Abstract

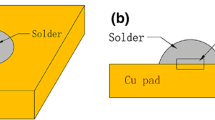

Long-term, solid-state intermetallic compound (IMC) layer growth was examined in 95.5Sn-3.9Ag-0.6Cu (wt.%)/copper (Cu) couples. Aging temperatures and times ranged from 70°C to 205°C and from 1 day to 400 days, respectively. The IMC layer thicknesses and compositions were compared to those investigated in 96.5Sn-3.5Ag/Cu, 95.5Sn-0.5Ag-4.0Cu/Cu, and 100Sn/Cu couples. The nominal Cu3Sn and Cu6Sn5 stoichiometries were observed. The Cu3Sn layer accounted for 0.4–0.6 of the total IMC layer thickness. The 95.5Sn-3.9Ag-0.6Cu/Cu couples exhibited porosity development at the Cu3Sn/Cu interface and in the Cu3Sn layer as well as localized “plumes” of accelerated Cu3Sn growth into the Cu substrate when aged at 205°C and t>150 days. An excess of 3–5at.%Cu in the near-interface solder field likely contributed to IMC layer growth. The growth kinetics of the IMC layer in 95.5Sn-3.9Ag-0.6Cu/Cu couples were described by the equation x=xo+Atnexp [−ΔH/RT]. The time exponents, n, were 0.56±0.06, 0.54±0.07, and 0.58±0.07 for the Cu3Sn layer, the Cu6Sn5, and the total layer, respectively, indicating a diffusion-based mechanism. The apparent-activation energies (ΔH) were Cu3Sn layer: 50±6 kJ/mol; Cu6Sn5 layer: 44±4 kJ/mol; and total layer: 50±4 kJ/mol, which suggested a fast-diffusion path along grain boundaries. The kinetics of Cu3Sn growth were sensitive to the Pb-free solder composition while those of Cu6Sn5 layer growth were not so.

Similar content being viewed by others

References

P. Vianco, Soldering Surf. Mount Technol. 14, 26 (2002).

P. Vianco, in Handbook of Lead (Pb)-Free Technology for Microelectronic Assembly (New York: Marcel-Dekker, 2004), pp. 167–210.

P. Vianco, P. Hlava, and A. Kilgo, J. Electron. Mater. 23, 583 (1994).

P. Vianco, K. Erickson, and P. Hopkins, J. Electron. Mater. 23, 721 (1994).

P. Vianco, A. Kilgo, and R. Grant, J. Electron. Mater. 24, 1493 (1995).

P. Vianco and J. Rejent, J. Electron. Mater. 28, 1131 (1999).

P. Vianco, P. Hlava, A. Kilgo, and J. Rejent, in Environmentally Friendly Electronics—Lead Free Technology, ed. J. Hwang (Ayr, UK: Electrochem Pub. Ltd., 2001) pp. 436–483.

P. Vianco, Soldering Handbook, 3rd ed. (Miami, FL: American Welding Society, 2000), p. 91.

E. Machlin, An Introduction to Aspects of Thermodynamics and Kinetics Relevant to Material Science (New York: McGraw-Hill, 1991), pp. 190–192.

P. Shewmon, Diffusion in Solids (Warrendale, PA: TMS, 1989), pp. 191–202.

T. Massalski, ed., Binary Alloy Phase Diagrams, Vol. 1 (Materials Park, OH: ASM, 1986), p. 965.

T. Massalski, ed., Binary Alloy Phase Diagrams, Vol. 1 (Materials Park, OH: ASM, 1986), p. 19.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Vianco, P.T., Rejent, J.A. & Hlava, P.F. Solid-state intermetallic compound layer growth between copper and 95.5Sn-3.9Ag-0.6Cu solder. J. Electron. Mater. 33, 991–1004 (2004). https://doi.org/10.1007/s11664-004-0026-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-004-0026-9