on “Flow Forecasting for a Hawaii Stream Using Rating Curves and Neural Networks”, J. Hydrol., 2007, 340, p 119–121

S. Srinivasulu and A. Jain, A Comparative Analysis of Training Methods for Artificial Neural Network Rainfall-Runoff Models, Appl. Soft. Comput., 2006, 6, p 295–306

J.D. Olden and D.A. Jackson, Illuminating the “black box”: A Randomization Approach for Understanding Variable Contributions in Artificial Neural Networks, Ecol. Model., 2002, 154, p 135–150

M. Gevrey, I. Dimopoulos, and S. Lek, Review and Comparison of Methods to Study the Contribution of Variables in Artificial Neural Network Models, Ecol. Model., 2003, 160, p 249–264

G.D. Garson, Interpreting Neural-Network Connection Weights, Artif. Intell. Expert, 1991, 6, p 47–51

A.T.C. Goh, Back-Propagation Neural Networks for Modeling Complex Systems, Artif. Intell. Eng., 1995, 9, p 143–151

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarkar, A., Chakravartty, J.K. Prediction of Flow Stress in Cadmium Using Constitutive Equation and Artificial Neural Network Approach. J. of Materi Eng and Perform 22, 2982–2989 (2013). https://doi.org/10.1007/s11665-013-0597-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0597-9