Abstract

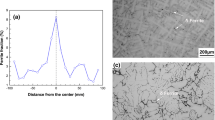

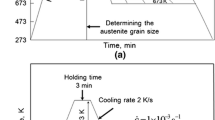

AISI 416 steel is a free-cutting stainless steel with a banded structure (BS) that is formed by element segregation, and its secondary phase particles significantly affect its microstructure and properties during the hot working process. In this study, we investigated the formation mechanism of the BS and its relationship with secondary phase particles (MnS and M23C6) in 416 steel by carrying out thermodynamic calculations and high-temperature confocal laser scanning microscopy, electron backscatter diffraction, scanning electron microscopy, and electron probe microanalyzer measurements. The BS was identified to be a delta-ferrite (δ-Fe) phase rich in Cr. In addition, when the volume fraction of δ-Fe was the largest during the solidification process (1392 °C, 1665 K) the BS was most likely to precipitate. The length and width of each grain in the BS were approximately 15 to 20 and 5 μm, respectively. The spacing between the BSs was in the range of 30 to 60 μm. The heat preservation treatment (1170 °C, 1443 K) of the steel could barely improve the shape of the BS. The fine M23C6 particles around the BS enhanced the segregation of Cr and worked with the MnS inclusions to pin the surrounding grains in order to prevent their coarsening during the heat preservation process. The metastable banded structure (MBS) formed near the BS transformed into a martensite phase because the concentration of the segregated Cr in the MBS was not sufficient to stabilize its microstructure. The MnS inclusions pinned and refined the grains and showed four types of distributions, namely between two grain boundaries, between polycrystalline boundaries, within the grains, and throughout the grains.

Similar content being viewed by others

References

X. Wu, L. Wu, J. Xie, P. Shen, J. Fu, Metall. Res. Technol. 117, pp. 1–8 (2020)

G. Domizzi, G. Anteri, J. Ovejero-Garcia, Corros. Sci. 43, 325–339 (2001)

R. Großterlinden, R. Kawalla, U. Lotter, H. Pircher, Steel Res. 63, 331–336 (1992)

A. Sarkissian, A. Karma, Mater. Sci. Eng. A 178, 153–157 (1994)

J.S. Kirkaldy, J. von Destinon-Forstmann, R.J. Brigham, Can. Metall. Q. 1, 59–81 (1962)

S.E. Offerman, N.H. van Dijk, MTh. Rekveldt, J. Sietsma, S. van der Zwaag, Mater. Sci. Technol. 18, 297–303 (2002)

W. Xu, P.E.J. Rivera-Diaz-Del-Castillo, S. van der Zwaag, ISIJ Int. 45, 380–387 (2005)

F. A. Khalid, M. Farooque, A. ul Haq, and A. Q. Khan: Mater Sci Technol, 1999, vol 15, pp 1209-15.

J.D. Verhoeven, J. Mater. Eng. Perform. 9, 286–296 (2000)

L. Shi, D.O. Northwood, J. Mater. Sci. 27, 5343–5347 (1992)

P.H.S. Cardoso, C. Kwietniewski, J.P. Porto, A. Reguly, T.R. Strohaecker, Mater. Sci. Eng. A 351, 1–8 (2003)

B. Krebs, L. Germain, A. Hazotte, M. Goune, J. Mater. Sci. 46, 7026–7038 (2011)

B. Wang, H.M. Hu, C. Zhou, Appl. Mech. Mater. 347–350, 1171–1175 (2013)

S.A. Etesami, M.H. Enayati, J. Mater. Eng. Perform. 25, 349–358 (2016)

D. You, S.K. Michelic, C. Bernhard, D. Loder, G. Wieser, ISIJ Int. 56, 1770–1778 (2016)

J. Miettinen, Metall. Mater. Trans. B 31B, 365–379 (2000)

T. Matsunaga, H. Hongo, M. Tabuchi, R. Sahara, Mater. Sci. Eng. A 655, 168–174 (2016)

H.X. Chi, D.S. Ma, H.X. Xu, W.L. Zhu, J.Q. Jiang, J. Iron Steel Res. Int. 23, 484–488 (2016)

K. Wang, T. Yu, Y. Song, H. Li, M. Liu, R. Luo, J. Zhang, F. Fang, X. Lin, Metall. Mater. Trans. B 50B, 1213–1224 (2019)

W. Mao, Z. An, S. Li, Chin. Sci. Bull. 54, 4537–4540 (2009)

P.A. Manohar, M. Ferry, T. Chandra, ISIJ Int. 38, 913–924 (2007)

R. Elst, J. van Humbeeck, L. Delaey, Acta Metall. 36, 1723–1729 (1988)

T. Gladman, Proc. R. Soc. Lond. A 294, 298–309 (1996)

N. Ryum, O. Hunderi, E. Nes, Scripta Metall. 17, 1281–1283 (1983)

C.T. Lin, Y.L. Shen, R. Becker, S. Suresh, Acta Mater. 47, 501–515 (1999)

Acknowledgments

The authors gratefully express their appreciation to Natural Science Foundation of China (Grant Nos. 51874195, and 52074179) for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 7, 2021; accepted April 6, 2021.

Rights and permissions

About this article

Cite this article

Tian, Q., Xu, X., Li, J. et al. Formation Mechanism of Band Delta-Ferrite in 416 Stainless Steel and Its Relationship with MnS and M23C6. Metall Mater Trans B 52, 2355–2363 (2021). https://doi.org/10.1007/s11663-021-02181-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02181-y