Abstract

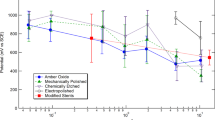

Current methods to evaluate the corrosion resistance of small medical implants are typically based on short-term in vitro tests. While the duration of these tests is kept to a minimum to make it feasible to evaluate a large number of samples in a reasonable time, these methods do not account for the long-term changes that can occur in the oxides of metals exposed to biological fluids. Given other electrochemical changes to these materials with time in solution, it is a reasonable question to consider whether breakdown potentials are a fundamental parameter of a material and surface condition. Data on 316L and nitinol wire samples, and nitinol stents, show that breakdown potentials increase with time in solution up to 28 days. The difference between the breakdown potential and rest potentials either increased or exhibited no change.

Similar content being viewed by others

References

Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptability of Small Implant Devices, F2129-06, ASTM International, 2006

Standard Test Method for Pitting and Crevice Corrosion of Metallic Surgical Implant Materials, F746-04, ASTM International, 2004

Standard Guide for Conducting and Evaluating Galvanic Corrosion Tests in Electrolytes, G71-83, ASTM International, 2003

R.A. Corbett, Laboratory Corrosion Testing of Medical Implants, Proceedings of the Materials and Processes for Medical Devices Conference, S. Shrivastava, Ed., Sept 8-10, 2003 (Anaheim), ASM International, 2004, p 133–138

S.N. Rosenbloom and R.A. Corbett, An Assessment of ASTM F2129 Test Results Comparing Nitinol to Other Implant Alloys, Proceedings of the International Conference on Shape Memory and Superelastic Technologies, B. Berg, M.R. Mitchell, and J. Proft, Eds., May 7-11, 2006 (Pacific Grove, CA), ASM International, 2008, p 243–251

T.P. Hoar, D.C. Mears, Corrosion-Resistant Alloys in Chloride Solutions: Materials for Surgical Implants, Proc. Royal Soc. London, Series A: Mathematical and Physical Sciences, 294, p 486–510 (1966)

C.C. Shih, S.J. Lin, K.H. Chung, Y.L. Chen, Y.Y. Su, Increased Corrosion Resistance of Stent Materials by Converting Current Surface Film of Polycrystaline Oxide Into Amorphous Oxide. J. Biomed. Mater. Res., 52, p 323–332 (2000)

B.G. Pound, Susceptability of Nitniol to Localized Corrosion, J. Biomed. Mater. Res., 77A, p 185–191 (2006)

B.E. Wilde, E. Williams, The Use of Current/Voltage Curves for the Sstudy of Localized Corrosion and Passivity Breakdown on Stainless Steels in Chloride Media, Electrochem. Acta, 16, p 1971-1985 (1971)

D.C. Silverman, Tutorial on Cyclic Potentiodynamic Polarization Technique, paper no. 299, Corrosion 1998 (Houston, TX), NACE International, p 1179–1225 (2003)

N. Istephanous, Z. Bai, J.L. Gilbert, K. Rohly, A. Belu, I. Trausch, D. Untereker, Oxide Films on Metallic Biomaterials: Myths, Facts and Opportunities, Mat. Sci. Forum, 426-432, p 3157–3164 (2003)

J.P. Bearinger, C.A. Orme, and J.L. Gilbert, In Situ Imaging and Impedance Measurements of Titanium Surfaces Using AFM and SPIS, Biomaterials, 24, p 1837-1852 (2003)

J. Bai and J.L. Gilbert, In Situ Electrochemical Atomic Force Microscopy Study of Morphology of Oxide Film on Etched NITI Alloy: Effects of Hydration and Potential, World Congress of Biomaterials, Sydney, 2004

G. Rondelli, P. Torricelli, M. Fini, L. Rimondini, R. Giardino, In Vitro Corrosion Study by EIS of an Equiatomic NiTi Alloy and Iimplant Quality AISI Stainless Steel, J. Biomed. Mater. Res. Part B: Appl. Biomater., 79B, p 320–324 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at Shape Memory and Superelastic Technologies 2008, held September 21-25, 2008, in Stresa, Italy, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Warner, C.P. The Effect of Exposure to Simulated Body Fluids on Breakdown Potentials. J. of Materi Eng and Perform 18, 754–759 (2009). https://doi.org/10.1007/s11665-009-9404-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9404-z