Abstract

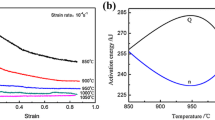

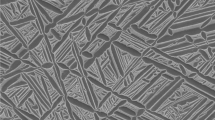

A superplastic Ti-6Al-4V grade has been deformed at a strain rate of 5 × 10−4 s−1 and at temperatures up to 1050 °C. Structural mechanisms like grain boundary sliding, dynamic recrystallization, and dynamic grain growth, occurring during deformation, have been investigated and mechanical properties such as flow stress, strain hardening, and strain at rupture have been determined. Dynamic recrystallization (DRX) brings on a decrease in the grain size. This could be of great interest because a smaller grain size allows a decrease in temperature for superplastic forming. For DRX, the driving force present in the deformed microstructure must be high enough. This means the temperature must be sufficiently low to ensure storing of enough dislocation energy but must also be high enough to provide the activation energy needed for DRX and to allow superplastic deformation. The best compromise for the temperature was found to be situated at about 800 °C; this is quite a bit lower than the 925 °C referenced in the literature as the optimum for the superplastic deformation. At this medium temperature the engineering strain that could be reached exceeds 400%, a value high enough to ensure the industrial production of complex parts by the way of the superplastic forming. Microstructural, EBSD, and mechanical investigations were used to describe the observed mechanisms, some of which are concurrent.

Similar content being viewed by others

References

C. Leyens and M. Peters, Titanium and titanium alloys, Chichester (England): John Wiley & Son Inc., 2003, p 333–350

D.H. Avery, W.A. Backofen, “A Structural Basis for Super-plasticity,” Trans. Am. Soc. Met., 1965, 58, p 551-562

R.H. Johnson, “Superplasticity,” Metall. Rev., 1970, 146, p 115–134

W.B. Morrison, “The elongation of superplastic alloys,” Trans. Am. Inst. Min. Metall. Pet. Eng., 1968, 242, p 2221–2227

A.K. Ghosh, C.H. Hamilton, “Mechanical Behaviour and Hardening Characteristics of a Superplastic Ti-6Al-4V alloy,” Metall. Trans. A, 1979, 10A, p 699-706

B.H. Cheong, J. Lin, A.A. Ball, “Modelling of Hardening Due to Grain Growth for a Superplastic Alloy,” J. Mater. Process. Technol. 2001, 119, p 361-365

C.H. Johnson, S.K. Richter, C.H. Hamilton, J.J. Hoyt, “Static Grain Growth in a Microduplex Ti–6Al–4V Alloy,” Acta Mater., 1999, 47(1), p 23-29

D. Katrakova, M.J. Damgaard, F. Mücklich, “Structures of Trihydroxynaphthalene Reductase-Fungicide ComplexesImplications for Structure-Based Design and Catalysis,” Structure, 2001, 38, p 19-24

X.J. Zhu, M.J. Tan, W. Zhou, “Enhanced Superplasticity in Commercially Pure Titanium Alloy,” Scripta Mater., 2005, 52(7), p 651-655

M.L. Meier, D.R. Lesuer, A.K. Mukherjee, “The Effects of the α/β Phase Proportion on the Superplasticity of Ti-6Al-4V and Iron-Modified Ti-6Al-4V,” Mater. Sci. Eng. A 1992, 154(2), p 165-173

J.S. Kim, J.H. Kim, Y.T. Lee, C.G. Park, C.S. Lee, “Microstructural Analysis on Boundary Sliding and its Accommodation Mode during Superplastic Deformation of Ti–6Al–4V Alloy,” Mater. Sci. Eng. A, 1992, 263(2), p 272-280

P. Van Houtte: The MTM-FHM Software System Version 2, Users Manual, 1995

Acknowledgments

This work was carried out in the frame of the “Inter University Attraction Poles program-Belgian Science Policy” under contract number IUAP P5-08, as well as the research project MX-03 of the BE Army Staff.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was presented at the AeroMat Conference, International Symposium on Superplasticity and Superplastic Forming (SPF) held in Seattle, WA, June 6-9, 2005.

Rights and permissions

About this article

Cite this article

Vanderhasten, M., Rabet, L. & Verlinden, B. Deformation Mechanisms of Ti-6Al-4V During Tensile Behavior at Low Strain Rate. J. of Materi Eng and Perform 16, 208–212 (2007). https://doi.org/10.1007/s11665-007-9033-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9033-3