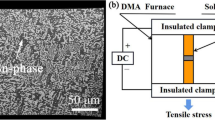

The work reported here included preliminary tests on the influence of an imposed current on the creep rate of the Pb-free solder Sn-Ag-Cu 305 (Sn-3Ag-0.5Cu in wt.%). The samples employed were double-shear specimens that contained paired solder joints, 400 μm × 400 μm in cross-section, 200 μm in thickness on Cu. Three tests were done. In the first, samples were tested under stress at room temperature with imposed current densities that ranged from 1 × 103 A/cm2 up to 6.5 × 103 A/cm2. As expected, because of Joule heating, the results show a sharp increase in creep rate with the imposed current density. A second set of tests was done to determine whether Joule heating fixed the creep rate. The steady-state temperature of the solder joints was measured under current, and samples were creep-tested at that temperature. Surprisingly, the creep rate under current was significantly below that measured in isothermal tests at the same temperature. The third set of tests studied the influence of microstructure. Samples were prepared with three starting microstructures: as cast, thermally aged by long-term isothermal exposure, and current aged by long-term exposure to a fixed current density. The three microstructures were then tested with and without current at two ambient temperatures. The different microstructures had very different creep rates in the absence of current but, surprisingly, imposing a current (5.5 × 103 A/cm2) increased the creep rate by very nearly the same factor (~7×) in every case. Neither of these results is well understood at this time.

Similar content being viewed by others

References

T.K. Lee, F. Hua, J.W. Morris. Electron. Mater. Lett. 2, 157 (2006)

W. Peng, E. Monlevade, and M. Marques, Microelectron. Reliab. 47, 2161 (2007)

S. Wiese, K.-J. Wolter. Microelectron. Reliab. 44, 1923 (2004) doi:10.1016/j.microrel.2004.04.016

S. Wiese, K.-J. Wolter. Microelectron. Reliab. 47, 223 (2007) doi:10.1016/j.microrel.2006.09.006

K. Yamanaka, Y. Tsukada, K. Suganuma. Microelectron. Reliab. 47, 1280 (2007) doi:10.1016/j.microrel.2006.09.028

H.G. Song, J.W. Morris, F. Hua. JOM 54, 30 (2002) doi:10.1007/BF02701846

S. Park, R. Dhakal, L. Lehman, E. Cotts. Acta Mater. 55, 3253 (2007) doi:10.1016/j.actamat.2007.01.028

J. Sundelin, S. Nurmi, T. Lepisto, E. Ristolainen. Mater. Sci. Eng. 420, 55 (2006) doi:10.1016/j.msea.2006.01.065

Acknowledgement

This research reports results from a joint project between the Component Quality and Technology Group, Cisco Systems and the University of California, Berkeley. Work at Berkeley was supported by Cisco Systems, and by the Korean Ministry of Commerce, Industry and Energy through Next-generation Microsystems Packaging Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kinney, C., Morris, J., Lee, TK. et al. The Influence of an Imposed Current on the Creep of Sn-Ag-Cu Solder. J. Electron. Mater. 38, 221–226 (2009). https://doi.org/10.1007/s11664-008-0568-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-008-0568-3