Abstract

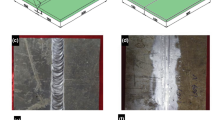

This article reports the effect of postweld aging treatment on fatigue behavior of pulsed current welded AA 7075 aluminum alloy joints. AA7075 aluminum alloy (Al-Zn-Mg-Cu alloy) has gathered wide acceptance in the fabrication of light weight structures requiring high strength-to weight ratio, such as transportable bridge girders, military vehicles, road tankers, and railway transport systems. The preferred welding processes of AA7075 aluminum alloy are frequently gas tungsten arc welding (GTAW) process and gas metal arc welding (GMAW) process due to their comparatively easier applicability and better economy. Weld fusion zones typically exhibit coarse columnar grains because of the prevailing thermal conditions during weld metal solidification. This often results inferior weld mechanical properties and poor resistance to hot cracking. In this investigation, an attempt has been made to refine the fusion zone grains by applying pulsed current welding technique. Rolled plates of 10 mm thickness have been used as the base material for preparing multipass welded joints. Single V butt joint configuration has been prepared for joining the plates. The filler metal used for joining the plates is AA 5356 (Al-5Mg (wt.%)) grade aluminum alloy. Four different welding techniques have been used to fabricate the joints and they are: (i) continuous current GTAW (CCGTAW), (ii) pulsed current GTAW (PCGTAW), (iii) continuous current GMAW (CCGMAW), and (iv) pulsed current GMAW (PCGMAW) processes. Argon (99.99% pure) has been used as the shielding gas. Rotary bending fatigue testing machine has been used to evaluate fatigue behavior of the welded joints. Current pulsing leads to relatively finer and more equi-axed grain structure in GTA and GMA welds. Grain refinement is accompanied by an increase in fatigue life and endurance limit. Simple postweld aging treatment applied to the joints is found to be beneficial to enhance the fatigue performance of the welded joints.

Similar content being viewed by others

References

V.V. Yakubovski and I.I. Valteris, Geometrical Parameters of Butt and Fillet Welds and their Influence on the Welded Joint Fatigue Life, IIW Doc. No. XIII, 1989, p 1326–1369, in English

C. Miki and M. Sukano, A Survey of Fatigue Cracking Experience Steel Bridges, Int. Inst. Welding IIW Doc XIII, 1990, p 1383–1390, in English

S.J. Maddox, Review of Fatigue Assessment Procedures for Welded Aluminium Structures, Int. J. Fatigue, 2003, p 1359–1378, in English

H.T. Kim and S.W. Nam, Solidification Cracking Susceptibility of High Strength Aluminium Alloy Weldment, Scr. Mater., 1996, p 1139–1145, in English

G.D. Janaki Ram, T.K. Mitra, V. Shankar, Microstructural Refinement Through Inoculation of Type 7020 Al-Zn-Mg Alloy Welds and its Effect on Hot Cracking and Tensile Property, J. Mater. Process. Technol., 142, 2003, p 174–181, in English

T. Mohandoss, G. Madhusudhan Reddy, Effect of Frequency of Pulsing in Gas Tungsten Arc Welding on the Microstructure and Mechanical Properties of Titanium Alloy Welds, J. Mater. Sci. Lett., 15, 1996, p 626–628, in English

D.A. Shelwatker, G. Madhusudhan Reddy and A.A. Gokhale, Gas Tungsten Arc Welding Studies on Similar and Dissimilar Combinations of Al-Zn-Mg Alloy RDE 40 and Al-Li Alloy 1441, Sci. Technol. Weld. Join., 2002, p 352–361, in English

G.E. Dieter, Mechanical Metallurgy, 2nd ed., McGraw-Hill, 1988

R. Jaccard, Fatigue Crack Propagation in Aluminium, IIW Doc XIII, 1990, p 1377–1390, in English

T. Shinoda, Y. Ueno, I. Masumoto, Effect of Pulsed Welding Current on Solidification Cracking in Austenitic Stainless Steel Welds, Trans. Jpn. Welding Soc., 21, 1990, p 18–23, in English

G. Madhusudhan Reddy, P. Sammaiah, C.V.S Murty and T. Mohandas, Influence of Welding Techniques on Microstructure and Mechanical Properties of AA 6061 (Al-Mg-Si) GTA Welds, Proc. Int. Welding Conference, Feb 14-16, 1999 (New Delhi), Indian Institute of Welding, 1999, p 33–46

G. Madhusudhan Reddy, A.A. Gokhale, K. Prasad Rao, Optimization of Pulse Frequency in Pulsed Current Gas Tungsten Arc Welding of Aluminium-Lithium Alloy Sheets, J. Mater. Sci. Technol., 14, 1998, p 61–66, in English

P.K. Ghosh, V. Sharma, Chemical Composition and Microstructure in Pulsed MIG Welded Al-Zn-Mg Alloy, J. Mater. Trans., 32, 1991, p 145–150, in English

N.B. Potluri, P.K. Ghosh, P.C. Gupta and Y.S. Reddy, Studies on Weld Metal Characteristics and Their Influences on Tensile and Fatigue Properties of Pulsed Current GMA Welded Al-Zn-Mg Alloy, Welding Res. Suppl., 1996, p 62s–70s, in English

L.K. Berg, V. Hansen, GP-Zones in Al-Zn-Mg Alloys and Their Role in Artificial Aging, Acta Mater., 49, 2001, p 3443–3451, in English

L.F. Mondolfo, Aluminium Alloys—Structure and Properties, 3rd ed., Butterworths, London, 1997

C. Eripret, P. Hornet, Prediction of Overmatching Effects on the Fracture of Stainless Steel Cracked Welds, Mis-Matching of Welds, 1994; ESIS 17, K.H. Schwalbe, M. Kocak, Mechanical Engineering Publications (London), p 685–708

D.C. Lin, T.S. Wang, T.S. Srivatsan, A Mechanism for the Formation of Equiaxed Grains of Aluminium-Lithium Alloy 2090, Mater. Sci. Eng. A 335, 2003, p 304–309, in English

R.W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, Wiley, 1983

H.O. Fuchs and R.I. Stephens, Metal Fatigue in Engineering, Wiley, 1980

S.E. Stanzn-Tschegg, O. Plasser, E.K. Tschegg, A.K. Vasudevan, Influence of Microstructure and Load Ratio on Fatigue Threshold Behaviour in 7075 Alloys, Int. J. Fatigue, 21, 1999, p s255–s262, in English

S. Suresh, A.K. Vasudevan, P.E. Bretz, Mechanisms of Slow Fatigue Crack Growth in High Strength Aluminium Alloys, Role of Microstructure and Environment, Metall. Trans. A, 15, 1984, p 369–378, in English

Acknowledgements

The authors are grateful to the Department of Manufacturing Engineering, Annamalai University, Annamalainagar, Tamil Nadu, India for extending the facilities of Metal Joining Laboratory and Materials Testing Laboratory to carryout this investigation. The authors also wish to express their sincere thanks to Directorate of Extramural Research & Intellectual Property Rights, Defence Research & Development Organisation (DRDO), New Delhi for the financial support to carryout this investigation through sponsored project No. ERIP/ER/0203351/M/01/633. The first two authors are very grateful to the third author, Dr. G. Madhusudhana Reddy, Scientist-F, Defence Metallurgical Research Laboratory (DMRL), Hyderabad for his valuable suggestions, guidance and discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balasubramanian, V., Ravisankar, V. & Madhusudhan Reddy, G. Effect of Postweld Aging Treatment on Fatigue Behavior of Pulsed Current Welded AA7075 Aluminum Alloy Joints. J. of Materi Eng and Perform 17, 224–233 (2008). https://doi.org/10.1007/s11665-007-9129-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9129-9