Abstract

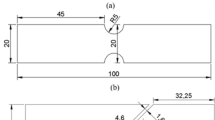

Characterizing the behavior of superplastic materials is largely based on the uniaxial tensile test; yet the unique nature of these materials requires a particularly tailored testing methodology, different to that used with conventional materials. One of the crucial testing facets is the specimen geometry, which has a great impact on the outcome of a superplastic tensile test, as a result of the associated extreme conditions. And while researchers agree that it should take a notably different form than the typical dog-bone shape; there is no universal agreement on the specimen’s particular size and dimensions, as evident by the disparities in test specimens used in the various superplastic testing efforts found throughout the literature. In view of that, this article is dedicated to understanding the effects of specimen geometry on the superplastic behavior of the material during tensile testing. Deformation of the Ti6Al4V titanium alloy is FE simulated based on a multitude of specimen geometries, covering a wide range of gauge length, gauge width, grip length, and grip width values. The study provides key insights on the influences of each geometrical parameter as well as their interactions, and provides recommendations on selecting the specimen’s proportions for accurate and unified tensile testing of superplastic materials.

Similar content being viewed by others

References

“Method for Evaluation of Tensile Properties of Metallic Superplastic Materials,” JIS H 7501, 2002

“Standard Test Method for Determining the Superplastic Properties of Metallic Sheet Materials,” ASTM E2448, 2005

“Method for Evaluation of Tensile Properties of Metallic Superplastic Materials,” BS ISO 20032, 2007

H. Watanabe, A. Takara, H. Somekawa, T. Mukai, and K. Higashi, Effect of Texture on Tensile Properties at Elevated Temperatures in an AZ31 Magnesium Alloy, Scripta Mater., 2005, 52, p 449–454

P. Mukhopadhyay, S. Biswas, and A. Chokchi, Deformation Characterization of Superplastic AA7475 Alloy, Trans. Indian Inst. Met., 2009, 62(2), p 149–152

J. Liu, D. Chen, Z. Chen, and H. Yan, Deformation Behavior of AZ31 Magnesium Alloy During Tension at Moderate Temperatures, J. Mater. Eng. Perform., 2009, 18(7), p 966–972

F. Abu-Farha and M. Khraisheh, Analysis of Superplastic Deformation of AZ31 Magnesium Alloy, J. Adv. Eng. Mater., 2007, 9(9), p 777–783

J. Chang, E. Taleff, and P. Krajewsky, Effect of Microstructure on Cavitation during Hot Deformation of a Fine-Grained Aluminum-Magnesium Alloy as Revealed through Three-Dimensional Characterization, Metall. Mater. Trans. A, 2009, 40(13), p 3128–3137

K. Johnson, M. Khaleel, C. Lavender, S. Pitman, J. Smith, M. Smith, and C. Hamilton, The Effect of Specimen Geometry on the Accuracy of Constitutive Relations in a Superplastic 5083 Aluminum Alloy, Mater. Sci. Forum, 1994, 170–172, p 627–632

F. Abu-Farha and R. Curtis, Quick-Mount Grips: Towards an Improved Standard for Uniaxial Tensile Testing of Metallic Superplastic Sheets, Mat.-wiss. u. Werkstofftech., 2009, 40(11), p 836–841

P. Bate, N. Ridley, and K. Sotoudeh, Effect of Gauge Length in Superplastic Tensile Tests, Mater. Sci. Technol., 2008, 24(10), p 1265–1270

X. Ding, H. Zbib, C. Hamilton, and A. Bayoumi, On the Optimization of Superplastic Blow-Forming Processes, J. Mater. Eng. Perform., 1995, 4(4), p 474–485

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nazzal, M., Abu-Farha, F. & Curtis, R. Finite Element Simulations for Investigating the Effects of Specimen Geometry in Superplastic Tensile Tests. J. of Materi Eng and Perform 20, 865–876 (2011). https://doi.org/10.1007/s11665-010-9727-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9727-9