Abstract

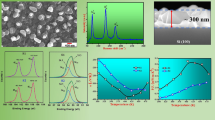

In this work, flexible Bi x Te y thin films were prepared by radio frequency (RF) magnetron sputtering using a Bi2Te3 target on polyimide substrate. The effects of sputtering pressures, which ranged between 0.6 Pa and 1.6 Pa on the [Bi]:[Te] ratio, and structural and thermoelectric properties were investigated. The [Bi]:[Te] ratio of thin film was determined by energy-dispersive spectrometry (EDS). The EDS spectra show the variation of the [Bi]:[Te] ratio as the sputtering pressure is varied. The film deposited at 1.4 Pa almost has a stoichiometric composition. The selective films with different [Bi]:[Te] ratios and sputtering pressures were characterized by their surface morphologies, crystal and chemical structures by field emission scanning electron microscopy (FE-SEM), x-ray diffraction (XRD) and Raman spectroscopy, respectively. Electrical transport properties, including carrier concentration and mobility, were measured by Hall effect measurements. Seebeck coefficients and electrical conductivities were simultaneously measured by a direct current four-terminal method (ZEM-3). The XRD and Raman spectroscopy results show a difference in microstructure between BiTe and Bi2Te3 depending on the [Bi]:[Te] ratio. Electrical conductivity and Seebeck coefficient are related to the crystal and chemical structures. The maximum power factor of the Bi2Te3 thin film is 9.5 × 10−4 W/K2 m at room temperature, and it increases to 12.0 × 10−4 W/K2 m at 195°C.

Similar content being viewed by others

References

Y. Deng, H.-M. Liang, Y. Wang, Z.-W. Zhang, M. Tan, and J.-L. Cui, J. Alloys Compd. 509, 5683 (2011).

C. Zhao-kun, F. Ping, Z. Zhuang-hao, L. Peng-juan, C. Tian-bao, C. Xing-min, L. Jing-ting, L. Guang-xing, and Z. Dong-ping, Appl. Surf. Sci. 280, 225 (2013).

L.M. Goncalves, C. Couto, P. Alpuim, A.G. Rolo, F. Völklein, and J.H. Correia, Thin Solid Films 518, 2816 (2010).

L.M. Goncalves, P. Alpuim, G. Min, D.M. Rowe, C. Couto, and J.H. Correia, J. Vac. 82, 1499 (2008).

A. LiBassi, A. Bailini, C.S. Casari, F. Donati, A. Mantegazza, M. Passoni, V. Russo, and C.E. Bottani, J. Appl. Phys. 105, 124307 (2009).

H.J. Lee, S. Hyun, H.S. Park, and S.W. Han, Microelectron. Eng. 88, 593 (2011).

X. Wang, H. He, N. Wang, and L. Miao, Appl. Surf. Sci. 276, 539 (2013).

Z.H. Zheng, P. Fan, T.B. Chen, Z.K. Cai, P.J. Liu, G.X. Liang, D.P. Zhang, and X.M. Cai, Thin Solid Films 520, 5245 (2012).

P. Nuthongkum, A. Sakulkalavek, and R. Sakdanuphab, J. Electron. Mater. 46, 2900 (2017).

Y. Sun, E. Zhang, S. Johnsen, M. Sillassen, P. Sun, F. Steglich, J. Bøttiger, and B.B. Iversen, Thin Solid Films 519, 5397 (2011).

H. Feng-Hao, W. Na-Fu, T. Yu-Zen, C. Ming-Chieh, C. Yu-Song, and H. Mau-Phon, Appl. Surf. Sci. 280, 104 (2013).

R. Sathyamoorthy and J. Dheepa, J. Phys. Chem. Solids 68, 111 (2007).

T. Khumtong, P. Sukwisute, A. Sakulkalavek, and R. Sakdanuphab, J. Electron. Mater. 46, 3166 (2017).

V. Russo, A. Bailini, M. Zamboni, M. Passoni, C. Conti, C.S. Casari, A. LiBassi, and C.E. Bottani, J. Raman Spectrosc. 39, 205 (2008).

A. Sakulkalavek and R. Sakdanuphab, Mat. Sci. Semicon. Proc. 56, 313 (2016).

M. Cutler and N.F. Mott, Phys. Rev. 181, 1336 (1969).

O. Caha, A. Dubroka, J. Humlíček, V. Holý, H. Steiner, M. Ul-Hassan, J. Sánchez-Barriga, O. Rader, T.N. Stanislavchuk, A.A. Sirenko, G. Bauer, and G. Springholz, Cryst. Growth Des. 13, 3365 (2013).

H. Yue, A. Wu, Y. Feng, X. Zhang, and T. Li, Thin Solid Films 519, 5577 (2011).

S. Wang, G. Tan, W. Xie, G. Zheng, H. Li, J. Yang, and X. Tang, J. Mater. Chem. 22, 20943 (2012).

Z. Zeng, P. Yang, and Z. Hu, Appl. Surf. Sci. 268, 472 (2013).

J.R. Watling and D.J. Paul, J. Appl. Phys. 110, 114508 (2011).

Acknowledgements

The author would like to acknowledge the Faculty of Science, King Mongkut’s Institute of Technology Ladkrabang for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nuthongkum, P., Sakdanuphab, R., Horprathum, . et al. [Bi]:[Te] Control, Structural and Thermoelectric Properties of Flexible Bi x Te y Thin Films Prepared by RF Magnetron Sputtering at Different Sputtering Pressures. J. Electron. Mater. 46, 6444–6450 (2017). https://doi.org/10.1007/s11664-017-5671-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5671-x