Abstract

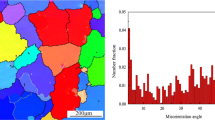

Isothermal compression tests on Al-4Cu-Mg alloy were carried out in semi-solid state. Deformation behavior and microstructural evolution are discussed in this paper. Meanwhile, a new constitutive equation, which couples the grain size and liquid volume fraction, has been established for the semi-solid deformation behavior. The results show that the maximum difference between the calculated with the experimental data is less than 15%. The present equation is satisfactory for describing the correlation between the flow stress and microstructure of semi-solid Al-4Cu-Mg alloy. The coupled simulation of the deformation behavior and microstructural evolution during the semi-solid forming would be conducted easily through writing the present equation in a FE code.

Similar content being viewed by others

References

P.A. Joly and R. Mehrabian, The Rheology of a Partially Solid Alloy, J. Mater. Sci., 1976, 11, p 1393–1418

W.M. Van Haaften, W.H. Kool, and L. Katerman, Tensile Behavior of Semisolid Industrial Aluminum Alloys AA3104 and AA5182, Mater. Sci. Eng. A, 2002, 336, p 1–6

J.S. Gunasekera, Development of a Constitutive Model for Mushy Materials, Proceedings of the 2nd International Conference on Semi-Soild Processing of Alloys and Composites, Cambridge, USA, 1992, p 211–222

C.G. Kang and H.K. Jung, Finite Element Analysis with Deformation Behavior Modeling of Globular Microstructure in Forming Process of Semi-Solid Materials, Int. J. Mech. Sci., 1999, 41, p 1423–1445

R. Kopp, J. Choi, and D. Neudenberger, Simple Compression Test and Simulation of an Sn-15%Pb Alloy in the Semi-Solid State, J. Mater. Process. Technol., 2002, 6376, p 1–7

J.H. Yoon, Y.T. Im, and N.S. Kim, Finite Element Modeling of the Deformation Behavior of Semi-Solid Materials, J. Mater. Process. Technol., 2001, 113, p 153–159

A. Rassili, C. Geuzaine, and W. Legros, Numerical Simulations and Experimental Investigations of the Semi-Solid Metal Processing of Steels, Proceedings of the 7th International Conference on Semi-Solid Processing of Alloys and Composites, Tsukuba, Japan, 2002, p 367–372

X.G. Li, S.S. Xie, and Y.X. Jiang, Rigid-Viscoplastic Finite Element Analysis on Semi-Solid Thixoforming Automobile Wheel of AZ91D Magnesium Alloy, Proceedings of the 8th International Conference on Semi-Solid Processing of Alloys and Composites, Limassol, Cyprus, 2004, p 377–383

D. Larouche, J. Langlais, W.L. Wu, and M. Bouchard, A Constitutive Model for the Tensile Deformation of a Binary Aluminum Alloy at High Fractions of Solid, Metall. Mater. Trans., 2006, 37B, p 431–443

H.P. Pan, Z.Y. Ding, Y.S. Dong, and S.S. Xie, Study of the Constitutive Model for Thixoforming of Semi-Solid AlSi7 Mg Alloy, Acta Metall. Sin., 2003, 139, p 369–374

H.V. Atkinson, Modelling the Semisolid Processing of Metallic Alloy, Prog. Mater. Sci., 2005, 50, p 341–412

H.T. Jiang, X.L. Li, A.M. Xiong, and M.Q. Li, Fabrication and Microstructure Evolution of Semi-Solid LY11 Alloy by SIMA, J. Mater. Eng. Perform., 2003, 12, p 249–253

Y.L. Lu, M.Q. Li, and X.C. Li, Experimental Investigation and Modeling of Microstructural Variables of the Al-4Cu-Mg Alloy, Mater. Sci. Technol., 2008, 24(7), p 815–821

Acknowledgment

This research has been supported by the Foundational Research Plan of Jiangsu Province (No. BK2005025).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, Y., Li, M. & Li, X. Deformation Behavior and Constitutive Equation Coupled the Grain Size of Semi-Solid Aluminum Alloy. J. of Materi Eng and Perform 19, 1337–1343 (2010). https://doi.org/10.1007/s11665-010-9627-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9627-z