Abstract

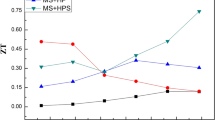

Three kinds of Sb1.6Bi0.4Te3.1 samples were prepared by the melt-spinning technique using quartz tubes with different nozzle’s diameters (1.0, 0.7 and 0.5 mm) to study the sensitivity of the thermoelectric properties to the variations of this parameter. The melt-spun ribbons were densified by spark plasma sintering (SPS). The melt-spun samples were characterized by powder x-ray diffraction and scanning electron microscopy. The dimensionless figures of merit (ZT) were calculated from the data obtained by measuring the Seebeck coefficient, electrical resistivity and thermal conductivity in the direction perpendicular to the uniaxial pressing direction of SPS. All ZT values for this set of samples were close to 1.0 around 380 K. The highest ZT value was obtained for the sample prepared using the largest nozzle diameter of 1.0 mm. Despite some variations in the carrier concentrations of the samples being observed, these results indicate a weak sensitivity of the melt-spun Sb1.6Bi0.4Te3.1 samples to the nozzle’s diameter during the melt-spinning process.

Similar content being viewed by others

References

B. Cantor, ed. Rapidly Quenched Met., Proc. Int. Conf., 3rd. (London: Metals Society, 1978), p. 480.

R.W. Cochrane and J.O. Strom-Olsen, eds., Rapidly Quenched Met., Proc. Int. Conf., 6th (London: Elsevier, 1988), p. 557.

T. Masumoto and K. Suzuki, eds., Rapidly Quenched Met., Proc. Int. Conf., 4th (Sendai: Japan Institute of Metals, 1982), p. 1451.

F. Sommer, S. Steeb, and H. Warlimont, eds., Rapidly Quenched Met., Proc. Int. Conf., 5th (Amsterdam: North-Holland, 1985), p. 1087.

Sh. Fan, J. Zhao, J. Guo, Q. Yan, J. Ma, and H.H. Hng, Appl. Phys. Lett. 96, 182104 (2010).

H. Li, X. Tang, Q. Zhang, and C. Uher, Appl. Phys. Lett. 94, 102114 (2009).

J.R. Salvador, R.A. Waldo, C.A. Wong, M. Tessema, D.N. Brown, D.J. Miller, H. Wang, A.A. Wereszczak, and W. Cai, Mater. Sci. Eng., B 178, 1087 (2013).

G. Tan, W. Liu, S. Wang, Y. Yan, H. Li, X. Tang, and C. Uher, J. Mater. Chem. A 1, 12657 (2013).

W. Xie, X. Tang, Y. Yan, Q. Zhang, and T.M. Tritt, J. Appl. Phys. 105, 113713 (2009).

W. Xie, X. Tang, Y. Yan, Q. Zhang, and T.M. Tritt, Appl. Phys. Lett. 94, 102111 (2009).

W. Xie, J. He, H.J. Kang, X. Tang, S. Zhu, M. Laver, S. Wang, J.R.D. Copley, C.M. Brown, Q. Zhang, and T.M. Tritt, Nano Lett. 10, 3283 (2010).

Ch.H. Kuo, Ch.Sh. Hwang, M.Sh. Jeng, W.Sh. Su, Y.W. Chou, and J.R. Ku, J. Alloys Compd. 496, 687 (2010).

J. Jiang, L. Chen, Sh. Bai, Q. Yao, and Q. Wang, Scripta Mater. 52, 347 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ohorodniichuk, V., Dauscher, A., Masschelein, P. et al. Investigation of the Nozzle Diameter as a Control Parameter of the Properties of Melt-Spun Sb2−x Bi x Te3 . J. Electron. Mater. 45, 1419–1424 (2016). https://doi.org/10.1007/s11664-015-4055-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-4055-3