Abstract

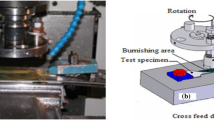

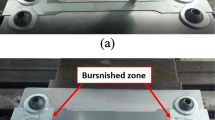

A newly developed ball burnishing tool was designed and tested for surface finishing of large flat surfaces in a shortest possible time. Optimization and analysis of the burnishing process were carried on AISI 1010 steel hot-rolled plates using the Taguchi technique and response surface methodology (RSM) to identify the effect of burnishing parameters (i.e., burnishing speed, burnishing force, and feed rate) on surface roughness, surface hardness, and microstructure of burnished surfaces. The optimal burnishing parameters were found after conducting the Taguchi’s L25 matrix experiments and obtaining the response models for the surface roughness and the hardness. It was found that the burnishing force has the most influential effect on the surface roughness and hardness, followed by the burnishing speed, and least influence by the feed rate. In addition, microstructural examinations of the burnished surface indicate that burnishing force more than 400 N causes flaking of the burnished surfaces. The optimal burnishing parameters for the steel plates were a combination of a burnishing speed of 235 rpm, a burnishing force of 400 N, and a feed rate of 0.18 mm/rev. Using these parameters, the mean surface roughness has been improved from Ra = 2.48 to 1.75 μm, while the hardness increases from 59 to 65.5 HRB.

Similar content being viewed by others

References

M.H. El-Axir, O.M. Othman, and A.M. Abodiena, Improvements in Out-of-Roundness and Microhardness of Inner Surfaces by Internal Ball Burnishing Process, J. Mater. Process. Technol., 2008, 196, p 120–128

M.H. El-Axir and M.M. El-Khabeery, Influence of Orthogonal Burnishing Parameters on Surface Characteristics for Various Materials, J. Mater. Process. Technol., 2003, 132, p 82–89

M.M. El-Khabeery and M.H. El-Axir, Experimental Techniques for Studying the Effects of Roller-Burnishing Parameters on Surface Integrity, Int. J. Mach. Tools Manuf., 2001, 41, p 1705–1719

N.H. Loh, S.C. Tam, and S. Miyazawa, A Study of the Effect of Ball-Burnishing Parameters on Surface Roughness Using Factorial Design, J. Mech. Work. Technol., 1989, 18, p 53–61

M.H. El-Axir, O.M. Othman, and A.M. Abodiena, Study of Inner Surface Finishing of Aluminum Alloy 2014 by Ball Burnishing Process, J. Mater. Process. Technol., 2008, 202, p 435–442

M.H. El-Axir, An Investigation into Roller Burnishing, Int. J. Mach. Tools Manuf., 2000, 40, p 1603–1617

H. Hamadache, L. Laouar, N.E. Zeghib, and K. Chaoui, Characteristics of Rb40 Steel Superficial Layer Under Ball and Roller Burnishing, J. Mater. Process. Technol., 2006, 180(1–3), p 130–136

M.H. El-Axir and A.A. Ibrahim, Some Surface Characteristics Due to Center Rest Ball Burnishing, J. Mater. Process. Technol., 2005, 167, p 47–53

S. Fang-Jung and H. Chih-Cheng, Surface Finishing of Hardened and Tempered Stainless Tool Steel Using Sequential Ball Grinding, Ball Burnishing and Ball Polishing Processes on a Machining Centre, J. Mater. Process. Technol., 2008, 205, p 249–258

L. Liviu, N.V. Sorin, and M. Ioan, Effects of Working Parameters on Surface Finish in Ball-Burnishing of Hardened Steels, Precis. Eng., 2005, 29, p 253–256

P. Zhang and P. Lindemann, Effect of Roller Burnishing on the High Cycle Fatigue Performance of the High-Strength Magnesium Alloy AZ80, Scr. Mater., 2005, 52, p 1011–1015

M. Fattouh and M.M. El-Khabeery, Residual Stress Distribution in Burnishing Solution Treated and Aged 7075 Aluminum Alloy, Int. J. Mach. Tools Manuf., 1989, 29(1), p 153–160

A.M. Hassan and A.S. Al-Bsharat, Influence of Burnishing Process on Surface Roughness, Hardness and Microstructure of Some Non-Ferrous Metals, Wear, 1996, 199, p 1–8

S. Toshioki, S. Hiroyuki, and T. Masaomi, Development of a New Tool to Generate Compressive Residual Stress Within a Machined Surface, Int. J. Mach. Tools Manuf., 2004, 44, p 1215–1221

A.M. Hassan and A.M.S. Momani, Further Improvements in Some Properties of Shot Peened Components Using the Burnishing Process, Int. J. Mach. Tools Manuf., 2000, 40, p 1775–1786

A.M. Hassan and A.S. Al-Bsharat, Improvements in Some Properties of Non-Ferrous Metals by the Application of the Ball-Burnishing Process, J. Mater. Process. Technol., 1996, 59, p 250–256

K. Palka, A. Weroński, and K. Zaleski, Mechanical Properties and Corrosion Resistance of Burnished X5CrNi 18-9 Stainless Steel, J. Achiev. Mater. Manuf. Eng., 2006, 16, p 57–62

L.N. López de Lacalle, A. Lamikiz, J. Muñoa, and J.A. Sánchez, Quality Improvement of Ball-End Milled Sculptured Surfaces by Ball Burnishing, Int. J. Mach. Tools Manuf., 2005, 45, p 1659–1668

S. Fang-Jung and C. Chien-Hua, Freeform Surface Finish of Plastic Injection Mold by Using Ball-Burnishing Process, J. Mater. Process. Technol., 2003, 140, p 248–254

Y.C. Lin, B.H. Yan, and F.Y. Huang, Surface Improvement Using a Combination of Electrical Discharge Machining with Ball Burnish Machining Based on the Taguchi Method, Int. J. Adv. Manuf. Technol., 2001, 18, p 673–682

T.A. El-Taweel and M.H. El-Axir, Analysis and Optimization of the Ball Burnishing Process Through the Taguchi Technique, Int. J. Adv. Manuf. Technol., 2009, 41, p 301–310

Acknowledgments

The technical assistance from the Electron Microscopy Unit at Kuwait University and the ISSAT-Kairouan are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gharbi, F., Sghaier, S., Al-Fadhalah, K.J. et al. Effect of Ball Burnishing Process on the Surface Quality and Microstructure Properties of AISI 1010 Steel Plates. J. of Materi Eng and Perform 20, 903–910 (2011). https://doi.org/10.1007/s11665-010-9701-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9701-6