Abstract

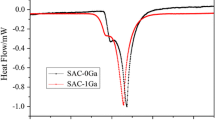

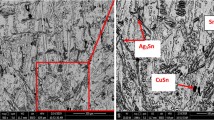

The aim of the present work is to develop a comparative evaluation of the microstructural and mechanical deformation behavior of Sn-Ag-Cu (SAC) solders with the minor addition of 0.05 wt.% Ni. Test results showed that, by adding 0.05Ni element into SAC solders, generated mainly small rod-shaped (Cu,Ni)6Sn5 intermetallic compounds (IMCs) inside the β-Sn phase. Moreover, increasing the Ag content and adding Ni could result in the change of the shape and size of the IMC precipitate. Hence, a significant improvement is observed in the mechanical properties of SAC solders with increasing Ag content and Ni addition. On the other hand, the tensile results of Ni-doped SAC solders showed that both the yield stress and ultimate tensile strengths decrease with increasing temperature and with decreasing strain rate. This behavior was attributed to the competing effects of work hardening and dynamic recovery processes. The Sn-2.0Ag-0.5Cu-0.05Ni solder displayed the highest mechanical properties due to the formation of hard (Cu,Ni)6Sn5 IMCs. Based on the obtained stress exponents and activation energies, it is suggested that the dominant deformation mechanism in SAC (205)-, SAC (0505)- and SAC (0505)-0.05Ni solders is pipe diffusion, and lattice self-diffusion in SAC (205)-0.05Ni solder. In view of these results, the Sn-2.0Ag-0.5Cu-0.05Ni alloy is a more reliable solder alloy with improved properties compared with other solder alloys tested in the present work.

Similar content being viewed by others

References

Y.A. Su, L.B. Tan, T.Y. Tee, and V.B.C. Tan, Microelectron. Reliab. 50, 564 (2010).

S.H. Wang, T.S. Chin, C.F. Yang, S.W. Chen, and C.T. Chuang, J. Alloys Compd. 497, 428 (2010).

H. Jiang, K. Moon, and C.P. Wong, Microelectron. Reliab. 53, 1968 (2013).

H. Ye, S. Xue, J. Luo, and Y. Li, Mater. Des. 46, 816 (2013).

K.C. Otiaba, R.S. Bhatti, N.N. Ekere, S. Mallik, and M. Ekpu, Eng. Fail. Anal. 28, 192 (2013).

V.L. Niranjani, B.S.S. Chandra Rao, Vajinder Singh, and S.V. Kamat, Mater. Sci. Eng. A 529, 257 (2011).

S. Chantaramanee, S. Wisutmethangoon, L. Sikong, and T. Plookphol, J. Mater. Sci.: Mater. Electron. 24, 3707 (2013).

D. Li, C. Liu, and P.P. Conway, Mater. Sci. Eng. A 391, 95 (2005).

Y.C. Chan and D. Yang, Prog. Mater. Sci. 55, 428 (2010).

H. Ma and T.K. Lee, IEEE Trans. Compon. Packag. 3, 71 (2013).

D.A. Shnawah, M.F.M. Sabri, I.A. Badruddin, S.B.M. Said, T. Ariga, and F.X. Che, J. Electron. Mater. 42, 470 (2013).

David B. Witkin, Mater. Sci. Eng. A 532, 212 (2012).

R. Pandher and R. Healey, Proceedings of the 58th Electronic Components and Technology Conference, IEEE (Lake Buena Vista, FL, 2008), p. 2018.

U.S. Mohanty and K.L. Lin, J. Electron. Mater. 42, 628 (2013).

W. Dong, Y. Shi, Y. Lei, Z. Xia, and F. Guo, J. Mater. Sci.: Mater. Electron. 20, 1008 (2009).

F. Cheng, H. Nishikawa, and T. Takemoto, J. Mater. Sci. 43, 3643 (2008).

A.A. El-Daly, A.E. Hammad, A. Fawzy, and D.A. Nasrallh, Mater. Des. 43, 40 (2013).

D. Suh, D.W. Kim, P. Liu, H. Kim, J.A. Weninger, and C.M. Kumar, et al., Mater. Sci. Eng. A 460–461, 595 (2007).

F.X. Che, W.H. Zhu, S.W. Poh Edith, X.W. Zhang, and X.R. Zhang, J. Alloys Compd. 507, 215 (2010).

T. Ventura, S. Terzi, M. Rappaz, and A.K. Dahle, Acta Mater. 59, 1651 (2011).

D.-S. Jiang, Y.-P. Wang, and C.S. Hsiao, Proceedings of the 8th Electronics Packaging Technology Conference, IEEE (Singapore, 2007), p. 385.

A.A. El-Daly and A.E. Hammad, J. Alloys Compd. 509, 8554 (2011).

G. Montesperelli, M. Rapone, F. Nanni, P. Travaglia, P. Riani, and R. Marazza, et al., Mater. Corros. 59, 662 (2008).

H.Y. Song, Q.S. Zhu, Z.G. Wang, J.K. Shang, and M. Lu, Mater. Sci. Eng. A 527, 1343 (2010).

G.Y. Li, B.L. Chen, X.Q. Shi, S.C.K. Wong, and Z.F. Wang, Thin Solid Films 504, 421 (2006).

A.A. El-Daly, A. Fawzy, A.Z. Mohamad, and A.M. El-Taher, J. Alloys Compd. 509, 4574 (2011).

J. Zhang, B. Chen, and B. Zhang, Mater. Des. 34, 15 (2012).

V. Senthilkumar, A. Balaji, and R. Narayanasamy, Mater. Des. 37, 102 (2012).

M.L. Huang, C.M.L. Wu, and L. Wang, J. Electron. Mater. 34, 1373 (2005).

S. Alibabaie and R. Mahmudi, Mater. Des. 39, 397 (2012).

C.M.L. Wu, D.Q. Yu, C.M.T. Law, and L. Wang, Mater. Sci. Eng. R 44, 1 (2004).

R. Mahmudi, A.R. Geranmayeh, H. Khanbareh, and N. Jahangiri, Mater. Des. 30, 574 (2009).

I. Shohji, T. Yoshida, T. Takahashi, and S. Hioki, Mater. Sci. Eng. A 366, 50 (2004).

N. Hidaka, H. Watanabe, and M. Yoshiba, J. Electron. Mater. 38, 670 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hammad, A., El-Taher, A. Mechanical Deformation Behavior of Sn-Ag-Cu Solders with Minor Addition of 0.05 wt.% Ni. J. Electron. Mater. 43, 4146–4157 (2014). https://doi.org/10.1007/s11664-014-3323-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3323-y