Abstract

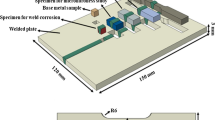

Commercially pure titanium (Ti) has been selected for the fabrication of dissolver for the proposed fast reactor fuel reprocessing plant at Kalpakkam, India. In the present investigation, microstructural changes and corrosion behavior of tungsten inert gas (TIG) welds of Ti grade-1 and grade-2 with different heat inputs were carried out. A wider heat affected zone was observed with higher heat inputs and coarse grains were observed from base metal toward the weld zone with increasing heat input. Fine and more equiaxed prior β grains were observed at lower heat input and the grain size increased toward fusion zone. The results indicated that Ti grade-1 and grade-2 with different heat inputs and different microstructures were insensitive to corrosion in liquid, vapor, and condensate phases of 11.5 M nitric acid tested up to 240 h. The corrosion rate in boiling liquid phase (0.60-0.76 mm/year) was higher than that in vapor (0.012-0.039 mm/year) and condensate phases (0.04-0.12 mm/year) of nitric acid for Ti grade-1 and grade-2, as well as for base metal for all heat inputs. Potentiodynamic polarization experiment carried out at room temperature indicated higher current densities and better passivation in 11.5 M nitric acid. SEM examination of Ti grade-1 welds for all heat inputs exposed to liquid phase after 240 h showed corrosion attack on the surface, exposing Widmanstatten microstructure containing acicular alpha. The continuous dissolution of the liquid-exposed samples was attributed to the heterogeneous microstructure and non-protective passive film formation.

Similar content being viewed by others

References

Baldev Raj, U. Kamachi Mudali, Materials development and corrosion problems in nuclear fuel reprocessing plants, Progress in Nuclear Energy, 48, 283–313.

Baldev Raj, U. Kamachi Mudali, T. Jayakumar, KV. Kasiviswanathan, R. Natarajan Meeting the challenges related to material issues in chemical industries, Sadhana 25, 519–559 (2000)

U. Kamachi Mudali, R. K. Dayal, J.B. Gnanamoorthy Corrosion studies on materials of construction for spent nuclear fuel reprocessing plant equipment, Journal of Nuclear Materials, 203, 73–82 (1993)

A. Ravi Shankar, V.R. Raju, M. Narayana Rao, U. Kamachi Mudali, H·S. Khatak and Baldev Raj Corrosion of Zircaloy-4 and its Welds in Nitric Acid Medium, Corrosion Science, 9 (49),3527–3538 (2007)

A. Ravi Shankar, R.K. Dayal, R. Balasubramaniam, V.R. Raju, R. Mythili, S. Saroja, M. Vijayalakshmi and VS. Raghunathan Effect of Heat Treatment on the Corrosion Behaviour of Ti-5Ta-1.8Nb alloy in Boiling Concentrated Nitric Acid, Journal of Nuclear Materials, 2–3 (372), 277–284 (2008)

T. Karthikeyan, A. Dasgupta, S. Saroja, M. Vijayalakshmi, and V.S. Raghunathan, Studies on Weldability of Ti-5Ta-2Nb Alloy for Reprocessing Plant Applications, Proceedings of the Conference on Materials and Technologies for Nuclear Fuel Cycle (Covering Materials, Robotics, Process Instrumentation and Inspection Technologies), SERC, Chennai, Dec 15–16, 2003

Grant ken Hicken, Gas-Tungsten Arc Welding, ASM Handbook, Vol 6, Metals Park, OH, 1993

G.J. Guru Raja, Welding Titanium and Titanium Alloys—An Overview, International Workshop on Recent Trends in Welding, Bangalore, Oct 5–7, 1995

L.M. Gammon, R.D. Briggs, J.M. Packard, K.W. Batson, R. Boyer, and C.W. Domby, Metallography and Microstructures of Titanium and its Alloys, ASM Handbook, Vol 9, Metals Park, OH, p 899–917

Mathew Donachie J, Jr, Titanium a technical guide, ASM International, 2nd edition, Metals Park, Ohio, USA, 2000

W.A. Baeslack III, J.R. Davis, and C.E. Cross, Selection and Weldability of Conventional Titanium Alloys, ASM Handbook, Vol 6, Metals Park, OH, p 507–523

D.H. Phillips, Selection and Weldability of Advanced Titanium Base Alloys, ASM Handbook, Vol 6, Metals Park, OH, p 524–527

Corrosion of Non-Ferrous Alloy Weldments, ASM Handbook, Vol 13A, ASM international, Materials Park, OH, 2003, p 317–321

H.C. Dey, V. Shankar, C.R. Das, and A.K. Bhaduri, Weldability Study of Ti-Ta-Nb Alloy and Pure Ti, Proceedings of the Conference on Materials and Technologies for Nuclear Fuel Cycle (Covering Materials, Robotics, Process Instrumentation and Inspection Technologies), SERC, Chennai, Dec 15–16, 2003

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravi Shankar, A., Gopalakrishnan, G., Balusamy, V. et al. Effect of Heat Input on Microstructural Changes and Corrosion Behavior of Commercially Pure Titanium Welds in Nitric Acid Medium. J. of Materi Eng and Perform 18, 1116–1123 (2009). https://doi.org/10.1007/s11665-008-9335-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9335-0