Abstract

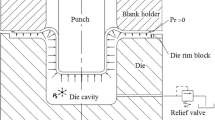

The importance of hydromechanical deep drawing is due to certain advantages over conventional deep drawing such as better formability, reduced number of manufacturing steps, improved surface finish, etc. Due to this, the potential applications of hydromechanical deep drawing have increased in the recent years. In this process, sheet metal parts are formed with the assistance of fluid pressure. The present work addresses the effect of sheet thickness and punch roughness on the formability of interstitial-free steel sheets in hydromechanical deep drawing. Experimental work has been done to study the influence of counter pressure on drawability by varying the sheet thickness and punch roughness. Finite element method has been used to simulate the process, and the results have been found to be in good agreement with the experimental results. It has been found out that the minimum required counter pressure for successful drawing increases with increase in sheet thickness. Drawability of 1.2 mm thick sheet improved with increase in punch roughness. As the punch roughness increases, the minimum required counter pressure decreases because of improved friction holding effect. For the same punch roughness, the minimum required counter pressure increases with increase in draw ratio.

Similar content being viewed by others

References

S.H. Zhang and J. Danckert, Development of Hydromechanical Deep Drawing, J. Mater. Process. Technol., 1998, 83, p 14–25

A. Kandil, An Experimental Study of Hydroforming Deep Drawing, J. Mater. Process. Technol., 2003, 134, p 70–80

K. Nakamura and T. Nakagawa, Sheet Metal Forming with Hydraulic Counter Pressure in Japan, Ann. CIRP, 1987, 36(1), p 191–194

K. Nakamura, H. Amino, and T. Nakagawa, Counter Pressure Deep Drawing and Its Applications in the Forming of Automobile Parts, J. Mater. Process. Technol., 1990, 23, p 243–265

S.H. Zhang, M.R. Jensen, J. Danckert, K.B. Nielsen, D.C. Kang, and L.H. Lang, Analysis of the Hydromechanical Deep Drawing of Cylindrical Cups, J. Mater. Process. Technol., 2000, 103, p 367–373

A. Fazli and B.M. Dariani, Theoretical and Experimental Analysis of the Axisymmetric Hydromechanical Deep Drawing, Proc. Inst. Mech. Eng., 2006, 220, p 1429–1437

J. Wu, R. Balendra, and Y. Qin, A Study on the Forming Limits of the Hydromechanical Deep Drawing of Components with Stepped Geometries, J. Mater. Process. Technol., 2004, 145, p 242–246

S.H. Zhang, M.R. Jensen, J. Danckert, K.B. Nielsen, D.C. Kang, and L.H. Lang, Effect of Anisotropy and Prebulging on Hydromechanical Deep Drawing of Mild Steel Cups, J. Mater. Process. Technol., 2003, 142, p 544–550

L.H. Lang, J. Danckert, and K.B. Nielsen, Analysis of Key Parameters in Sheet Hydroforming Combined with Stretch Forming and Deep Drawing, Proc. Inst. Mech. Eng., 2004, 218, p 845–855

L. Lang, J. Danckert, and K.B. Nielsen, Investigation into Hydrodynamic Deep Drawing Assisted by Radial Pressure, Part II: Numerical Analysis of the Drawing Mechanism and the Process Parameters, J. Mater. Process. Technol., 2005, 166, p 150–161

S.K. Singh and D. Ravikumar, Numerical Predictions of Limiting Draw Ratio and Thickness Variation in Hydromechanical Deep Drawing, Int. J. Mater. Product Technol., 2004, 21, p 106–123

S.K. Singh, A. Dixit, and D. Ravikumar, Optimization of the Design Parameters of Modified Die in Hydromechanical Deep Drawing Using LS-DYNA, Int. J. Adv. Manuf. Technol., 2008, 38, p 32–37

W.F. Hosford and R.M. Caddell, Metal Forming Mechanics and Metallurgy, 2nd ed., Printice Hall, New Jersey, 1993

F. Barlat and Lian, Plastic Behavior of and Stretchability of Sheet Metals. Part 1, Int. J. Plast., 1989, 5, p 51–66

S. Thiruvarudchelvan and W. Lewis, A Note on Hydroforming with Constant Fluid Pressure, J. Mater. Process. Technol., 1999, 88, p 51–56

S.K. Singh and D. Ravikumar, Effect of Process Parameters on Product Surface Finish and Thickness Variation in Hydromechanical Deep Drawing, J. Mater. Process. Technol., 2008, 204, p 169–178

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anil Kumar, A., Satapathy, S. & Ravi Kumar, D. Effect of Sheet Thickness and Punch Roughness on Formability of Sheets in Hydromechanical Deep Drawing. J. of Materi Eng and Perform 19, 1150–1160 (2010). https://doi.org/10.1007/s11665-010-9602-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9602-8