Abstract

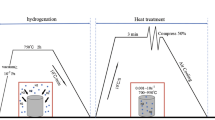

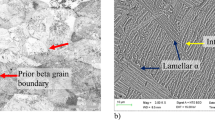

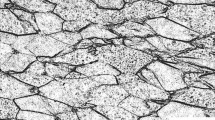

Isothermal compression of Ti-6Al-4V alloy without and with hydrogenation content of 0.27 wt.% was carried out on Gleeble-1500D thermal simulation machine at deformation temperature between 760 and 1000 °C and strain rate from 0.001 to 1 s−1. The experimental results show that hydrogenation can decrease the deformation temperature or increase the strain rate of Ti-6Al-4V alloy. The apparent activation energy was determined to be 667 kJ mol−1 for isothermal compression of the Ti-6Al-4V alloy without hydrogenation content of 0.27 wt.% in the α + β phase region (760-960 °C), and this value was about 655 and 199 kJ mol−1 for the alloy with 0.27 wt.% of hydrogenation content in the α + β phase region (760-840 °C) and β phase region (840-960 °C), respectively. Constitutive equation was developed for the high-temperature deformation of Ti-6Al-4V alloy both without and with hydrogenation content of 0.27 wt.%.

Similar content being viewed by others

References

F.H. Froes, O.N. Senkov, and J.I. Qazi, Hydrogen as a Temporary Alloying Element in Titanium Alloys: Thermohydrogen Processing, Int. Mater. Rev. 49, 2004, 227-245.

W.R. Kerr, R.R. Smith, M.E. Rosenblum, F.J. Gurney, Y.R. Mahajan, and L.R. Bidwell, Hydrogen as an Alloying Element in Titanium (HYDROVAC), Titanium 80: Science and Technology (Warrendale, PA), TMS, 1980, 4, p 2477–2486

N. Eliaz, D. Eliezer, D.L. Olson. Hydrogen-Assisted Processing of Materials. Mater. Sci. Eng., A289, 2000, 41-53.

V.A. Goltsov, Hydrogen Treatment (processing) of Materials: Current Status and Prospects, J. Alloy. Compd., 293-295, 1999, 844-857.

A.A. Ilyin, I.S. Polkin, A.M. Momonov, and V.K. Nosov, Thermohydrogen Treatment—The Base of Hydrogen Technology of Titanium Alloys, Titanium 95: Science and Technology (London), The Institute of Materials, 1995, 4, p 2462–2469

D. Elieaer, N. Eliaz, O.N. senkov, and F.H. Fores, Positive Effects of Hydrogen in Metals, Mater. Sci. Eng., A280, 2000, 220-224.

S.Q. Zhang, and L.R. Zhao, Effect of Hydrogen on the Superplasticity and Microstructure of Ti-6Al-4 V Alloy, J. Alloy. Compd., 218, 1995, 233-236.

O.N. Senkov, and J.J. Jonas, Effect of Phase Composition and Hydrogen Level on the Deformation Behavior of Titanium-Hydrogen Alloys. Metall. Mater. Trans., 27A, 1996, 1869-1876.

Y.Y. Lin, M.Q. Li, Y. Niu, and W.F. Zhang, Effect of Hydrogenation on the Microstructure During the Isothermal Compression of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo Alloy. Mater. Sci. Forum., 551-552, 2007, 417-420.

Y.Y. Lin, M.Q. Li, W.F. Zhang, and Y. Niu, Deformation Behavior in the Isothermal Compression of Hydrogenated Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo Alloy. J. Mater. Eng. Perform. 16, 2007, 93-96.

Y. Zhang, and S.Q. Zhang, Hydrogen Effects on High Temperature Deformation Characteristics of a Cast Ti-14Al-19Nb-3 V-2Mo Alloy, Scripta. Mater., l37, 1997, 1315-1321.

Y.X. Chen, X.J. Wan, F. Li, Q.J. W, and Y.Y. Liu, The Behavior of Hydrogen in High Temperature Titanium alloy Ti-60. Mater. Sci. Eng., A466, 2007, 156-159.

S.L. Semiantin, and T.R. Bieler, The Effect of Alpha Platelet Thickness on Plastic Flow During Hot Working of Ti–6Al–4 V with a Transformed Miscrostructure, Acta. Mater., 49, 2001, 3565– 3573.

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier and P.V.R.K Prasad, Microstructural Mechanisms During Hot Working of Commercial Grade Ti-6Al-4 V with Lamellar Starting Structure, Mater. Sci. Eng., A325, 2002, 112-125.

S. Tamirisakandala, B.V. Vedam, and R.B. Bhat. Recant Advances in the Deformation Processing of Titanium alloys. J. mater. Eng. Perform., 6, 2003, 661-673.

J.I. Qazi, O.N. Senkov, J. Rahim, A. Genc, and F.H. Fores, Phase Transformations in Ti-6Al-4 V-xH Alloys, Metall. Mater. Trans., 32A, 2001, 2453-2463.

P. Wanjara, M. JaHazi, H. Monajati, S. Yue, and J.P. Immarigeon, Hot Working Behavior of Near-Alpha Alloy IMI834, Mater. Sci. Eng., A396, 2005, 50-60.

C.M. Sellars, and W.J. Tegart, Acta. Metall., 14, 1966, 1136-1138.

R. Ding, Z.X. Guo, and A. Wilson, Microstructural Evolution of a Ti-6Al-4 V Alloy During Thermomechanical Processing, Mater. Sci. Eng., A 327, 2002, 233-245.

Acknowledgments

The authors thank the financial supports from the National Natural Science Foundation of China with Grant No. 50371068, and the Aviation Scientific Foundation of AVIC with Grant No. 05H53058.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niu, Y., Li, M., Hou, H. et al. High-Temperature Deformation Behavior of Ti-6Al-4V Alloy without and with Hydrogenation Content of 0.27 wt.%. J. of Materi Eng and Perform 19, 59–63 (2010). https://doi.org/10.1007/s11665-009-9427-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9427-5