Abstract

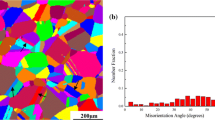

By means of full heat treatment, microstructure observation, lattice parameters determination, and the measurement of creep curves, an investigation has been conducted into the microstructure and creep mechanisms of FGH95 Ni-based superalloy. Results show that after the alloy is hot isostatically pressed, coarse γ′ phase discontinuously distributes along the previous particle boundaries. After solution treatment at high temperature and aging, the grain size has no obvious change, and the amount of coarse γ′ phase decreases, and a high volume fraction of fine γ′ phase dispersedly precipitates in the γ matrix. Moreover, the granular carbides are found to be precipitated along grain boundaries, which can hinder the grain boundaries’ sliding and enhance the creep resistance of the alloy. By x-ray diffraction analysis, it is indicated that the lattice misfit between the γ and γ′ phases decreases in the alloy after full heat treatment. In the ranges of experimental temperatures and applied stresses, the creep activation energy of the alloy is measured to be 630.4 kJ/mol. During creep, the deformation mechanisms of the alloy are that dislocations slip in the γ matrix or shear into the γ′ phase. Thereinto, the creep dislocations move over the γ′ phase by the Orowan mechanism, and the \( \left\langle { 1 10 } \right\rangle \) super-dislocation shearing into the γ′ phase can be decomposed to form the configuration of (1/3) \( \left\langle { 1 12 } \right\rangle \) super-Shockleys’ partials and the stacking fault.

Similar content being viewed by others

References

Z.Z. Lu, C.L. Liu, and Z.F. Yue, Probabilistic Safe Analysis of the Working Life of a Powder Metallurgical Turbine Disc, Mater. Sci. Eng. A, 2005, 395, p 153–159

L.M. Bianchi, Argon Atomized Superalloys for Jet Engine Discs, European Powder Metallurgy Conference on Meeting the Challenges of a Changing Market Place, 2003, vol 3, p 328–332

J. Zou and W. Wang, Development and Application of P/M Superalloy, J. Aeronaut. Mater., 2006, 26(3), p 244–249

H. Li, X. Song, Y. Wang et al., Stability of γ Phase in FGH95 Superalloy, Rear Metal Materials and Engineering, 2009, 38(1), p 64–67

S. Tian, Y. Liu, X. Zhou et al., Creep Behaviors of FGH95 Powder Ni-Base Superalloy, Chin. J. Aeronaut., 2009, 22(4), p 444–448

X. Liu, X. Chen, X. Hou et al., Damage and Fracture Specialty of FGH95 Powder Superalloy, Rear Metal Mater. Eng., 2009, 38(7), p 1179–1183

X. Xie, L. Zhang, M. Zhang, et al., Micro-mechanical Behavior Study of Non-metallic Inclusions in P/M Disk Superalloy Rene’95[C], Superalloys, TMS, 2004, p 451–458

S. Tian, J. Xie, X. Zhou et al., Microstructure and Creep Behavior of FGH95 Nickel-Base Superalloy, Mater. Sci. Eng. A, 2011, 528, p 2076–2084

G. Tian, G. Jia, G. Liu et al., Cooling Precipitation and Strengthening for Different Locations of a Powder Metallurgy Nickel-Base Superalloy Disk, Trans. Mater. Heat Treat., 2008, 29(3), p 126–130

S. Tian, J. Xie, X. Zhou et al., Effects of Quenching Technics on Microstructure and Creep Properties of FGH95 Superalloy, Chin. J. Nonferrous Metals, 2010, 20(5), p 852–858

J. Jian, T. Yu, Z. Yi-wen et al., Effect of Ageing Heat Treatment on Microstructure and Mechanical Properties of PM Superalloy FGH95, Powder Metall. Ind., 2010, 20(1), p 25–30

S. Tian, J. Xie, X. Zhou et al., Influence of Solution Temperature on Microstructure and Creep Properties of FGH95 Nickel-Base Superalloy, Trans. Mater. Heat Treat., 2010, 31(11), p 122–127

R.R. Unocic, G.B. Viswanathan, P.M. Sarosi et al., Mechanisms of Creep Deformation in Polycrystalline Ni-Base Disk Superalloys, Mater. Sci. Eng. A, 2008, 483–484, p 25–32

L. Kovarik, R.R. Unocic, J. Li, and M.J. Mills, The Intermediate Temperature Deformation of Ni-based Superalloys: Importance of Reordering, J. Miner., 2009, 61(2), p 42–48

G.B. Viswanathan, P.M. Sarosi, M.F. Henry et al., Investigation of Creep Deformation Mechanisms at Intermediate Temperatures in René 88 DT, Acta Mater., 2005, 53, p 3041–3057

S. Tian, J. Xie, X. Zhou et al., Creep Behavior and Influencing Factors of FGH95 Nickel Base Superalloy, Rare Metal Mater. Eng., 2011, 40(5), p 807–812

J. Li, S. Tian, J. Xie, et al., Composing Phases and granularity distribution of γ′ Phase in FGH95 Nickel Base Superalloy, J. Mater. Eng., 2010, (supplement 1), p 206–209

S. Tian, X. Yu, J. Yang et al., Deformation Features of a Nickel-Base Superalloy Single Crystal During Compress Creep, Mater. Sci. Eng. A, 2004, 379, p 141–147

Y. Zhang, Y. Zhang, F. Zhang et al., The Effect of Solution Temperature on Properties of FGH95 PM Superalloy Manufactured by PREP, Trans. Mater. Heat Treat., 2002, 23(3), p 72–75

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, J., Tian, Sg. & Zhou, Xm. Creep Properties and Deformation Mechanisms of a FGH95 Ni-based Superalloy. J. of Materi Eng and Perform 22, 2048–2055 (2013). https://doi.org/10.1007/s11665-013-0477-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0477-3