Abstract

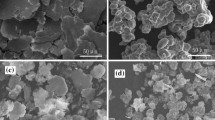

Flaky microwave absorbing materials based on Ce2Co17 with different addition of Ni content were fabricated successfully using the method of vacuum arc melting and high energy ball milling. The phase structure, grain morphology, electromagnetic parameters and reflection loss (RL) were probed by the corresponding equipment and computational simulation software. The RL values of Ce2Co17−xNix alloys that exceeded − 10 dB were observed in the frequency range of 6.16–10.24 GHz with a thickness of only 1.8 mm. Besides, via adjusting the thickness to only 1.6 mm, the minimum RL of Ce2Co16.6Ni0.4 powder was as high as − 44.29 dB at 9.6 GHz with a broad bandwidth of 3.04 GHz. Furthermore, the different weight ratio for Ce2Co16.6Ni0.4/carbonyl iron powder composite was also studied. The microwave absorption peak of composite shifts to a higher frequency region with the increasing weight ratio of carbonyl iron powder. More importantly, the effective bandwidth of the composite with the Ce2Co16.6Ni0.4/carbonyl iron powder weight ratio of 50:50 can be obtained at about 4.64 GHz, manifesting that composite can be provided with excellent microwave absorption bandwidth by adjusting the weight ratio of carbonyl iron powder.

Similar content being viewed by others

References

J. Sun, H.L. Xu, Y. Shen, H. Bi, W.F. Liang, and R.B. Yang, J. Alloys Compd. 548, 18 (2013).

J. Li, G.Z. Xie, P.C. Ji, J. Qu, J.W. Chen, and J. Chen, J. Magn. Magn. Mater. 443, 85 (2017).

C. Liu, Y. Yuan, J.T. Jiang, Y.X. Gong, and L. Zhen, J. Magn. Magn. Mater. 395, 152 (2015).

W.C. Li, J.J. Lv, X. Zhou, J.W. Zheng, Y. Ying, L. Qiao, J. Yu, and S.L. Che, J. Magn. Magn. Mater. 426, 504 (2017).

A. Xia, S. Ren, J. Lin, Y. Ma, C. Xu, J. Li, C. Jin, and X. Liu, J. Alloys Compd. 653, 108 (2015).

I.S. Maksymov and M. Kostylev, J. Appl. Phys. 116, 173905 (2014).

K.S. Nakayama, T. Chiba, S. Tsukimoto, Y. Yokoyama, T. Shima, and S. Yabukami, Appl. Phys. Lett. 105, 202403 (2014).

J. Zhou, Z.H. Zhou, and C. Xiong, J. Electron. Mater. 47, 1244 (2018).

Y. Lin, P. Kang, H.B. Yang, and M. Liu, J. Alloys Compd. 644, 390 (2015).

Y. Liu, X. Liu, and R. Li, RSC Adv. 5, 8713 (2014).

M.A. Ahmed, N. Okasha, and R.M. Kershi, J. Magn. Magn. Mater. 320, 1146 (2008).

X.G. Huang, J. Chen, L.X. Wang, and Q.T. Zhang, Rare Met. 30, 44 (2011).

Z. Mosleh, P. Kameli, A. Poorbaferani, M. Ranjbar, and H. Salamati, J. Magn. Magn. Mater. 397, 101 (2016).

Z.Q. Qiao, S.K. Pan, J.L. Xiong, L.C. Cheng, and Q.R. Yao, J. Mater. Sci.: Mater. Electron. 27, 7487 (2016).

Z.Q. Cui and Y.C. Qin, Metallography and Heat Treatment, 2nd ed. (Beijing: China Machine Press, 2007), pp. 37–52.

X. Wu, H. Luo, and Y. Wan, Mater. Lett. 92, 139 (2013).

X.Y. Fang, M.S. Cao, X.L. Shi, and Z.L. Hou, J. Appl. Phys. 107, 054304 (2010).

W.Q. Zhang, S.W. Bie, H.C. Chen, Y. Lu, and J.J. Jiang, J. Magn. Magn. Mater. 358–359, 1 (2014).

C.K. Zhang, J.J. Jiang, S.W. Bie, L. Zhang, L. Miao, and X.X. Xu, J. Alloys Compd. 527, 71 (2012).

S.b. Liao, Ferromagnetic, 2nd ed. (Beijing: Science Press, 1988), pp. 3–88.

L. Zhen, Y.X. Gong, J.T. Jiang, and W.Z. Shao, J. Appl. Phys. 104, 034312 (2017).

J.R. Ma, X.X. Wang, W.Q. Cao, H. Chen, H.J. Yang, J. Yuan, and M.S. Cao, Chem. Eng. J. 339, 487 (2018).

Y.Z. Yang, Z.T. Kang, and D. Chen, J. Mater. Sci.: Mater. Electron. 25, 4246 (2014).

B.S. Zhang, Y. Feng, J. Xiang, Y. Yang, and H.X. Lu, IEEE Trans. Magn. 42, 1778 (2006).

X.Y. Fang, M.S. Cao, and X.L. Shi, J. Appl. Phys. 107, 054304 (2010).

R.C. Hu, G.G. Tan, X.S. Gu, S.W. Chen, C.G. Wu, Q.K. Man, C.T. Chang, X.M. Wang, R.W. Li, S.L. Che, and L.Q. Jiang, J. Alloys Compd. 730, 255 (2018).

X.X. Wang, T. Ma, J.C. Shu, and M.S. Cao, Chem. Eng. J. 332, 321 (2018).

Y. Liu, Y.Y. Li, F. Luo, X.L. Su, J. Xu, J.H. Wang, X.H. He, and Y.M. Shi, J. Mater. Sci.: Mater. Electron. 28, 6622 (2017).

Acknowledgments

Project supported by the National Natural Science Foundation of China (51361007), 2017 director fund of Guangxi Key Laboratory of Wireless Wideband Communication and Signal Processing (GXKL06170107) and Innovation Project of GUET Graduate Education (2018YJCX87).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, Y., Pan, S., Cheng, L. et al. Improving Microwave Absorbing Property of Flaky Ce2Co17 Alloys by Ni Content and Carbonyl Iron Powder. J. Electron. Mater. 48, 1574–1581 (2019). https://doi.org/10.1007/s11664-018-06868-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-06868-y