Abstract

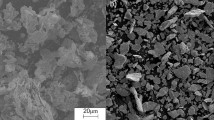

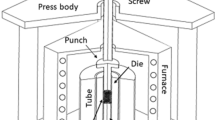

Aluminum and its alloys are key materials for the transportation industry as they contribute to the development of lightweight structures. The dispersion of hard ceramic particles in the Al soft matrix can lead to a substantial strengthening effect, resulting in composite materials exhibiting interesting mechanical properties and inspiring their technological use in sectors like the automotive and aerospace industries. Powder metallurgy techniques are attractive to design metal matrix composites, achieving a homogeneous distribution of the reinforcement into the metal matrix. In this work, pure aluminum has been reinforced with particles of niobium carbide (NbC), an extremely hard and stable refractory ceramic. Its use as a reinforcing phase in metal matrix composites has not been deeply explored. Composite powders produced after different milling times, with 10 and 20 vol pct of NbC were produced by high-energy ball milling and characterized by scanning electron microscopy and by X-ray diffraction to establish a relationship between the milling time and size, morphology, and distribution of the particles in the composite powder. Subsequently, an Al/10 pct NbC composite powder was hot extruded into cylindrical bars. The strength of the obtained composite bars is comparable to the commercial high-strength, aeronautical-grade aluminum alloys.

Similar content being viewed by others

References

J. Liu and M. Kulak: Mater. Sci. Forum, 2000, vols. 331-337, pp. 127-40.

W.H. Hunt Jr: Mater. Sci. Forum, 2000, vols. 331-337, pp. 71-84.

D.B. Miracle: Compos. Sci. Technol., 2005, vol. 65, pp. 2526-40.

C. Suryanarayana: Prog. Mater Sci., 2001, vol. 46, pp. 1-184.

J.S. Benjamin: Metall. Trans., 1970, vol. 1, pp. 2943-51.

P.R. Soni: Mechanical Alloying - Fundamentals and Applications, Cambridge International Science Publishing, Cambridge, U.K., 2001, pp. 35-51.

L. Lü and M.O. Lai: Mechanical Alloying, Kluwer Academic Publishers, New York, NY, 1998, pp. 1-9.

SherifEl-Eskandarany: Mechanical Alloying, Nanotechnology, Materials Science and Powder Metallurgy, 2nd ed., Noyes Publication, New York, 2015, pp. 13-47.

J. Abenojar, F. Velasco, J.M. Mota, and M.A. Martínez: J. Solid State Chem., 2004, vol. 177, pp. 382-8.

H. Ahamed and V. Senthilkumar: Mater. Charact., 2011, vol. 62, pp. 1235-49.

M.J. Tan and X. Zhang: Mater. Sci. Eng. A, 1998, vol. 244, pp. 80-5.

E.B. Tochaee, H.R. Hosseini, and S.M.S. Reihani: Mater. Sci. Eng. A, 2016, vol. 658, pp. 246-54.

M.H. Robert and J.C.V. Serra: Mechanical Characterization of Al-NbC Composites Produced by Powder Technology Route. Proceedings of the 1998 Powder Metallurgy World Congress: Granada, Spain. Edited by the European Powder Metallurgy Association, vol. 1, pp. 527–532, Shrewsbury, 1998.

H. Zuhailawati, R. Othman, B.D. Long, and M. Umemoto: J. Alloys Compd., 2008, vol. 464, pp. 185-9.

H. Zuhailawati and T.L. Yong: Mater. Sci. Eng. A, 2009, vol. 505, pp. 27-30.

B.D. Long, R. Othman, M. Umemoto, and H. Zuhailawati: J. Alloys Compd., 2010, vol. 505, pp. 510-5.

G.K. Williamson and W. Hall: Acta Metall., 1953, vol. 1, pp. 22-31.

M.P. Groover: Fundamentals of Modern Manufacturing: Materials, Processes and Systems, 5th ed., Wiley, Sussex, U.K., 2010, pp. 457-67.

T.H. Courtney and D. Maurice: Scripta Mater., 1996, vol. 34, pp. 5-11.

J.B. Fogagnolo, D. Amador, E.M. Ruiz-Navas, and J.M. Torralba: Mater. Sci. Eng. A, 2006, vol. 433, pp. 45-9.

S. Kamrani, A. Simchi, R. Riedel, and S.M. Seyed Reihani: Powder Metall., 2007, vol. 50, pp. 276-82.

N.A. Fleck, G.M. Muller, M.F. Ashby, and J.W. Hutchinson: Acta Metall. Mater., 1994, vol. 42, pp. 475-87.

SAE Aerospace Specification AMS2658C: Hardness and Conductivity Inspection of Wrought Aluminum Alloy Parts, SAE International, Warrendale, PA, 2009.

Metallic Materials Properties Development and Standardization (MMPDS-06), Batelle Memorial Institute, under license of the Federal Aviation Administration (FAA—USA), 2011.

Acknowledgments

The authors are thankful to Alcoa for supplying the Al powder and to Treibacher Industry AG for supplying the NbC, both of which are used in this work. The authors are also grateful to the Science and Technology Institute of the Federal University of São Paulo (ICT-UNIFESP) for making the development of this work feasible.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 21, 2016.

Rights and permissions

About this article

Cite this article

Travessa, D.N., Silva, M.J. & Cardoso, K.R. Niobium Carbide-Reinforced Al Matrix Composites Produced by High-Energy Ball Milling. Metall Mater Trans B 48, 1754–1762 (2017). https://doi.org/10.1007/s11663-017-0959-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0959-z