Abstract

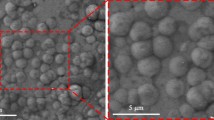

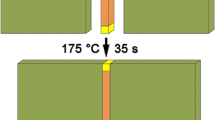

Nickel-based under bump metallization (UBM) has been widely used as a diffusion barrier to prevent the rapid reaction between the Cu conductor and Sn-based solders. In this study, joints with and without solder after heat treatments were employed to evaluate the diffusion behavior of Cu in the 63Sn-37Pb/Ni/Cu/Ti/Si3N4/Si multilayer structure. The atomic flux of Cu diffused through Ni was evaluated from the concentration profiles of Cu in solder joints. During reflow, the atomic flux of Cu was on the order of 1015–1016 atoms/cm2s. However, in the assembly without solder, no Cu was detected on the surface of Ni even after ten cycles of reflow. The diffusion behavior of Cu during heat treatments was studied, and the soldering-process-induced Cu diffusion through Ni metallization was characterized. In addition, the effect of Cu content in the solder near the solder/intermetallic compound (IMC) interface on interfacial reactions between the solder and the Ni/Cu UBM was also discussed. It is evident that the (Cu,Ni)6Sn5 IMC might form as the concentration of Cu in the Sn-Cu-Ni alloy exceeds 0.6 wt.%.

Similar content being viewed by others

References

L.F. Miller, IBM J. Res. Develop. 13, 239 (1969).

M.E. Loomans, S. Vaynaman, G. Ghosh, and M.E. Fine, J. Electron. Mater. 23, 741 (1994).

A.A. Liu, H.K. Kim, K.N. Tu, and P.A. Totta, J. Appl. Phys. 80, 2774 (1996).

H.K. Kim, K.N. Tu, and P.A. Totta, Appl. Phys. Lett. 68, 2204 (1996).

C.E. Ho, R. Zheng, G.L. Luo, A.H. Lin, and C.R. Kao, J. Electron. Mater. 29, 1175 (2000).

C.E. Ho, L.C. Shiau, and C.R. Kao, J. Electron. Mater. 31, 1264 (2002).

K.L. Lin and Y.C. Liu, IEEE Trans. Comp. Packaging 22, 575 (1999).

J.Y. Park, C.W. Yang, J.S. Ha, C.U. Kim, E.J. Kwon, S.B. Jung, and C.S. Kang, J. Electron. Mater. 30, 1165 (2001).

J.W. Jang, P.G. Kim, K.N. Tu, D.R. Frear, and P. Thompson, J. Appl. Phys. 85, 8456 (1999).

B.L. Young and J.G. Duh, J. Electron. Mater. 30, 878 (2001).

S.K. Kang et al., Proc. 51st Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2001), pp. 448–454.

R.G. Werner, D.R. Frear, J. DeRosa, and E. Sorongon, 1999 Int. Symp. on Advanced Packaging Materials (Reston, VA: IMAPS; Piscataway, NJ: IEEE, 1999), pp. 246–251.

C.S. Huang, J.G. Duh, Y.M. Chen, and J.H. Wang, J. Electron. Mater. 32, 89 (2003).

C.S. Huang and J.G. Duh, J. Mater. Res. 18, 935 (2003).

J.I. Goldstein, Scanning Electron Microscopy and X-ray Microanalysis (New York: Plenum Press, 1992), pp. 306–330.

C.S. Huang, G.Y. Jang, and J.G. Duh, J. Electron. Mater. 32, 1273 (2003).

H.K. Kim and K.N. Tu, Phys. Rev. B 53, 16027 (1996).

Y.C. Hsu and J.G. Duh, J. Electron. Mater., in press.

C.H. Lin, S.W. Chen, and C.H. Wang, J. Electron. Mater. 31, 907 (2002).

K.N. Tu and K. Zeng, Mater. Sci. Eng. R 34, 1 (2001).

M. Li, F. Zhang, W.T. Chen, K. Zeng, K.N. Tu, H. Balkan, and P. Elenius, J. Mater. Res. 17, 1612 (2002).

K. Zeng, V. Vuorinen, and J.K. Kivilahti, Proc. 51st Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2001), pp. 693–698.

C.E. Ho, R.Y. Tsai, Y.L. Lin, and C.R. Kao, J. Electron. Mater. 31, 584 (2002).

W.T. Chen, C.E. Ho, and C.R. Kao, J. Mater. Res. 17, 263 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Huang, CS., Jang, GY. & Duh, JG. Soldering-induced Cu diffusion and intermetallic compound formation between Ni/Cu under bump metallization and SnPb flip-chip solder bumps. J. Electron. Mater. 33, 283–289 (2004). https://doi.org/10.1007/s11664-004-0134-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-004-0134-6