Abstract

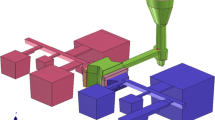

The aim of the present research is to identify the manufacturing factors that exert an active influence on the graphite phase formation in mottled Nihard cast irons constituting the roll shells of duplex work rolls processed by the double pour method during centrifugal casting. The studied rolls, referred to as alloy indefinite chill, were processed at industrial scale and had a core consisting of spheroidal graphite cast iron with a matrix of ferrite and pearlite. An additional aim of this study was to evaluate the effect and extent of these factors on the dynamic toughness response of the roll shell material.

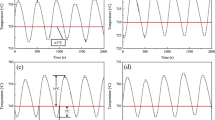

The research methodology employed consisted of the application of a saturated design of experiments with seven factors, eight experiments, and resolution III. The measured responses for graphite were: the volume fraction, count number per unit area, and morphology, determined by quantitative metallography. Impact testing was characterized by Charpy tests on U-notched specimens at 350 °C. The manufacturing factors studied were: the final weight percent of silicon, sulfur, and manganese; the liquidus and the casting temperatures; and, finally, inoculation with SiCaMn and A-type FeSi (with Zr).

The statistical experimental method conducted allowed us to confirm the significance of factors such as the %Si, the liquidus temperature and inoculation with SiCaMn on the precipitation of graphite in a white cast iron such as the Nihard irons used in the roll shell, in agreement with the precipitation of graphite in gray cast irons widely reported in the literature. It was also shown that the development of lamellar graphite shapes were favored by an increase in the total equivalent carbon and also by the increase in the amount of A-type FeSi added. Furthermore, the impact toughness was shown to improve with the increase in both the %Si and the liquidus temperature.

Similar content being viewed by others

References

British Rollmakers (China) Ltd., Alloy, Alloy Indefinite Chill (AIC) in Finishing Stand Rolls, http://www.brchina.com/about_brc.htm, Hong Kong (China)

J.A. Pero-Sanz, Propiedades generales de las fundiciones grises no aleadas (o de baja aleación) y grafito laminar, Fundiciones Férreas, 1st ed., S.A. Dossat, Ed., 1994 (Madrid), Gráficas ROA S.L., 1994, p 49–69, in Spanish

B.T.C. Nycen and T.P. Adams, Cast Iron Indefinite Roll produced by the Addition of Nb. US Patent 6013141, US, 2000

J.A. Pero-Sanz, Fundiciones Ni-hard, Fundiciones Férreas, 1st ed., S.A. Dossat, Ed., 1994 (Madrid), Gráficas ROA S.L., 1994, p 124–129, in Spanish

American Foundrymen’s Society Inc., Nodule Counts, Foundrymen’s Guide to Ductile Iron Microstructures, 1st ed., American Foundrymen’s Society, Inc., Ed., 1984 (Des Plaines, IL), AFS Press, 1994, p 27–31

A. Prat Bartés, X. Tort-Martorell Llabrés, P. Grima Cintas, and L. Pozueta Fernández, Construcción de diseños fraccionales y cálculo de las confusiones introducidas, Métodos Estadísticos, 2nd ed., UPC, Ed., 1997 (Barcelona), S.A. de Litografía, 2000, p 170–172, in Spanish

G.E.P. Box, W.G. Hunter, and J.S. Hunter, Concepto de resolución de un diseño, Estadística para Investigadores, 2nd ed., Reverté Ediciones S.A., Ed., 1999 (Méjico), Programas Educativos S.A. de C.V., 2002, p 396–401, in Spanish (translated with permission from John Wiley & Sons of the original book entitled, Statistics for Experimenters. An introduction to Design, Data Analysis and Model Building)

G.F. Vander Voort (1984) Quantitative Microscopy, Metallography Principles and Practice, 1st ed., McGraw-Hill, Inc., Ed., 1984 (New York), Jay’s Publishers Services, p 410–502

Comité Técnico ECIIS/TC1a, “Ensayo de flexión por choque sobre probetas Charpy. Parte 1: Método de ensayo”, EN 10 045-1, European Committee for Standardization-AENOR, Ensayos de Materiales, p 1–14, in Spanish

G.E.P. Box, W.G. Hunter, and J.S. Hunter, Apéndice 10A-Algoritmo de Yates, Estadística para Investigadores, 2nd ed., S.A. Reverté Ediciones, Ed., 1999 (Méjico), Programas Educativos S.A. de C.V., 2002, p 355–360, in Spanish (translated with permission from John Wiley & Sons, Statistics for Experimenters. An introduction to Design, Data Analysis and Model Building)

Acknowledgments

The authors wish to thank the University of Oviedo Vice-Rectorate for Research for providing economic support to carry out the proof-reading of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asensio-Lozano, J., Álvarez-Antolín, J.F. Saturated Fractional Design of Experiments: Toughness and Graphite Phase Optimizing in Nihard Cast Irons. J. of Materi Eng and Perform 17, 216–223 (2008). https://doi.org/10.1007/s11665-007-9138-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9138-8