Abstract

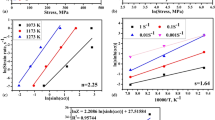

A thermo-mechanical model has been developed to establish a coupled heat conduction and plastic flow analysis in hot-rolling process. This model is capable of predicting temperature, strain, and strain rate distributions during hot rolling as well as the subsequent static recrystallization fraction and grain size changes after hot deformation. Finite element and neural network models are coupled to assess recrystallization kinetics after hot rolling. A new algorithm has been suggested to create differential data sets to train the neural network. The model is then used to predict histories of various deformation variables and recrystallization kinetics in hot rolling of AA5083. Comparison between the theoretical and the experimental data shows the validity of the model.

Similar content being viewed by others

References

Toloui M., Serajzadeh S., Modelling recrystallization kinetics during hot rolling of AA5083, J. Mater. Process. Technol. 2007; 184: 345-353.

Li X, Wang M, Dua F, A coupling thermal mechanical and microstructural FE model for hot strip continuous rolling process and verification, Mater. Sci. Eng. A 2005; 408: 33-41.

Serajzadeh S, A model for prediction of flow behavior and temperature distribution during warm rolling of a low carbon steel, Materials and Design 2006; 27: 529-534.

Pietrzyk M, FE Based Model of Structure Development in the Hot Rolling Process, Steel Res. 1990; 61: 603-607.

Reti T, Felde I, A non-linear extension of the additivity rule, Computational Materials Science 1999; 15: 466-482.

Christian JW 1975 The theory of transformations in metals and alloys. 2nd ed, Oxford: Pergamon Press, pp 545-546.

Johnson W. A., Mehl R.F 1939 Reaction kinetics in processes of nucleation and growth. Trans. Amer. Inst. Mining Metall. Engin 135: 416-442.

Dobrza′nski LA, Trzaska J 2004 Application of neural networks to forecasting the CCT diagrams, Journal of Materials Processing Technology 157-158: 107-13.

Malinov S, Sha W and Guo Z, Application of artificial neural network for prediction of time-temperature-transformation diagrams in titanium alloys, Materials Science and Engineering A, 2000; 283: 1-10.

Sterjovski Z, Nolan D, Carpenter KR, Dunne DP, Norrish J, Artificial neural networks for modelling the mechanical properties of steels in various applications, Journal of Materials Processing Technology 2005; 30: 536-544.

Kobayashi S, Oh SI, Metal Forming and the Finite Element Method, Oxford University Press, Oxford, 1989.

Lenard JG, Pietrzyk M and Cser L, Mathematical and Physical Simulation of the properties of Hot Rolled Products, Elsevier Science Ltd., Oxford, 1999.

Hagan M T, Demuth H B and Beale M, Neural Network Design, PWS publishing company, Boston, 2002.

T. Sheppard, M.A. Zaidi, P.A. Hollinshead, and N. Raghunathan, Structural evolution during the rolling of Aluminium alloys, in Microstructural Control in Aluminium Alloys: Deformation, Recovery and Recrystallization, E.H. Chia, and H.J. McQueen, Eds., New York, 27 February 1985, The Metallurgical Society Inc., 1986, p 19–43.

Chen BK, Thomson PF, Choi SK 1992 Computer modeling of microstructure during hot flat rolling of aluminum, Mater. Sci. Technology 8: 72-77.

Ahmed H, Wells M A, Maijer D M, Howes B J and Van Der Winden M R, Modelling of microstructure evolution during hot rolling of AA5083 using an internal state variable approach integrated into an FE model, Materials Science and Engineering 2005; A390: 278-290.

Sellars CM, Modeling microstructural development during hot rolling, Mater. Sci. Technology 1990; 6: 1072-1081.

Vetrano JS, Lavender CA, Hamilton CH, Smith MT and Bruemmer SM, Superplastic behavior in a commercial 5083 aluminum alloy, Scripta Metallurgica et Materialia 1994; 30: 565-570.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Seyed Salehi, M., Serajzadeh, S. A Model to Predict Recrystallization Kinetics in Hot Strip Rolling Using Combined Artificial Neural Network and Finite Elements. J. of Materi Eng and Perform 18, 1209–1217 (2009). https://doi.org/10.1007/s11665-009-9359-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9359-0