Abstract

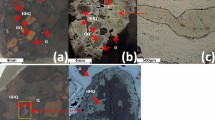

The interaction between mineral phases in two commercial iron ores and flux materials (CaO, MgO, SiO2, and Al2O3) was studied under 0.5 kPa O2 partial pressure while heating to different temperatures. CaO was the most effective flux for liquid phase generation during sintering. For a hematite ore with few gangue components (Ore A), the formation of an initial liquid phase commenced at ~ 1275 °C, with the liquid volume increasing dramatically as temperature increased to 1300 °C. For a goethite containing hematite ore (Ore B), the formation of an initial liquid phase through interaction between goethite and CaO was observed when heating to 1225 °C, with the majority of goethite transformed to liquid at 1250 °C. The porous morphology of sintered goethite and finely distributed quartz results in a high reactivity with CaO. The initial liquid phase penetrated into the pores within the hematite matrix, promoting assimilation and by 1300 °C, all hematite in Ore B was dissolved. The hematite/martite phase in Ore B was much easier to assimilate than that in Ore A due to the presence of goethite. MgO diffused into hematite ore grains by solid-state diffusion and formed a solid solution (Fe, Mg)O∙Fe2O3 without the formation of a liquid phase. The reaction layer formed by MgO diffusion was limited to approx. 60 μm at 1300 °C. The porous morphology in goethite facilitated MgO diffusion. However, the cavities and cracks caused by goethite dehydration significantly restricted solid phase diffusion of Mg2+. There was no observed interaction between Al2O3 and SiO2 with Ores A and B when heated to 1300 °C.

Similar content being viewed by others

References

J. Wang: Metallurgical Engineering, 2016, vol. 3, pp. 79-86.

S. Wu, H. L. Han, H. X. Li, J. Xu, S. D. Yang, and X. Liu: International Journal of Minerals, Metallurgy, and Materials, 2010, vol. 17, pp. 11-16.

Z. Xiao, L. Chen, Y. Yang, X. Li, and M. Barati: ISIJ International, 2017, vol. 57, pp. 795-804.

J. Clout and J. Manuel: Powder Technology, 2003, vol. 130, pp. 393-399.

R. Morris and M. Kneeshaw: Australian Journal of Earth Sciences, 2011, vol. 58, pp. 417-451.

C. E. Loo: ISIJ International, 2005, vol. 45, pp. 436-448.

C. E. Loo, L. T. Matthews, and D. P. O’dea: ISIJ International, 2011, vol. 51, pp. 930-938.

D. Debrincat and L. Ce: ISIJ International, 2004, vol. 44, pp. 1308-1317.

X. Guo and Y. Ono: Memoirs of the Faculty of Engineering Kyushu University, 1992, vol. 52, pp. 7-21.

H. Li: ISIJ International, 1989, vol. 29, pp. 24-32.

N. Oyama, T. Higuchi, S. Machida, H. Sato, and K. Takeda: ISIJ International, 2009, vol. 49, pp. 650-658.

Z. Wang, D. Pinson, S. Chew, B. J. Monaghan, H. Rogers, and G. Zhang: ISIJ International, 2016, vol. 56, pp. 505-512.

H. Li: ISIJ International, 1993, vol. 33, pp. 462-473.

E. Kasai, Y. Sakano, T. Kawaguchi, and T. Nakamura: ISIJ International, 2000, vol. 40, pp. 857-862.

H. Li, D. Pinson, P. Zulli, L. Lu, R. Longbottom, S. Chew, B. Monaghan, G. Zhang: Metallurgical and Materials Transactions B, 2018, vol. 49, pp. 2285-2297.

H. Li-Heng, J. A. Whiteman: ISIJ International, 1989, vol. 29, pp. 24-32.

H. Li, D. Pinson, P. Zulli, L. Lu, R. Longbottom, S. Chew, B. Monaghan, G. Zhang: Journal of Hazardous Materials, 2019, vol. 385(121592), pp. 1-13.

Y. Guo and X. Guo: ISIJ International, 2017, vol. 57, pp. 228-235.

V. D. Eisenhüttenleute and M. Allibert: Slag atlas, Verlag Stahleisen, Dusseldorf, Germany, 1995, pp. 70.

Z. Wang, D. Pinson, S. Chew, H. Rogers, B. J. Monaghan, G. Zhang: ISIJ International, 2016, vol. 56, pp. 1315-1324.

S. Wu, H. Han, W. Jiang, L. Zhu, G. Feng, Z. Zhang: Journal of University of Science and Technology Beijing, 2009, vol. 31, pp. 428-32.

E. W. Washburn: Physical Review, 1921, vol. 17, pp. 273-283.

R. M. German, Liquid Phase Sintering, Springer Science & Business Media, Berlin, Germany, 2013, pp. 13-41.

N. V. Scarlett, M. I. Pownceby, I. C. Madsen, and A. N. Christensen: Metallurgical and Materials Transactions B, 2004, vol. 35, pp. 929-936.

A. Cores, A. Babich, M. Muñiz, S. Ferreira, and J. Mochon: ISIJ International, 2010, vol. 50, pp. 1089-1098.

L. Ping, A. Azad and T.W. Dung: Materials research bulletin, 2001, vol. 36, pp. 1417-1430.

R. J. Borg and G. J. Dienes: An Introduction to Solid State Diffusion, Elsevier, Oxford, 2012, pp. 24-52.

M. E. Brown, D. Dollimore, and A. K. Galwey: Reactions in the Solid State, Elsevier, Amsterdam, 1980, pp. 41-109.

Acknowledgments

The authors gratefully acknowledge funding from the Australian Research Council Research Hub for Australian Steel Manufacturing (Project Number IH130100017) and the support of BlueScope Steel Ltd. The SEM/EDS observations were carried out at the Electron Microscopy Center of the University of Wollongong.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 3, 2020; accepted October 14, 2020.

Rights and permissions

About this article

Cite this article

Li, H., Pinson, D.J., Zulli, P. et al. Interaction Between Mineral Phases in a Hematite Iron Ore and Fluxing Materials During Sintering. Metall Mater Trans B 52, 267–281 (2021). https://doi.org/10.1007/s11663-020-02010-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-02010-8