Abstract

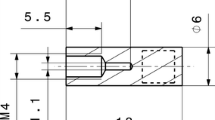

Kinetics of the reaction that occur during the austempering heat treatment in unalloyed and alloyed ductile irons with 1Cu-0.25Mo, 1Ni-0.25Mo, and 0.7Cu-1Ni-0.25Mo, was studied. The austenitization and austempering cycles were achieved by isothermal dilatometry in cylindrical samples of 2 mm in diameter and 12 mm in length. The specimens were austenitized at 870 °C for 120 min, followed by isothermal holding for 300 min at temperatures between 270 and 420 °C. Kinetic parameters such as the order of reaction “n” and the rate of reaction “k” were calculated using the Johnson-Mehl equation while the empirical activation energy was calculated by means of the Arrhenius equation. It was found that the values of “k” decreased with the addition of Cu, Ni, and Mo as well as with the reduction of the isothermal temperature. The activation energy changes with the austempering temperature, in the range 30,348-58,250 J/mol when the heat treatment was carried out between 370 and 420 °C and 10,336-26,683 J/mol when the temperature varied from 270 to 350 °C. The microstructures in samples austempered at 370 and 315 °C were observed by transmission electron microscopy. No carbides precipitation was observed on samples heat treated at 370 °C for less than 120 min, while at 315 °C carbides of hexagonal structure ε(Fe2.4C) were found from the beginning of the transformation. The smallest value of activation energy and a slower kinetic transformation seem to be related with the presence of a carbide phase. Additionally, the time results obtained for transformation fractions of 0.05 and 0.95 by the dilatometry analysis were used to build the temperature-time-transformation diagrams for the irons.

Similar content being viewed by others

References

K.L. Hayrynen and J.R. Keough, The Status of Austempered Cast Irons in 2007, AFS Trans., 2008, 116, p 747–757

American Foundry Society, 43rd Census of World Casting Production 2008, Mod. Cast., 2009, 98(12), p 17–21

M.F. Hafiz, Tensile and Impact Properties of Conventional and Austempered SG-Cast Irons, AFS Trans., 2009, 117, p 445–452

K. Hanzlikova, S. Véchet, and J. Kohout, Influence of Microstructure Composition on Mechanical Properties of Austempered Ductile Iron, Kovove Mater., 2008, 46, p 117–121

D.M. Stefanescu, R. Ruxanda, and L.P. Dix, The Metallurgy and Tensile Mechanical Properties of Thin Wall Spheroidal Graphite Irons, Int. J. Cast Metals Res., 2003, 16(1–3), p 319–324

A.P. Druschitz and D.C. Fitsgerald, Lightweight Iron and Steel Casting for Automotive Applications, 2000 SAE World Congress, Detroit, Michigan, USA, 2000, p 1–8

M.M. Mourad, K.M. Ibrahim, and A.A. Nofal, Optimizing the Properties of Thin Wall Austempered Ductile Iron, 68th World Foundry Congress, Chennai, India, 2008, p 161–166

“Terminology Relating to Iron Casting”, A 644, Annual book of ASTM Standards, Part 1, ASTM, p 333–334

C. Valdés, M.J. Pérez, M. Figueroa, and L.E. Ramirez, Austempered Ductile Iron with Dual Matrix Structures, Rev. Mex. Fís., 2009, 55, p 48–51

J. Zimba, D.J. Simbi, and E. Navara, Austempered Ductile Iron: An Alternative Material for Earth Moving Components, Cem. Concr. Compos., 2003, 25, p 643–649

M. Nili-Ahmadabadi and S. Farjami, Application of Computational Thermodynamics and Kinetic to Control of High Mn Ductile Iron Austempering, Int. J. Cast Metals Res., 2003, 16(1–3), p 71–75

“Specification for Austempered Ductile Iron Castings”, A 897, Annual book of ASTM Standards, Part 1, ASTM, p 557–562

J.W. Chistian, The Theory of Transformation in Metals and Alloys, 3rd ed., Pergamon Press, Oxford, 2002, p 538–546

L. Sidjanin, R.E. Smallman, and J.M. Young, Electron Microstructure and Mechanical Properties of Silicon and Aluminum Ductile Irons, Acta Metall. Mater., 1994, 42, p 3149–3156

L. Sidjanin and R.E. Smallman, Metallography of Bainitic Transformation in Austempered Ductile Iron, Mater. Sci. Technol., 1992, 8, p 1095–1103

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pérez, M.J., Cisneros, M.M., Almanza, E. et al. Kinetic Study of the Austempering Reactions in Ductile Irons. J. of Materi Eng and Perform 21, 2460–2466 (2012). https://doi.org/10.1007/s11665-012-0194-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0194-3