Abstract

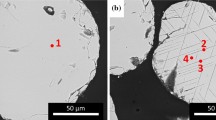

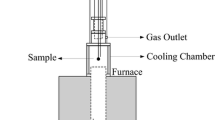

Direct reduction of iron ore pellets using hydrogen gas has the potential to significantly reduce CO2 emissions from the ironmaking process. In this work, green pellets of titanomagnetite ironsand from New Zealand were oxidatively sintered to form titanohematite. These sintered pellets were then reduced by H2 gas at temperatures ≥ 1043 K, and a maximum reduction degree of ~ 97 pct was achieved. Fully reduced pellets contained metallic Fe as the main product phase, but several different (Fe, Ti) oxides were also present as minor inclusions. The phase distribution of these oxides depended on the reduction temperature. With increasing temperature, the relative proportion of pseudobrookite in the final product increased, while the proportion of residual ilmenite and rutile decreased. The reduction kinetics were found to be well described by a pellet-scale single-interface shrinking core model, for reduction degrees up to 90 pct. At temperatures above 1143 K, the rate-limiting step was found to be solely an interfacial chemical reaction process, with a calculated apparent activation energy of 31.3 kJ/mol. For pellet sizes from 5.5 to 8.5 mm, the reaction rate was observed to increase linearly with decreasing pellet diameter, and this linear correlation extrapolated to intercept the axis at a pellet diameter of 2.5 mm. This is interpreted as the minimum length required for a shrinking core interface to develop within the pellet.

Similar content being viewed by others

References

1 H. Sun, A.A. Adetoro, Z. Wang, F. Pan, and L. Li: ISIJ Int., 2016, vol. 56, pp. 936–43.

2 R.L. Brathwaite, M.F. Gazley, and A.B. Christie: J. Geochemical Explor., 2017, vol. 178, pp. 23–34.

3 D.S. Chen, B. Song, L.N. Wang, T. Qi, Y. Wang, and W.J. Wang: Miner. Eng., 2011, vol. 24, pp. 864–9.

4 Y. Li, H. Guo, and L. Li: Chinese J. Eng., 2011, vol. 40, pp. 154–57.

A.A. Adetoro, H. Sun, S. He, Q. Zhu, and H. Li: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 846–57.

Iron and steel – Te Ara Encyclopedia of New Zealand, https://teara.govt.nz/en/iron-and-steel/page-2. Accessed 28 June 2017.

K.-H. Tacke and R. Steffen: 1st Chinese-German Seminar on Fundamentals of Iron and Steelmaking, Beijing, 2004.

8 V. Vogl, M. Åhman, and L.J. Nilsson: J. Clean. Prod., 2018, vol. 203, pp. 736–45.

9 A. Ranzani da Costa, D. Wagner, and F. Patisson: J. Clean. Prod., 2013, vol. 46(May), pp. 27–35.

S.W. Prabowo, R.J. Longbottom, B.J. Monaghan, D. del Puerto, M.J. Ryan, and C.W. Bumby: Metall. Mater. Trans. B, 2019, 50: 1729.

11 M.E. Choi and H.Y. Sohn: Ironmak. Steelmak., 2010, vol. 37, pp. 81–8.

12 E. Park and O. Ostrovski: ISIJ Int., 2003, vol. 43, pp. 1316–25.

R.J. Longbottom, O. Ostrovski, J. Zhang, and D. Young: Metall. Mater. Trans. B, 2007, vol. 38, pp. 175–84.

14 Y.L. Sui, Y.F. Guo, T. Jiang, X.L. Xie, S. Wang, and F.Q. Zheng: Int. J. Miner. Metall. Mater., 2017, vol. 24, pp. 10–7.

15 E. Park and O. Ostrovski: Isij Int., 2004, vol. 44, pp. 74–81.

16 E. Park and O. Ostrovski: ISIJ Int., 2004, vol. 44, pp. 999–1005.

17 J. Dang, G.H. Zhang, X.J. Hu, and K.C. Chou: Int. J. Miner. Metall. Mater., 2013, vol. 20, pp. 1134–40.

18 X.F. She, H.Y. Sun, X.J. Dong, Q.G. Xue, and J.S. Wang: J. Min. Metall. Sect. B Metall., 2013, vol. 49, pp. 263–70.

19 R.J. Longbottom, O. Ostrovski, and E. Park: ISIJ Int., 2006, vol. 46, pp. 641–6.

20 Z. Wang, J. Zhang, K. Jiao, Z. Liu, and M. Barati: J. Alloys Compd., 2017, vol. 729, pp. 874–83.

21 G.D McAdam, R.E.A Dall, T. Marshall: NEW Zeal. J. Sci., 1969, vol. 12, pp. 649–68.

J. Tang, M.S. Chu, Z.W. Ying, F. Li, C. Feng and Z.G. Liu: Metals (Basel)., 2017, vol. 7: 153.

23 Y.D. Wang, X.N. Hua, C.C. Zhao, T.T. Fu, W. Li, and W. Wang: Int. J. Hydrogen Energy, 2017, vol. 42, pp. 5667–75.

24 B. Hou, H. Zhang, H. Li, and Q. Zhu: Chinese J. Chem. Eng., 2015, vol. 23, pp. 974–80.

25 C. Li, H. Lin, Y. Chen: Thermochim. Acta, 2003, vol. 400, pp. 61–7.

26 A. Bonalde, A. Henriquez, and M. Manrique: ISIJ Int., 2005, vol. 45, pp. 1255–60.

M. Kazemi, M.S. Pour, and D. Sichen: Metall. Mater. Trans. B 48: 1114 (2017).

28 H. Zuo, C. Wang, J. Dong, K. Jiao, and R. Xu: Int. J. Miner. Metall. Mater., 2015, vol. 22, pp. 688–96.

B. Kennedy, N.H. Daniels, T. Marshall: N. Z. J. Sci., 1969, vol. 12, pp. 701–20.

A. Zhang, R.J. Longbottom, M. Nusheh, C.W. Bumby, and B.J. Monaghan: Proc. 8th International Congress on science and Technology of Ironmaking, Art. No. 282, Vienna, 2018.

Levenspiel O (1999) Chemical Reaction Engineering. Wiley, New York

32 P. den Hoed and A. Luckos: Oil Gas Sci. Technol., 2011, vol. 66, pp. 249–63

Acknowledgments

This research was supported by funding received from the Endeavour Fund of the New Zealand Ministry of Business Innovation and Employment (Grant No. RTVU1404)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, A., Monaghan, B.J., Longbottom, R.J. et al. Reduction Kinetics of Oxidized New Zealand Ironsand Pellets in H2 at Temperatures up to 1443 K. Metall Mater Trans B 51, 492–504 (2020). https://doi.org/10.1007/s11663-020-01790-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01790-3