Abstract

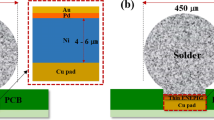

The wetting of I-Ag (immersion silver) and I-Sn (immersion tin) printed-circuit-board (PCB) finishes by Sn/Ag/Cu and eutectic Sn/Pb solders was studied in this work with Ni/Au (electroless nickel/immersion gold) and organic solderability preservative (OSP) finishes as baselines. Wetting tests were performed on fresh boards and boards subjected to different preconditioning treatments that simulated the effects of aging, storage, and multiple reflow cycles. When the boards are fresh, the wetting of the I-Sn and Ni/Au finishes is better than that on the I-Ag and OSP finishes. However, after the preconditioning treatments, the wetting of the I-Sn finish degrades the fastest, whereas the wetting of the I-Ag and OSP finishes degrade less through the different preconditioning treatments. The wetting of the Ni/Au finish remains excellent through all the preconditioning treatments. The chemical and microstructural changes in the finishes during aging treatments were evaluated using electron spectroscopy chemical analysis (ESCA), x-ray diffractometry (XRD), and cross-sectioning followed by scanning electron microscopy (SEM). The results indicate that a single lead-free reflow cycle consumes the I-Sn layer faster than a Sn/Pb reflow cycle because of the formation of the Sn/Cu intermetallic compound (IMC). Consequently, I-Sn finished boards having an original Sn thickness of ∼1 µm will not withstand multiple lead-free reflow cycles without significant degradation in wetting but up to two Sn/Pb reflow cycles are still feasible. The minimum thickness of I-Sn required for adequate wetting was evaluated by comparing the wetting after different aging treatments. The exposure of I-Sn samples to 85°C/85% relative humidity (RH) conditions increases the thickness of the Sn-oxide layer, which, above a certain thickness, can degrade wetting. Oxidized copper areas formed on top of the I-Ag surface after exposure to 85°C/85% RH treatment, and this was considered a major factor influencing wetting. The formation of sulfides on I-Ag was detected, but their overall quantity remained too small to have a detectable impact on the wetting.

Similar content being viewed by others

References

P.T. Vianco, Circuit World 25, 6 (1999).

B. Willis, Electron. Eng. 61 (1997).

S. Chada and E. Bradley III, Proc. SMTA Int. (Edina, MN: SMTA, 2001), pp. 604–611.

S. Lamprecht, H.-J. Scheier, and R. Vogel, Proc. SMTA Int. (Edina, MN: SMTA, 2002), pp. 508–515.

D.H. Ormerod, Circuit World 26, 11 (2000).

U. Ray, I. Artaki, and P.T. Vianco, IEEE Trans. Comp., Packaging, Manufacturing Technol. Part A 18, 153 (1995).

Institute for Interconnection and Packaging Electronics Circuits, IPC-A-610C Acceptability of Electronic Assemblies (Northbrook, IL: IPC, 2000).

Electronics Industries Alliance and Institute for Interconnection and Packaging Electronics Circuits, IPC/EIA J-STD-003A (Northbrook, IL: IPC, 2000).

J. Sundelin et al., to be published.

G. Beamson and D. Briggs, High Resolution XPS for Organic Polymers (London: John Wiley & Sons, 1992).

D. Xie, S. Yi, and C. Davidson, Proc. SMTA Int. (Edina, MN: SMTA, 2002), pp. 501–507.

P. Bratin, PC Fab 1 (2000).

C.R. Hicks, Fundamental Concepts in the Design of Experiments, 4th ed. (New York: Oxford University Press, Inc., 1993), pp. 56–63.

R.J.K. Wassink, Soldering in Electronics, 2nd ed. (Ayr, Scotland: Electrochemical Publications Ltd., 1989), p. 156.

J.S. Hwang, Environment-Friendly Electronics: Lead-Free Technology (Isle of Man, British Isles: Electrochemical Publications, 2001), pp. 446–450.

J.F. Moulder, W.F. Stickle, P.E. Sobol, and K.D. Bomben, in Handbook of X-Ray Photoelectron Spectroscopy, ed. J. Chastain and R.C. King, Jr. (Eden Prairie, MN: Physical Electronics, 1995).

Y. Limouzin-Maire, Bull. Soc. Chim. Fr. I, 340 (1981).

McDermid Inc., Sterling Silver Metallic Solderability Preservative—Silver Tarnish: Performance Effects & Prevention Techniques.

S.V. Sattiraju, B. Dang, R.W. Johnson, Y. Li, J.S. Smith, and M.J. Bozack, Proc. 51st Electronic Components and Technology Conf. (Piscataway, NJ: IEEE, 2001), pp. 1338–1344.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Arra, M., Shangguan, D., Xie, D. et al. Study of immersion silver and tin printed-circuit-board surface finishes in lead-free solder applications. J. Electron. Mater. 33, 977–990 (2004). https://doi.org/10.1007/s11664-004-0025-x

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-004-0025-x