Abstract

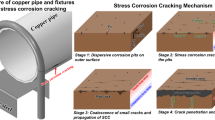

A jacketed underground pipeline made of 304 stainless steel tubing to transport utility water in a petrochemical plant at ambient temperature was perforated after few months of operation. Perforation started preferentially at the outer bottom surface of the pipe in the weld heat-affected zones where the insulating coating was damaged. Detailed microstructural characterization was carried out to determine the cause of failure using optical metallography, x-ray diffraction, scanning electron microscopy combined with energy dispersive spectroscopy, and transmission electron microscopy. Experimental results indicated that the failure occurred by interaction between the outer bottom surface of the pipe and surrounding environment leading to pitting and stress corrosion cracking in the presence of chloride ions. This could have been aided by residual welding stresses and the characteristic low stacking fault energy of the material.

Similar content being viewed by others

References

K.H. Lo, C.H. Shek, and J.K. Lai, Recent Developments in Stainless Steel, Mater. Sci. Eng. R, 2009, 65, p 39

Y. Gong, J. Cao, X.H. Meng, and Z.G. Yang, Pitting Corrosion on 316L Pipes, Mater. Corros., 2009, 60(11), p 899

G. Schiroky, D. Anibal, A. Okeremi, and C. Speed, Preventing Pitting and Crevice Corrosion of Offshore Stainless Steel Tubing, World Oil, April Issue (2009) p 73

M. Riahi and R. Alipour, Predictive Model for Determination of Pitting Corrosion in Stainless Steel Pipes, Mater. Eval., 2004, 62(3), p 373

E. Hur, G. Bereket, and Y. Sahin, Corrosion Inhibition of Stainless Steels by Polyaniline poly (2-Chloroaniline), and Poly (aniline-co-2-chloroaniline), Prog. Org. Coat., 2006, 57, p 149

F. Elshawesh, A. Elhoud, and O. Elraghai, Corrosion and Cracking Under Insulation of Type 304 Stainless Steel at Ambient Temperature, Corros. Eng. Sci. Technol., 2003, 38(3), p 239

P.A. Schweitzer, Stainless Steels, Corrosion and Corrosion Protection Handbook, P.A. Schweitzer, Ed., Marcel Dekker, New York, 1983, p 37–53

H.L. Logan, The Stress Corrosion of Metals, John Wiley and Sons, New York, 1966, p 129–136

K. Kishimoto, M. Kikuchi, T. Shoji, and M. Saks, Localized Deformation Induced Intergranular Stress Corrosion Cracking of Austenitic Alloys in Water, Adv. Fract. Fail. Prev., 2004, 261, p 885

ASM Metals Handbook, Atlas of Microstructures of Industrial Alloys, Vol 7, 8th ed., ASM International, USA, 1973, p 134

Acknowledgments

It is a pleasure to acknowledge the continued support of King Fahd University of Petroleum & Minerals and the Saudi Ministry of Higher Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tawancy, H.M., Al-Hadhrami, L.M. Case Study: Pitting and Stress Corrosion Cracking in Heat-Affected Zone of Welded Underground 304 Stainless Steel Pipe. J. of Materi Eng and Perform 21, 1757–1762 (2012). https://doi.org/10.1007/s11665-011-0076-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-0076-0