Abstract

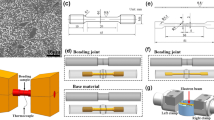

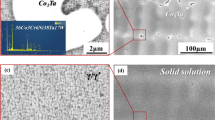

The novel metallurgical joining process for bonding IN718 superalloy was investigated by hot compressive bonding (HCB) process under the deformation temperature range of 1000 °C to 1150 °C and true strains ranging from 0 to 0.5 at a strain rate of 0.001 s−1. The effect of HCB process parameters on the tensile strength was analyzed. Both the as-deformed and the interfacial microstructures were characterized using the optical microscope, electron backscattered diffraction and transmission electron microscope (TEM) analysis. The results of tensile property revealed that the degree of metallurgical bonding is promoted by increasing deformation temperature and strain. The evolution of the interfacial microstructure showed that the migration of interfacial grain boundary (IGB), which is characterized by discontinuous dynamic recrystallization, is the dominant metallurgical bonding mechanism in the early stages of bonding. TEM analysis indicated that the dislocation density is distributed heterogeneously over both sides of IGB, which is the significant reason for the migration of IGB, during the initial stage of HCB process.

Similar content being viewed by others

Change history

18 July 2018

First Online: 21 June 2018

The authors would like to acknowledge the financial support given by the National Key Research and Development Program (Grant Number 2016YFB0300401), National Natural Science Foundation of China (Grant Number U1508215), Key Program of the Chinese Academy of Sciences (Grant Number ZDRW-CN-2017-1), and the National Natural Science Foundation of China (Grant Number 51774265). The authors would also like to thank Bijun Xie and Yifeng Guo for their help in the experimental work.

References

D. Furrer and H. Fecht: JOM., 1999, vol. 51, pp. 14-17.

D Locq, P Caron (2011) J. Aerosp. Lab 3:1.

A Mugarra, K Ostolaza, JL Alcaraz (2002) J. Mater. Process. Technol. 125–126:549-554.

R. E. Schafrik, D. D. Ward and J. R. Groh: Superalloys, 2001, vol. 1, pp.1-11.

K. D. Ramkumar, B. M. Kumar, M. G. Krishnan, S. Dev, A. J. Bhalodi, N. Arivazhagan and S. Narayanan: Mater. Sci. Eng. A, 2015, vol. 639, pp. 234-244.

S. K. Sharma, P. Agarwal and J. D. Majumdar: Procedia Manufacturing, 2016, vol. 7, pp. 654-659.

W. B. Han, K. F. Zhang, B. Wang, and D.Z. Wu: Acta Metall. Sin.-Engl., 2007, vol. 20, pp. 307-312.

A. A. Shirzadi and E. R. Wallach: Sci. Tech. Welding Joining, 2013, vol. 9, pp. 37-40.

G. Zhang, R. S. Chandel and H. P. Seow: Sci. Tech. Welding Joining, 2001, vol. 6, pp. 235-239.

T. J. Ma, X. Chen, W. Y. Li, X. W. Yang, Y. Zhang and S. Q. Yang: Mater. Design, 2016, vol. 89, pp. 85-93.

R. Damodaram, S. G. S. Raman, D. V. V. Satyanarayana, G. M. Reddy and K. P. Rao: Mater. Sci. Eng. A, 2014, vol. 612, pp. 414-422.

I. Woo, K. Nishimoto, K. Tanaka and M. Shirai: Welding International, 2000, vol. 14, pp. 365-374.

H. Kuroki: Welding International, 1999, vol. 13, pp. 945-951.

I. Sah, D. Kim, H. J. Lee and C. Jang: Mater. Design, 2013, vol. 47, pp. 581-589.

X. Gao, Z. Jiang, D. Wei, S. Jiao, D. Chen, J. Xu, X. Zhang, D. Gong: Mater. Design, 2014, vol. 63, pp. 650-657.

C. Sun, L. Li, M. Fu, Q. Zhou: Mater. Design, 2016, vol. 94, pp. 433-443.

X. Yang, W. Li, Y. Feng, S. Yu, B. Xiao: Mater. Design, 2016, vol. 104, pp. 436-452.

X. P. Wei, W. J. Zheng, Z. G. Song, T. Lei, Q. L. Yong and Q. C. Xie: J. Wuhan Univ. Technol., 2014, vol. 29, pp. 379-383.

T. Sakai: J Mater. Process. Technol., 1995, vol. 53, pp. 349-361.

D. Ponge, G. Gottstein: Acta Mater., 1998, vol. 46, pp. 69-80.

I. L. Dillamore, H. Katoh: Metal Science, 1974, vol. 8, pp. 73-83.

C. Zhang, H. Li and M. Q. Li: Sci. Technol. Welding Joining, 2015, vol. 20, pp. 115-122.

B. Alemán, L. Gutiérrez and J. J. Urcola: J. Mater. Sci. Technol. 2013, vol. 9, pp. 633-641.

Y. Zhou, W. F. Gale and T. H. North: Int. Mater. Rev., 1995, vol. 40, pp. 181-196.

H. J. McQueen: Mater. Sci. Eng. A, 2004, vol. 387, pp. 203-208.

S. M. F. Varzaneh, A. Z. Hanzaki, J. M. Cabrera and P. R. Calvillo: Mater. Chem. Phys., 2015, vol. 149, pp. 339-343.

Z. Yanushkevich, A. Belyakov and R. Kaibyshev: Acta Mater., 2015, vol. 82, pp. 244-254.

M. G. Jiang, H. Yan and R. S. Chen: J. Alloy. Compd., 2015, vol. 650, pp. 399-409.

T. Sakai, H. Miura, A. Goloborodko and O. Sitdikov: Acta Mater., 2009, vol. 57, pp. 153-162.

H. S. Lee, J. H. Yoon and W. H. Cho: Advanced Materials Research, 2011, vol. 228-229, pp. 666-671.

Acknowledgments

The authors would like to thank Bijun Xie and Yifeng Guo for their help in the experimental work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 31, 2017.

Rights and permissions

About this article

Cite this article

Zhang, J.Y., Sun, M.Y., Xu, B. et al. Interfacial Microstructural Evolution and Metallurgical Bonding Mechanisms for IN718 Superalloy Joint Produced by Hot Compressive Bonding. Metall Mater Trans B 49, 2152–2162 (2018). https://doi.org/10.1007/s11663-018-1313-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1313-9